Method for prepn. of high concentration hydroxymaline in the prodn. process of hexanolactam

A production process, caprolactam technology, applied in the directions of hydroxylamine, nitrogen and non-metallic compounds, organic chemistry, etc., can solve problems such as low production efficiency, and achieve the effects of increasing unit consumption, reducing circulation, and reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

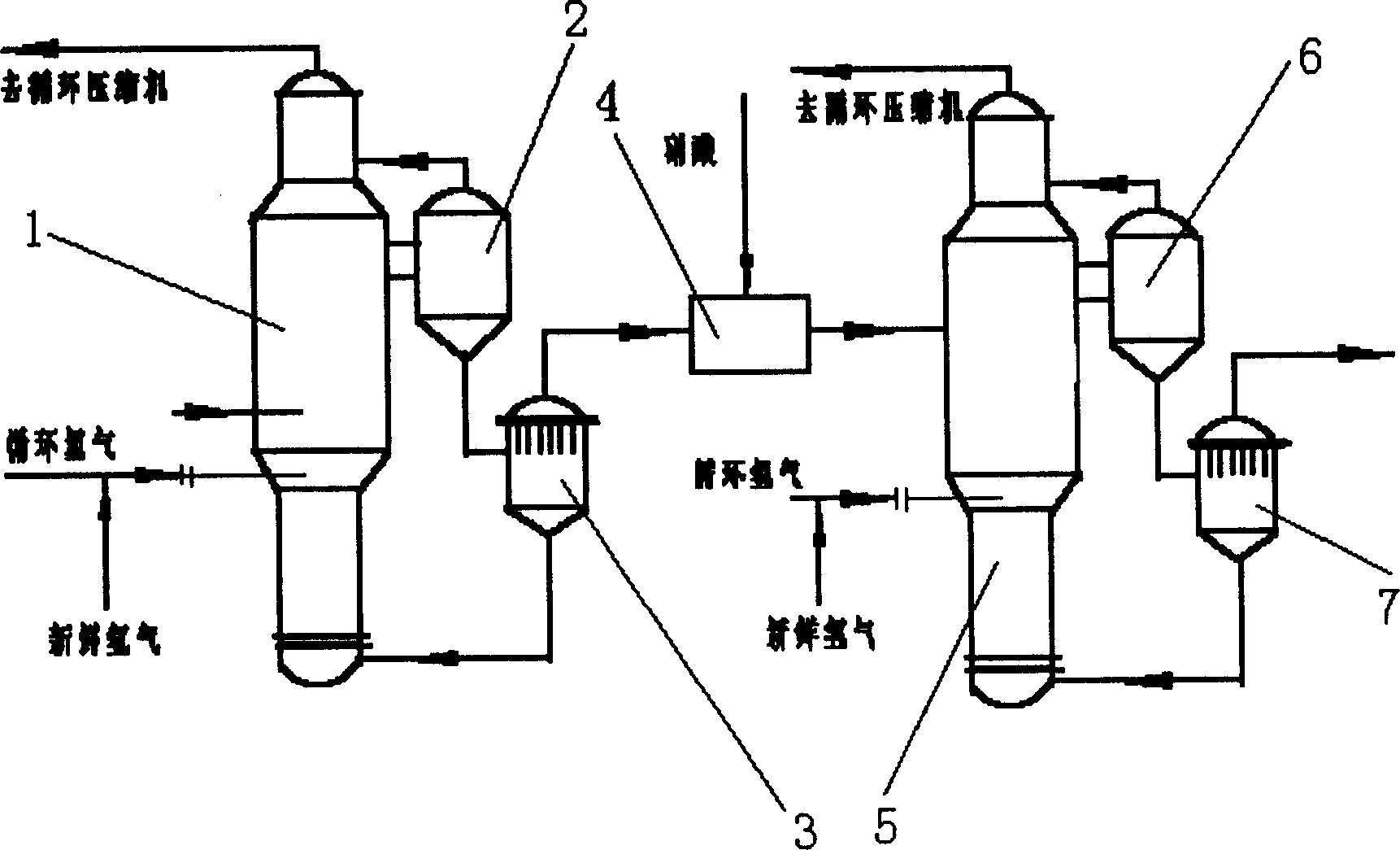

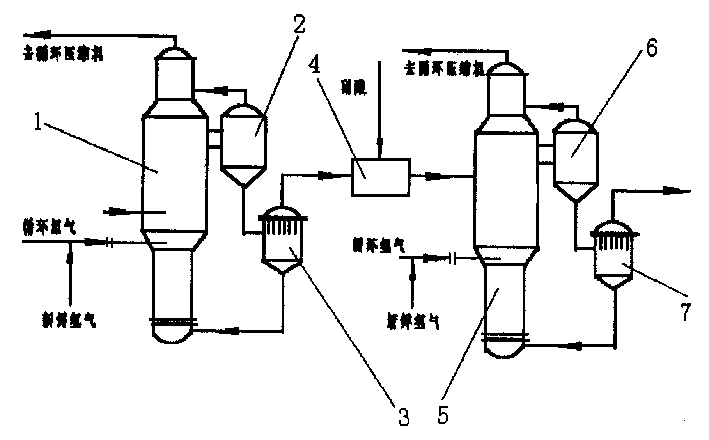

Image

Examples

Embodiment 1

[0021] The composition and content of the raw material inorganic liquid are H 3 PO 4 (20wt%), NH 3 OHH 2 PO 4 (0.75wt%), NH 4 NO 3 20wt%), HNO 3 (2.5wt%), H 2 O (55 wt%).

[0022] 90,000 kg / h of raw material inorganic liquid first enters the first reactor 1 from the middle and lower part of the reactor 1, and reacts with the hydrogen entering the bottom of the first reactor 1 in the presence of a catalyst to generate hydroxylamine with a concentration of 0.8mol / kg, the inorganic liquid containing hydroxylamine overflows from the top of the first reactor 1 and enters the first gas-liquid separator 2, the inorganic liquid containing low concentration hydroxylamine and a small amount of catalyst enters the first filter 3, and the filtered catalyst is sent back to the first filter In the first reactor 1, the inorganic liquid containing low-concentration hydroxylamine enters the mixer 4, mixes with the nitric acid that is supplemented, and then enters the middle and lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com