Fuel water gasification combustion method

A combustion method and fuel oil technology, applied in combustion methods, liquid fuel supply/distribution, etc., can solve the problems of unstable emulsion combustion, unusable use, affecting use, etc., to eliminate nitrogen oxides (NOx, increase combustibles, combustion uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

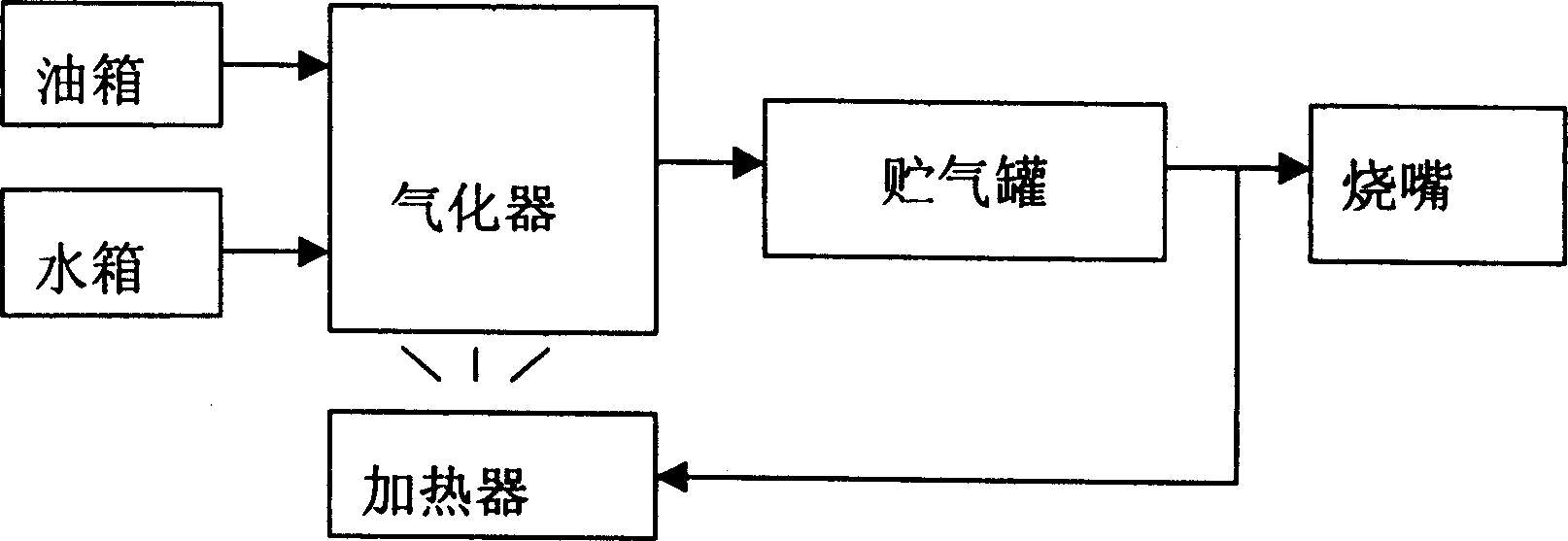

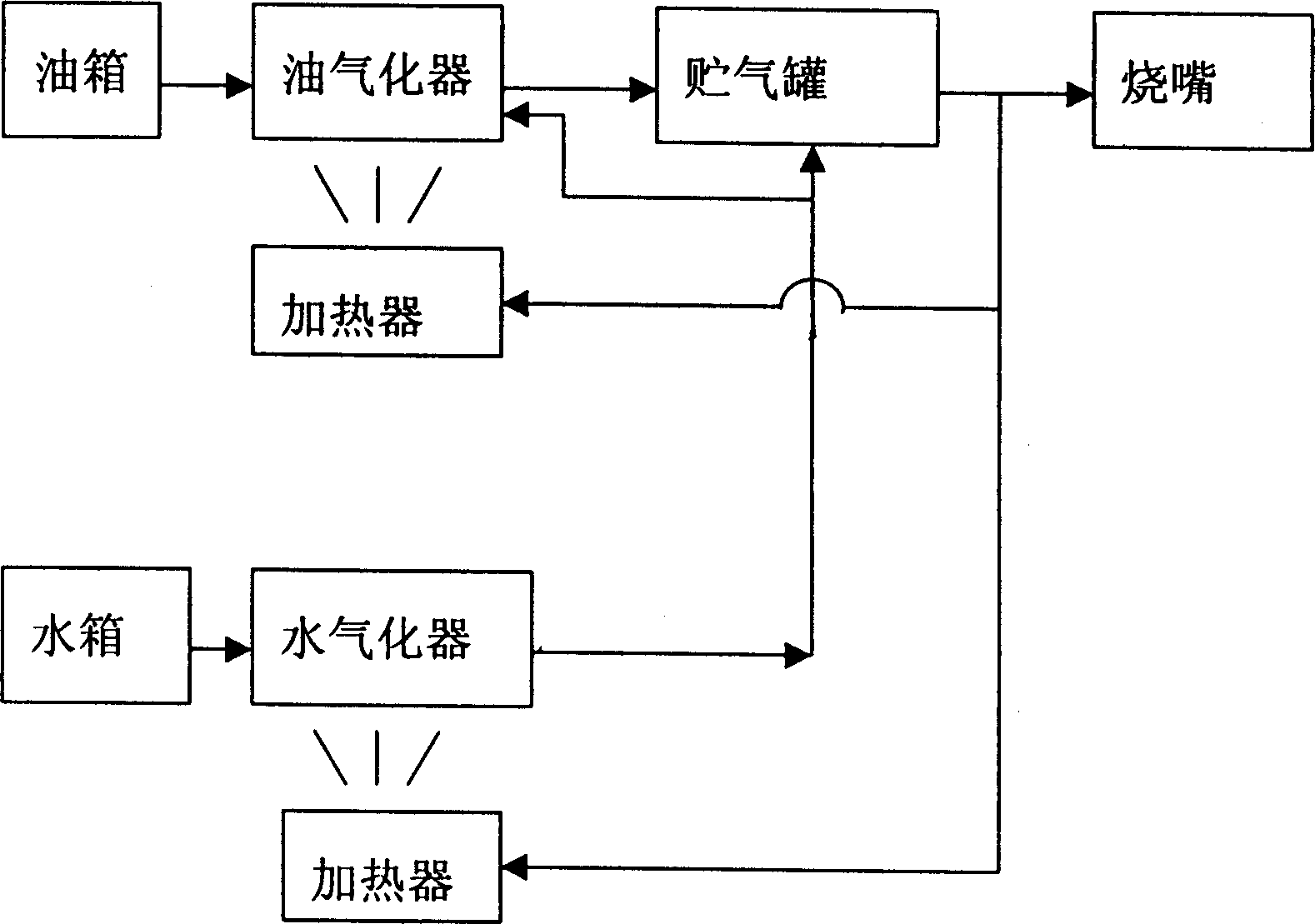

[0030] In accompanying drawing (1, 2), heater can burn other fuels such as coal gas, coal etc., also can burn other fuels to start heating, then get a part of oil-water mixture from gas storage tank, return to heater combustion.

[0031] Present embodiment is that the present invention is used on the diesel stove of civilian catering industry, is that oil, water are provided oil, water by the ratio of water mixing rate 15%-65% (weight ratio), carry out heating gasification, mixing, mixing The final oil-water mixture is sent to the burner for combustion.

[0032] In the present invention, the gasification heating temperature of oil and water is 400°C-1100°C; the preferred temperature range is 500°C-1000°C; 600°C-1000°C; 700°C-1000°C.

