Package method electronic ship made from wafen

An electronic chip and packaging method technology, which is applied in the directions of packaging, transportation and packaging, packaging/bundling items, etc., can solve the problems of inconvenience and inability to cover the peripheral surface of electronic chip components with packaging film, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

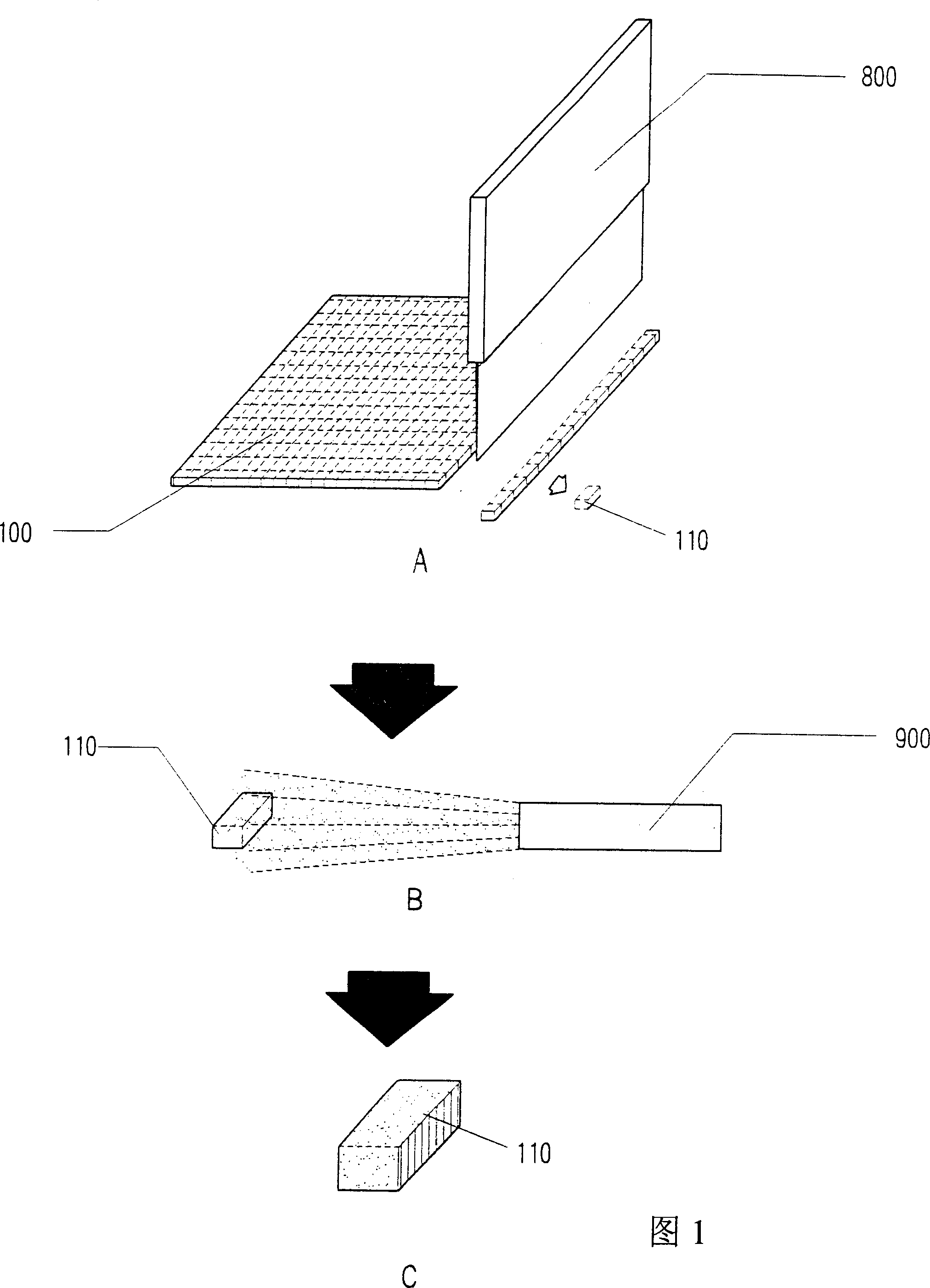

[0028] Among Fig. 1, A to C are schematic diagrams of the embodiment of the manufacturing method of conventional electronic chip components; its function and its shortcoming have been as previously mentioned, and will not be repeated here.

