Method for automatically repairing crack, and apparatus therefor

An automatic repair and crack technology, applied in the field of cracks in components, can solve the problems of taking into account the situation of no branch cracks, the depth of cracks cannot be determined, the path of cracks cannot be judged, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

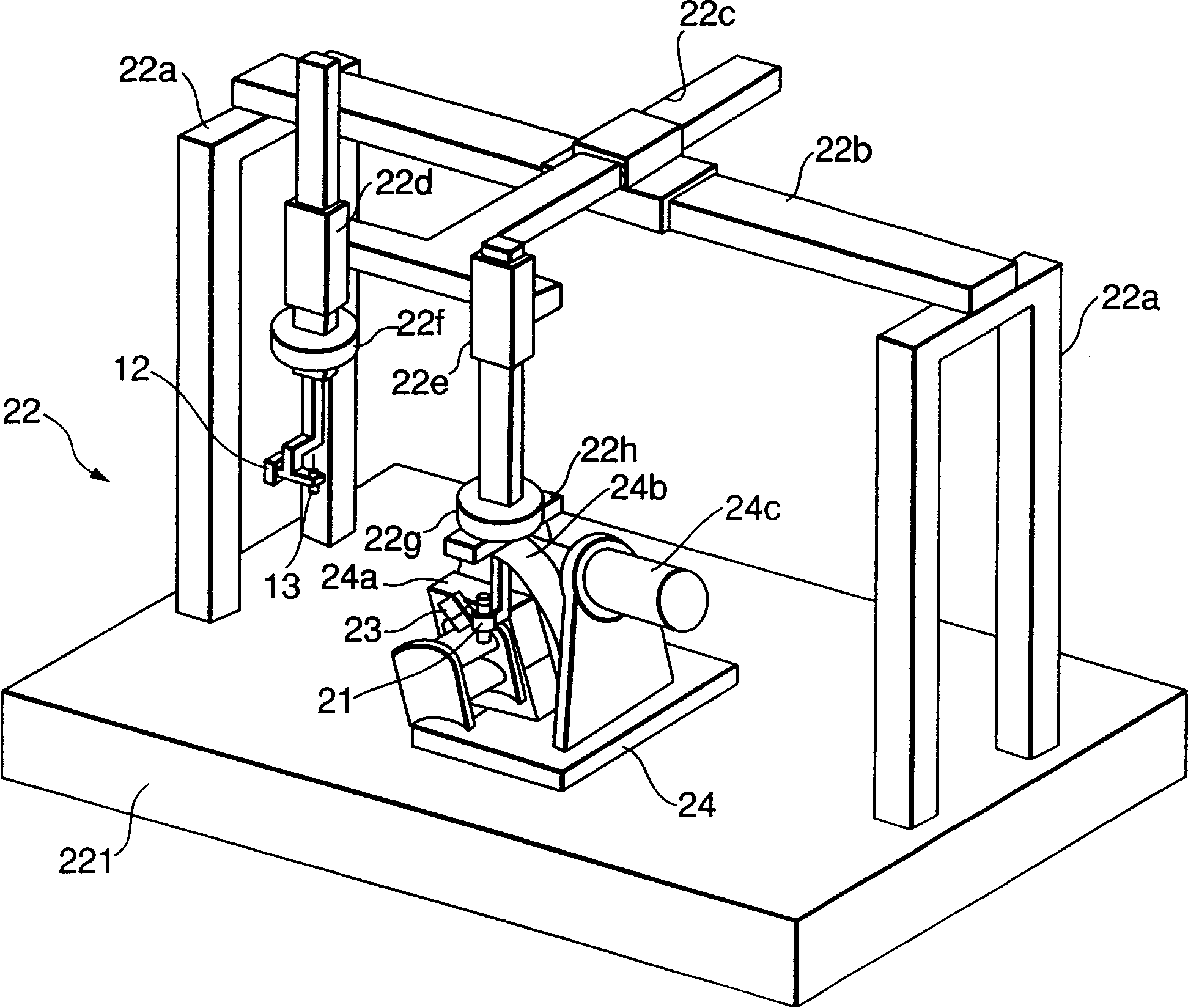

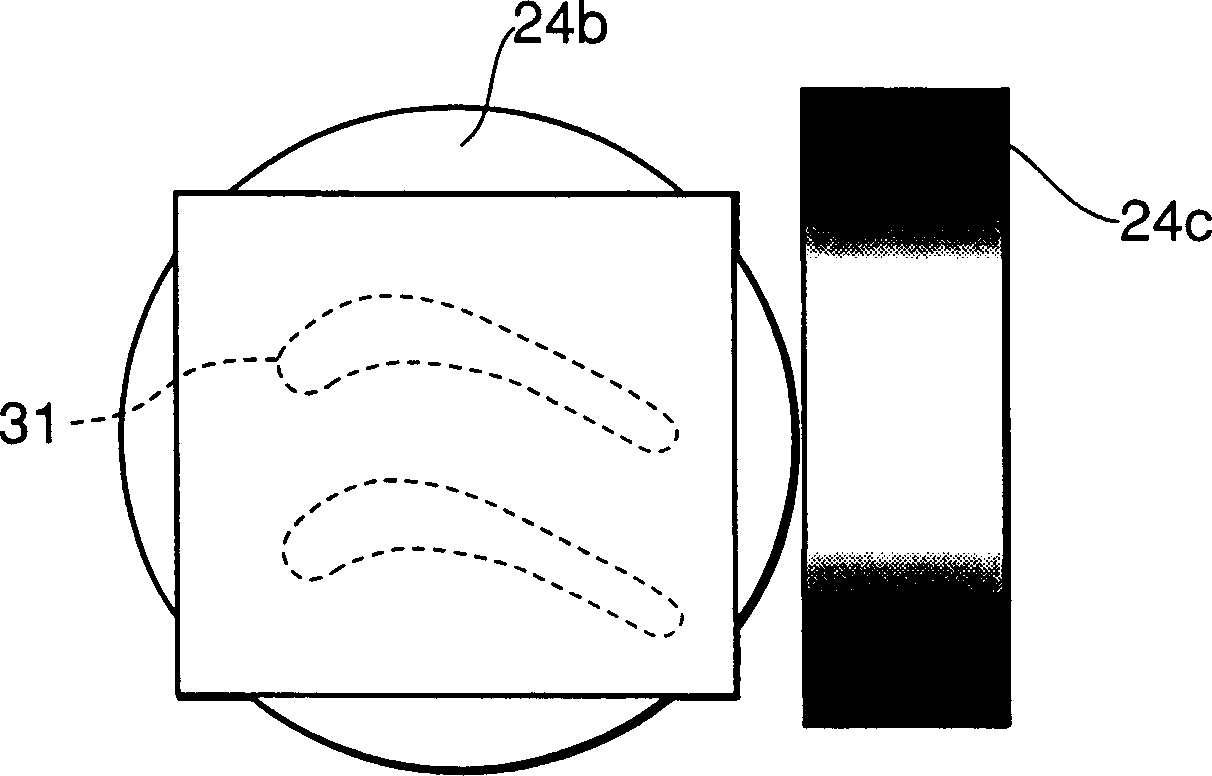

[0023] A preferred embodiment of the present invention will now be described in detail with reference to the accompanying drawings. However, unless otherwise specified, dimensions, materials, relative positions, etc., of constituent parts in the embodiments are illustrative only and are not to be considered as limiting the scope of the present invention.

[0024] Hereinafter, the present invention will be described by taking the repair of a crack generated on a turbine blade as an example, but the present invention can also be used for repairing parts other than turbine blades (parts to be repaired).