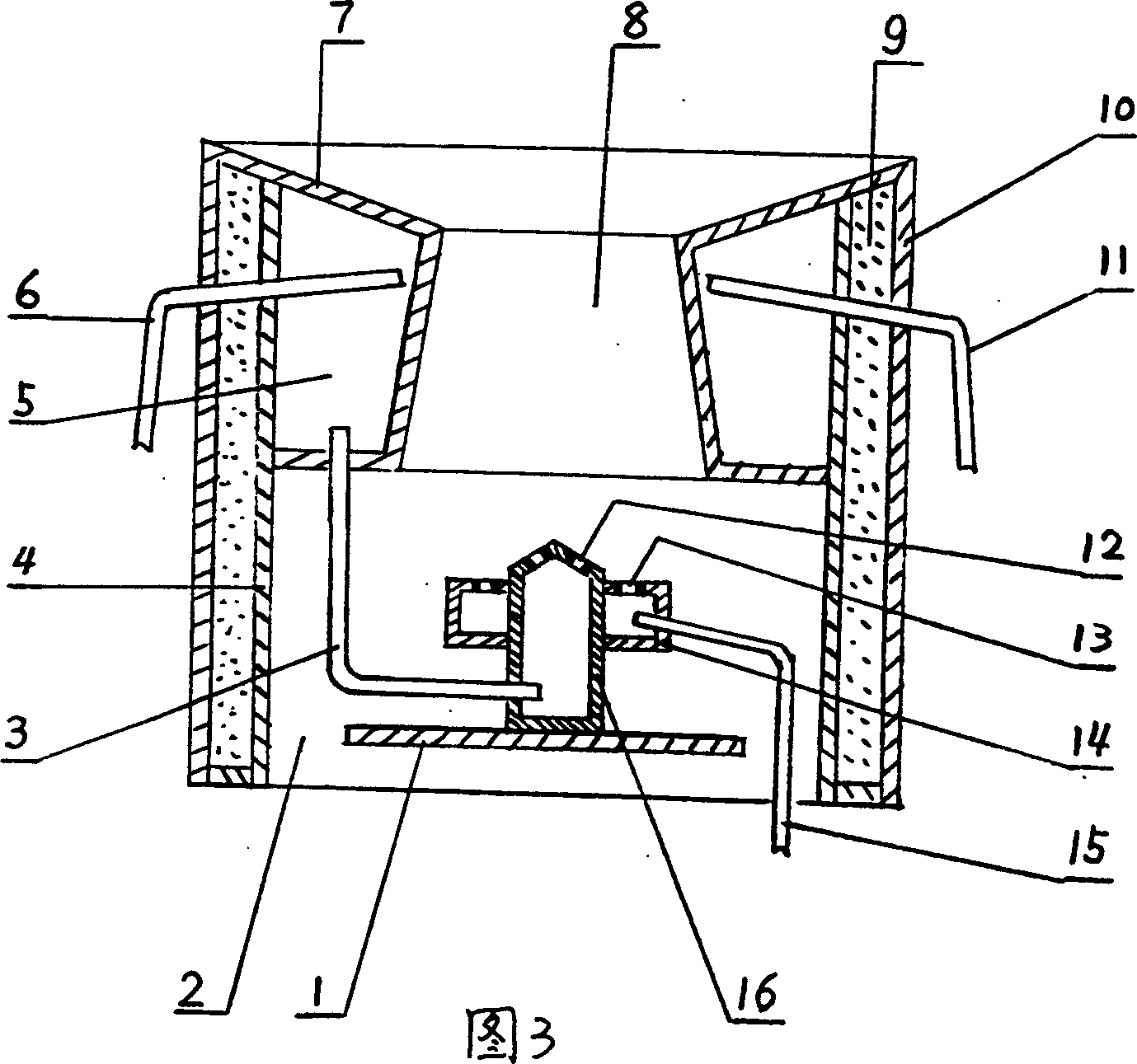

[0033] In the accompanying drawings, 1 is the chassis, 2 is the air inlet, 3 is the oil and gas pipe, 4 is the furnace cover, 5 is the gasifier, 6 is the oil inlet pipe, 7 is the furnace plate, 8 is the combustion chamber, 9 is the insulation lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com