Method and device for continuously treating synthetic fibers in heat exchange chamber

A heat exchange chamber and heat exchanger technology, which is applied in the processing of textile material containers, liquid/gas/vapor yarn/filament processing, textiles and papermaking, etc., can solve the problems of increasing the processing distance and reducing the heat exchange effect, etc. To achieve the effect of difficult pressure adjustment, simple operation and shortening of heat exchange distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

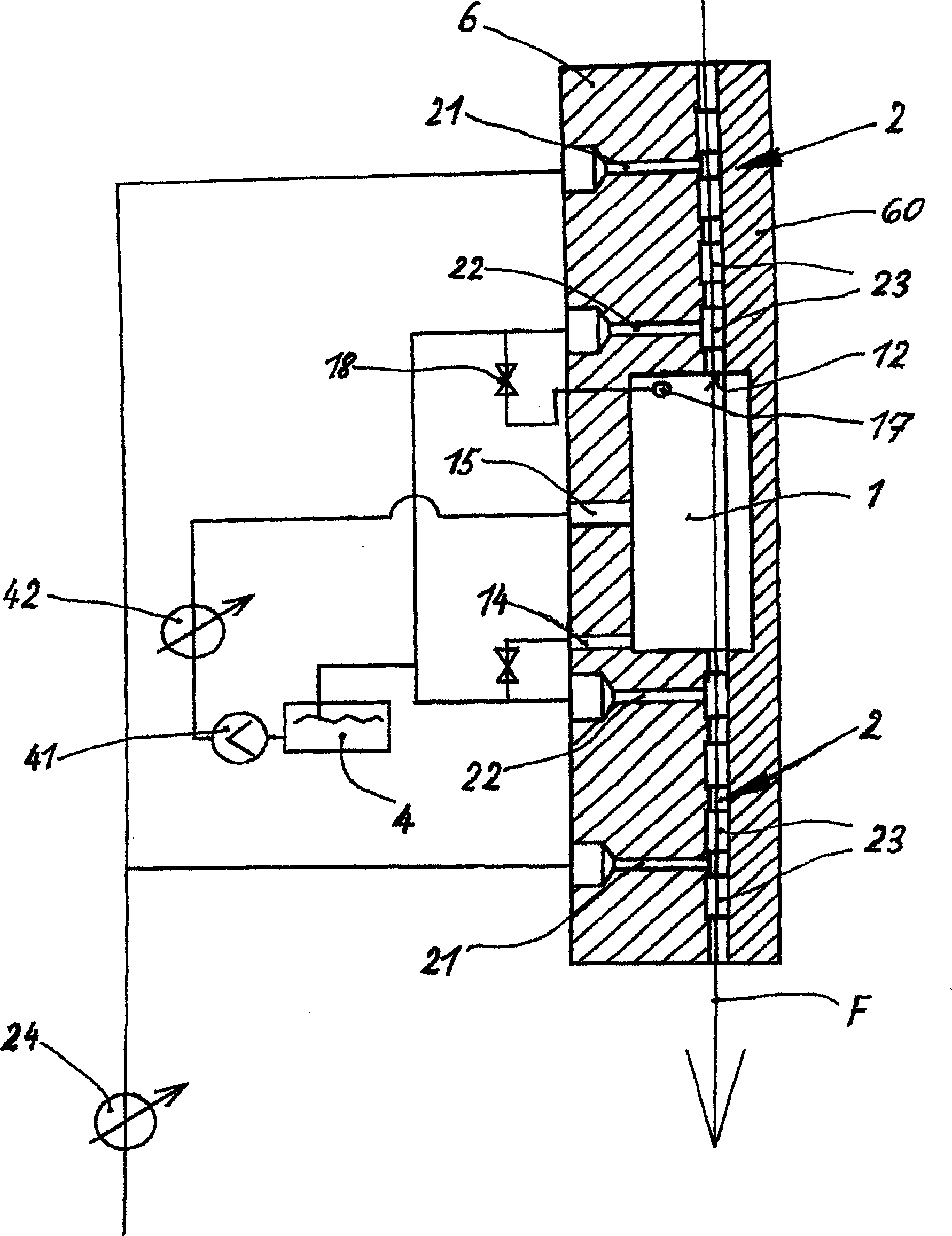

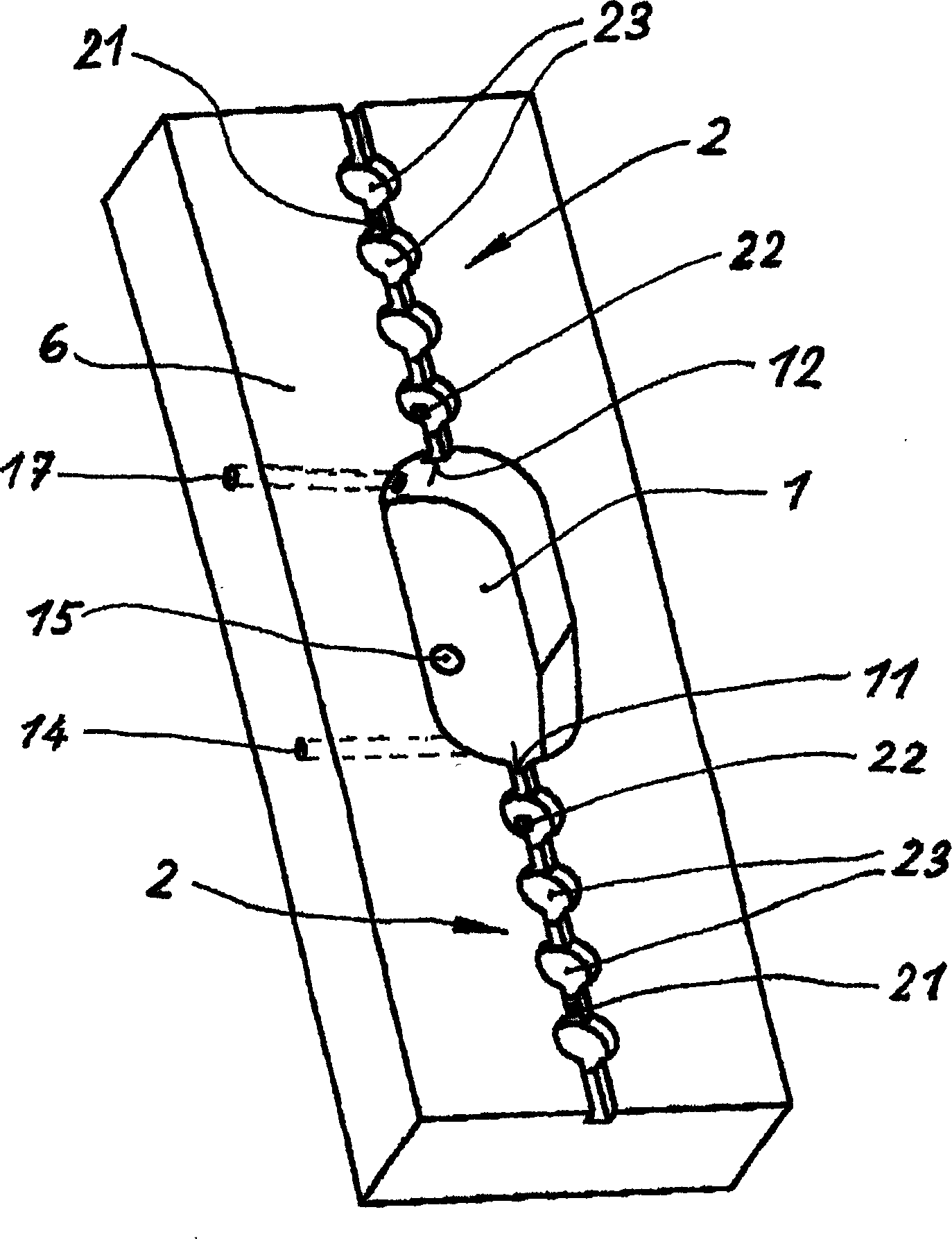

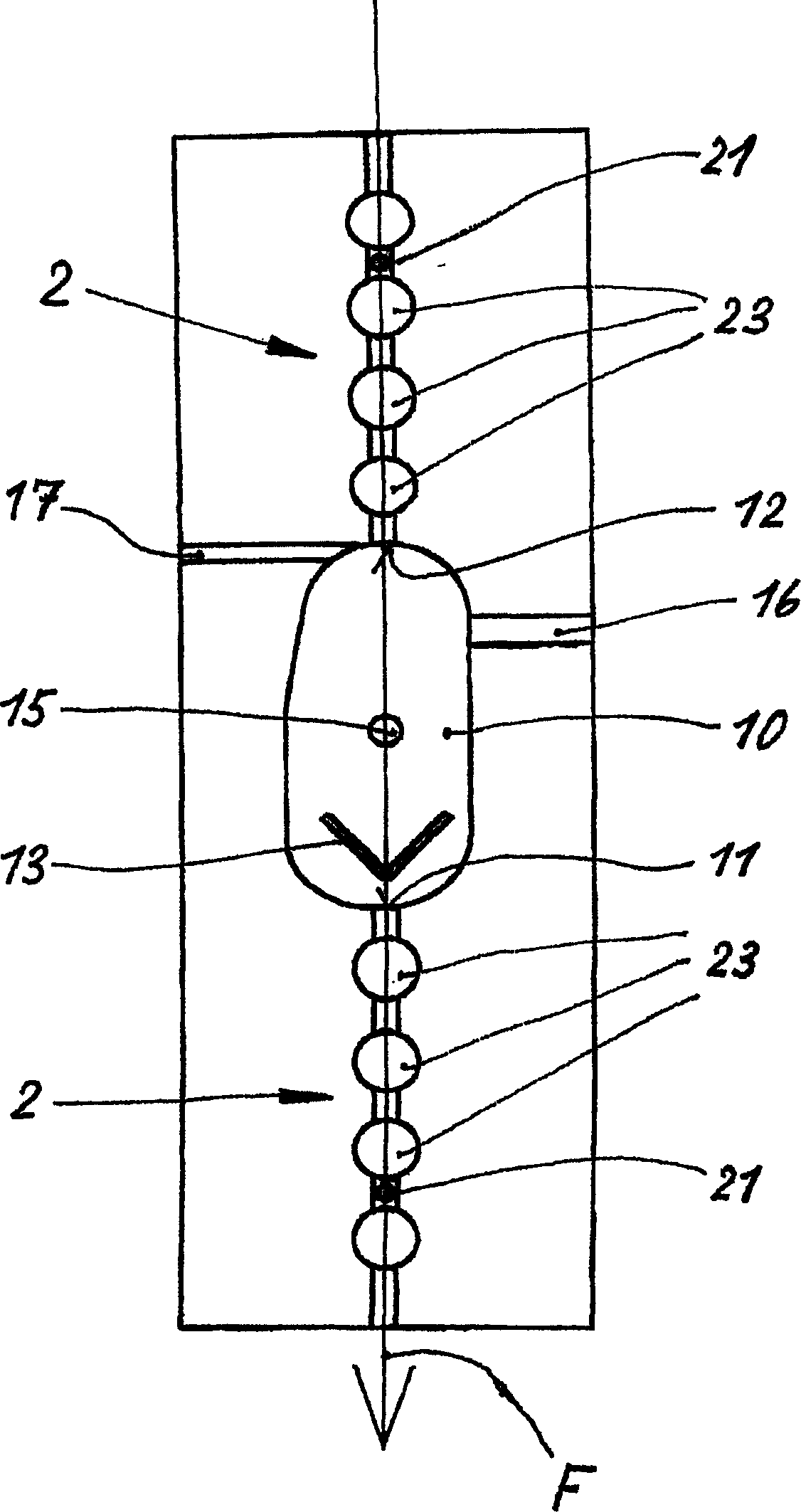

[0052] Embodiments of the invention are described with the aid of a heat exchanger, which is used as a cooler in the texturing process of synthetic yarns, wherein the yarn to be treated passes through it at very high speeds, e.g. at running speeds above 2000 m / min cooler. It requires a high cooling effect, such as cooling the yarn from about 200°C to about 50°C in a short period of time. Water in direct contact with the yarn is used as coolant. The sealing device 2 is filled with air. Of course, other heat exchange media or sealants can also be used for the heat exchanger used in the corresponding process and for the corresponding purpose. The heat exchanger described with the aid of an exemplary embodiment for processing synthetic yarns can also be used without problems for processing textile panels or films.

[0053] figure 1 The heat exchanger shown as a cooler has a base body 6 and a cover plate 60 . The heat exchanger is detachable, that is, the yarn running on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com