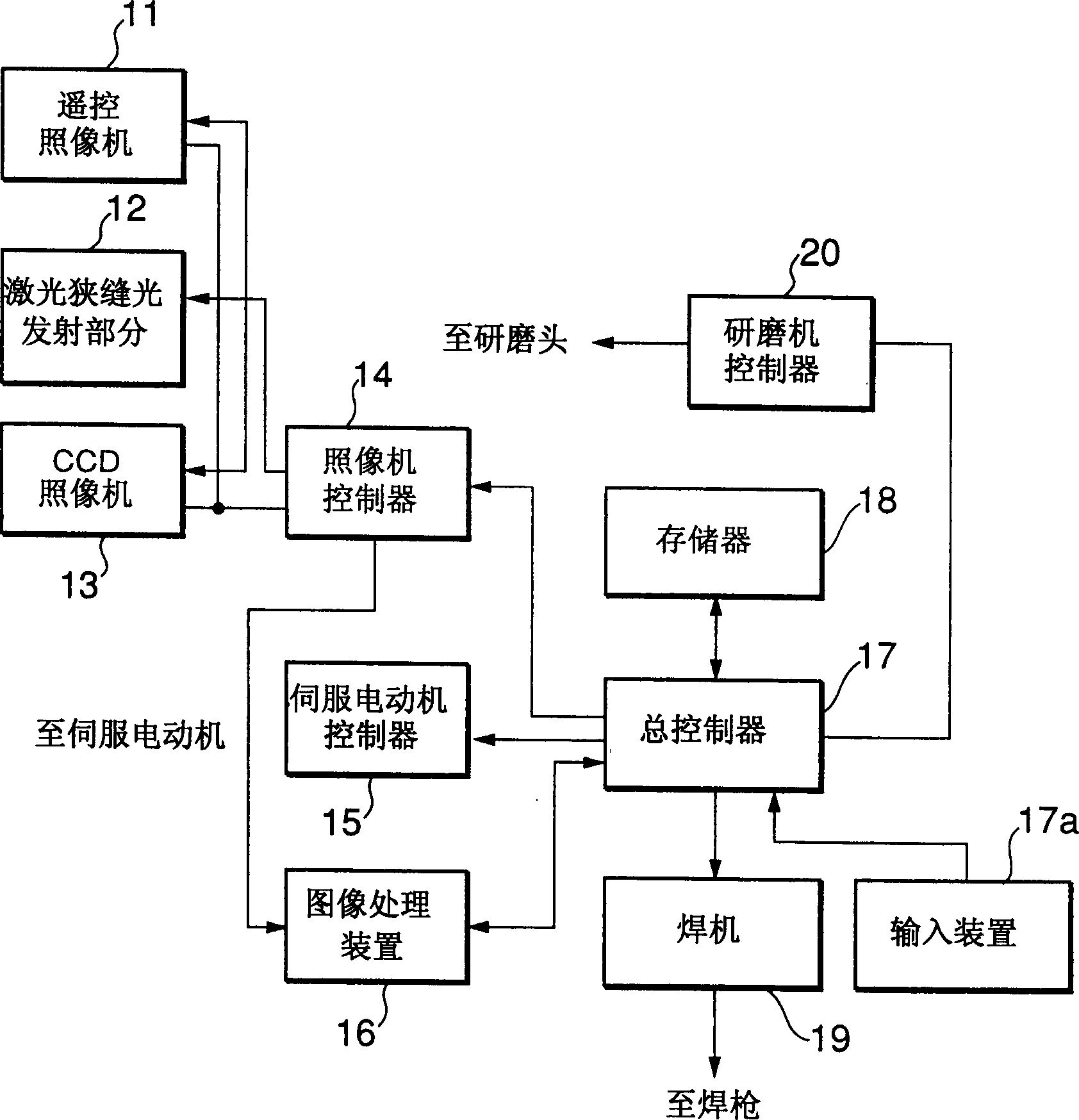

[0025] see figure 1 , The automatic crack repair equipment is provided with a remote camera 11, a laser slit light emitting part (laser slit sensor) 12, a CCD camera 13, a camera controller 14, a servo motor controller 15, and an image processing device 16 , master controller 17, input device 17a, memory 18, welder 19, grinder controller 20. When grinding, the general control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com