Construction method for prestressed piles and walls with deep foundation ditches being supported

A deep foundation pit support and prestressed pile technology, applied in sheet pile wall, foundation structure engineering, excavation and other directions, can solve the problems of large displacement of pile wall, high cost of structural materials, high requirements for hoisting equipment, and save steel bars. , saving investment costs, convenient production and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] 1. The unbonded steel strands described in the principles of the present invention can be unbonded steel strands of 7Φ3, 7Φ4, and 7Φ5 with a standard strength of more than 1470 MPa.

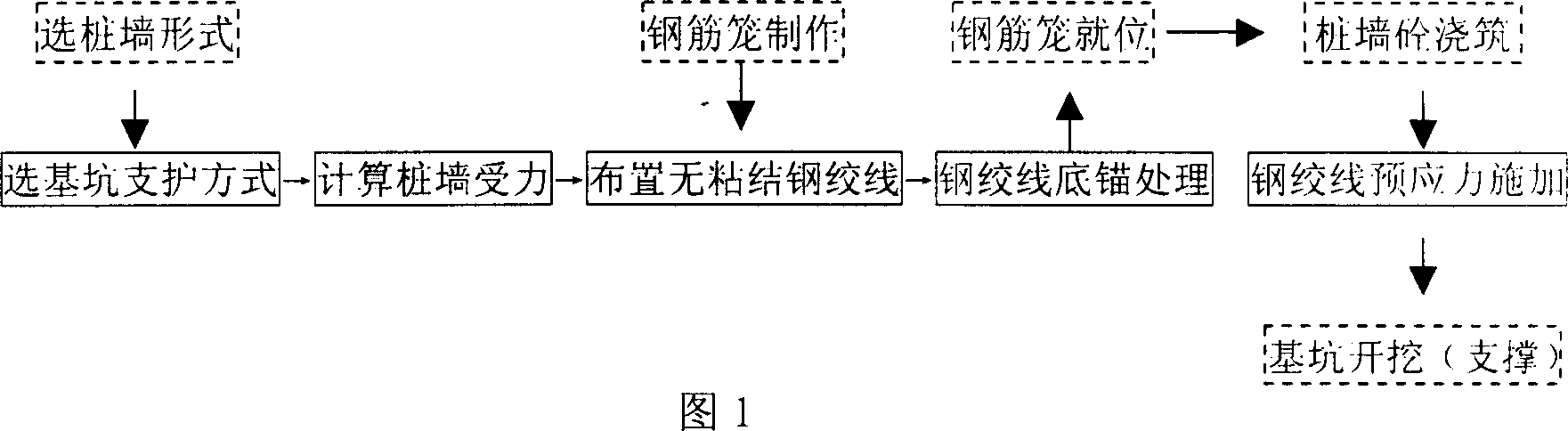

[0020] 2. Construction method description:

[0021] 2.1 Preliminary selection of the form of the pile wall: Calculate according to the surrounding terrain, landform and geological conditions of the foundation pit according to relevant specifications, and initially select the form of the pile wall, including the size of the pile wall, concrete label, and common reinforcement form, etc. In order to cooperate with the prestressing effect, the concrete grade is preferably above C40;

[0022] 2.2 Preliminary selection of the foundation pit support method: draft the support scheme adopted by the pile wall (cantilever scheme without support, or one or more support schemes);

[0023] 2.3 Calculation of the force of the pile wall: Check and calculate the force of the pile wall according to the for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com