Method for positioning on base and placing view-point characteristic of semiconductor piece

A substrate, viewpoint technology, used in semiconductor/solid-state device manufacturing, measurement devices, optical devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

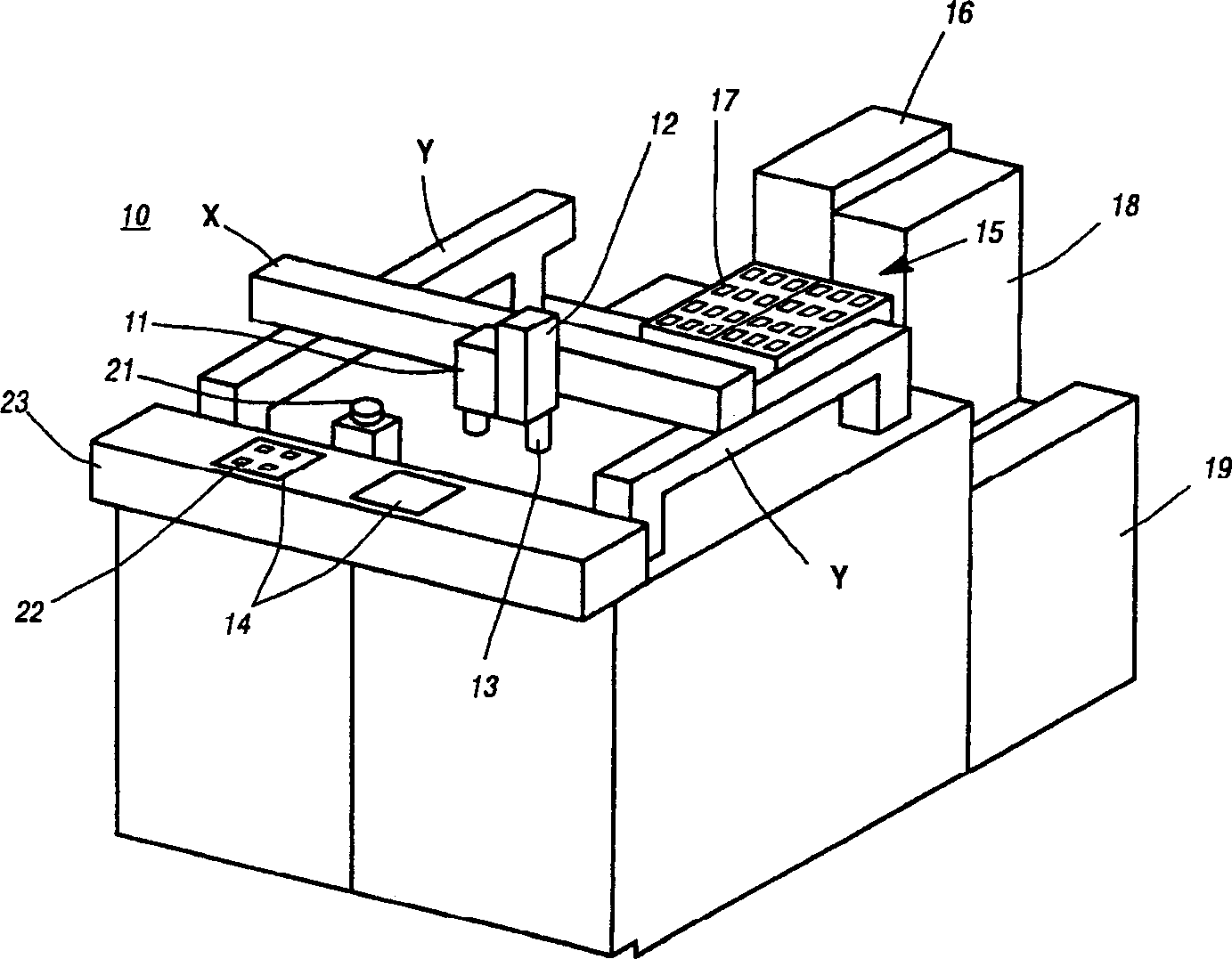

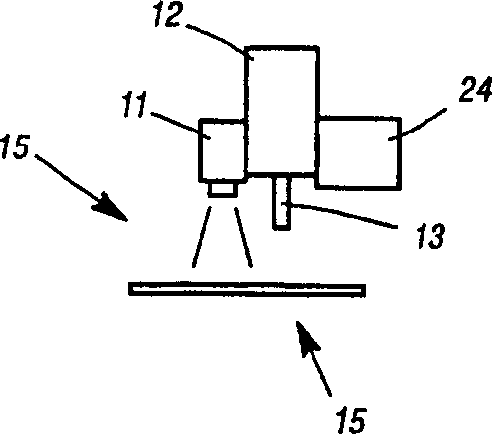

[0025] refer to figure 1 Shown is an isometric view of a typical prior art pick and place machine 10 with a downward looking camera 11 on a movable pick head 12 of the pick and place machine. The downward looking camera 11 serves several purposes. When the machine 10 is assembled, the video system and the camera 11 are used to determine the position of the pick-up nozzle 13 in the X-Y coordinate system of the machine 10, and to determine the position of the substrate 14 in the same coordinate system. The same camera is used to establish the position of the feed belt (not shown) pick station and to establish the position of the die tray 15 provided by the lift feed system 16 prior to picking the die or component 14 .

[0026] After the establishment is completed, the grid coordinates of the die tray 15 and the target position or placement position on the substrate 14 are known. What is not known is the exact position of the component 17 within the die tray 15 before picking, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com