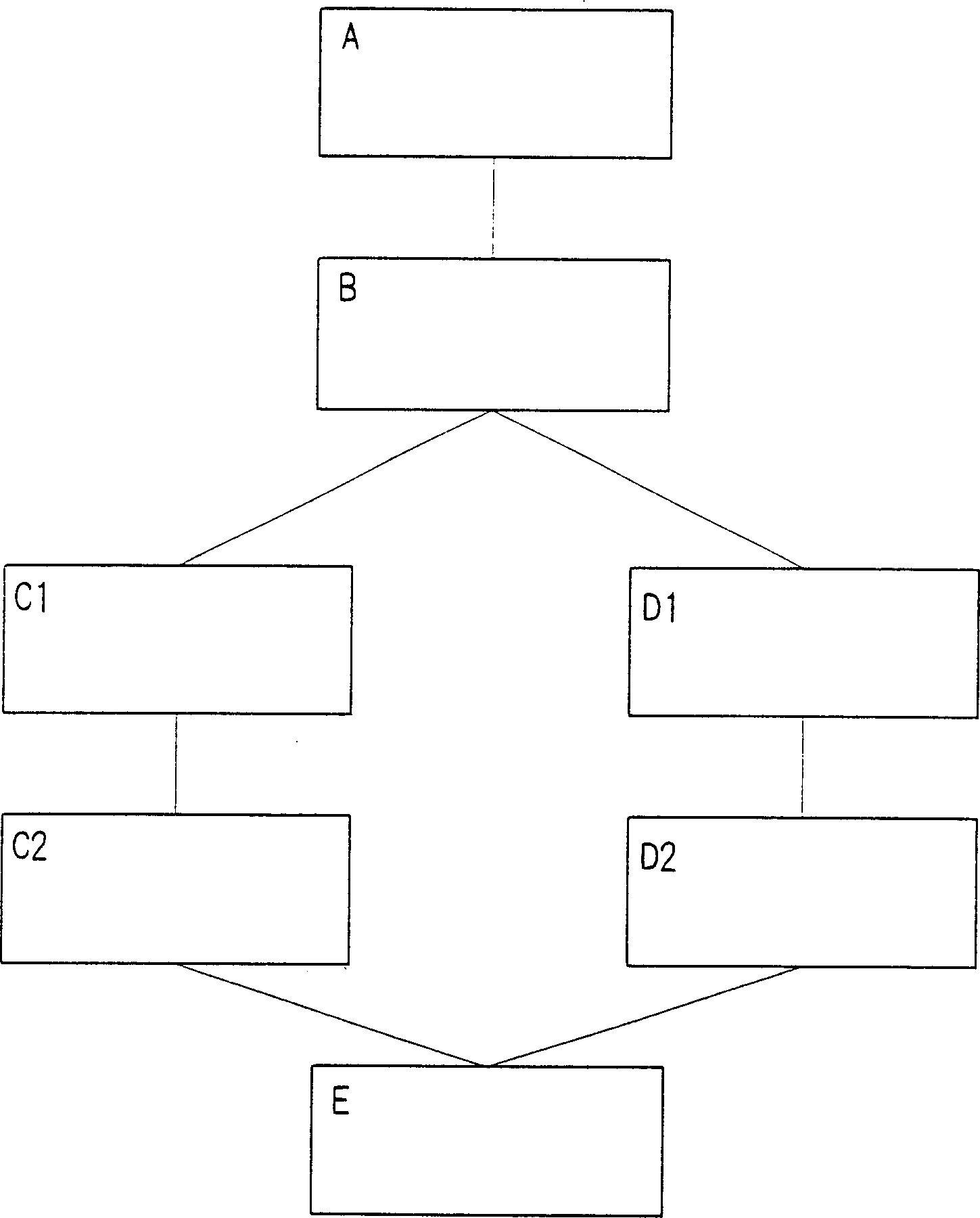

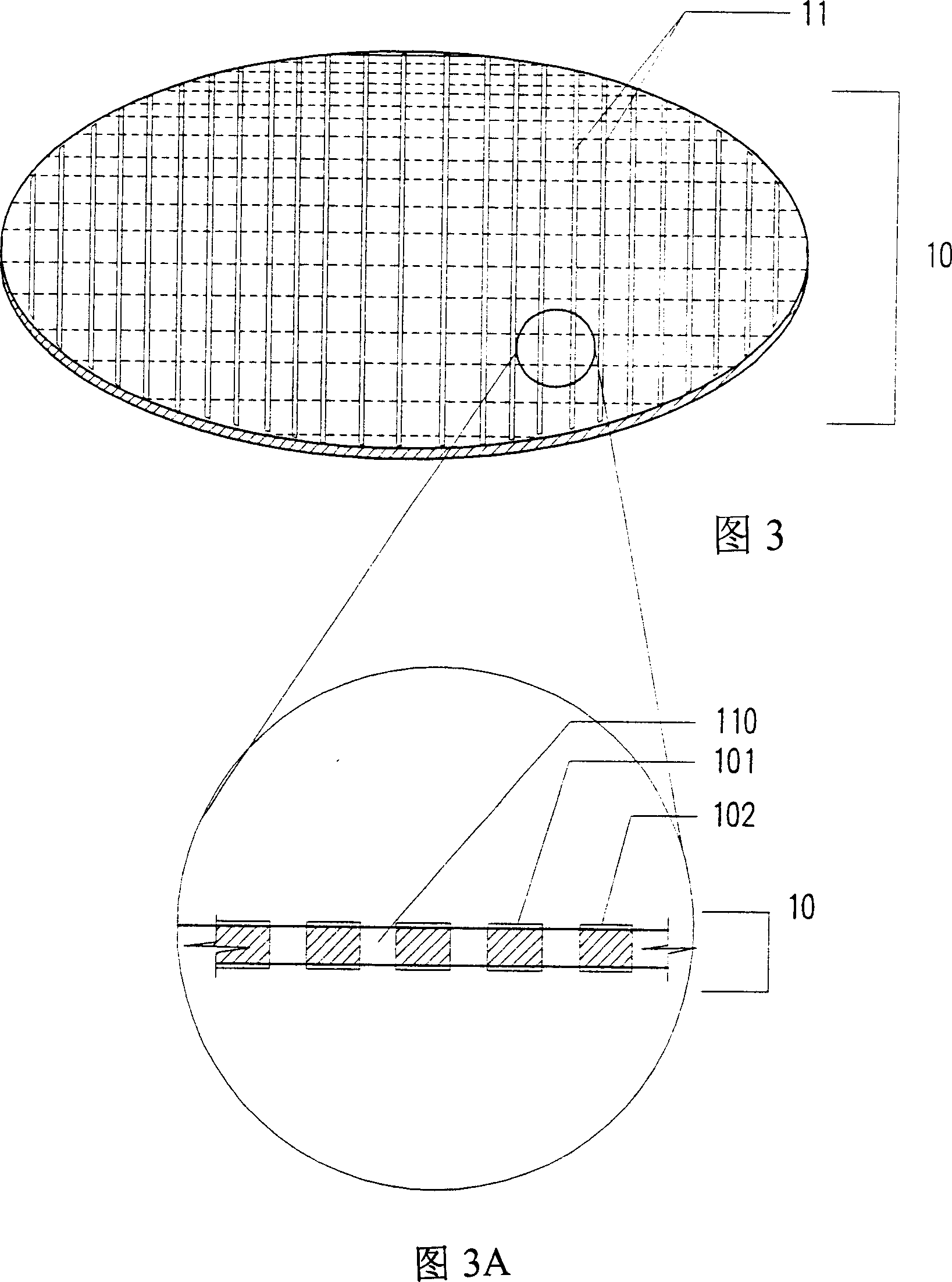

[0029] figure 2 It is a program diagram of this kind of packaging method for manufacturing electronic chip components with wafers of the present invention; as shown in this figure, the present invention includes multiple procedures: 1, earlier electronic chip components are made on wafers (wafer) , so that the electronic chip components are arranged at intervals (Procedure A), and two rows of electronic chip components arranged at intervals are separated by a distance (please refer to Figure 3); , according to the interval width of the electronic chip components on the wafer, etch out the elongated hole groove (procedure B); 3. By means of the vacuum lamination facility, coat the photoresist film on the wafer that has etched the elongated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com