Sterilization, bacteriostasis papers as well as manufacturing methods and usage

A manufacturing method and technology of antibacterial paper, applied in the direction of paper and other directions, can solve the problems of large sterilization and odor, only killing existing bacteria, large amount of bactericide, etc., and achieve the effect of preventing drug resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in more detail through specific embodiments below, and the content of specific embodiments does not limit the protection scope of the present invention in any way.

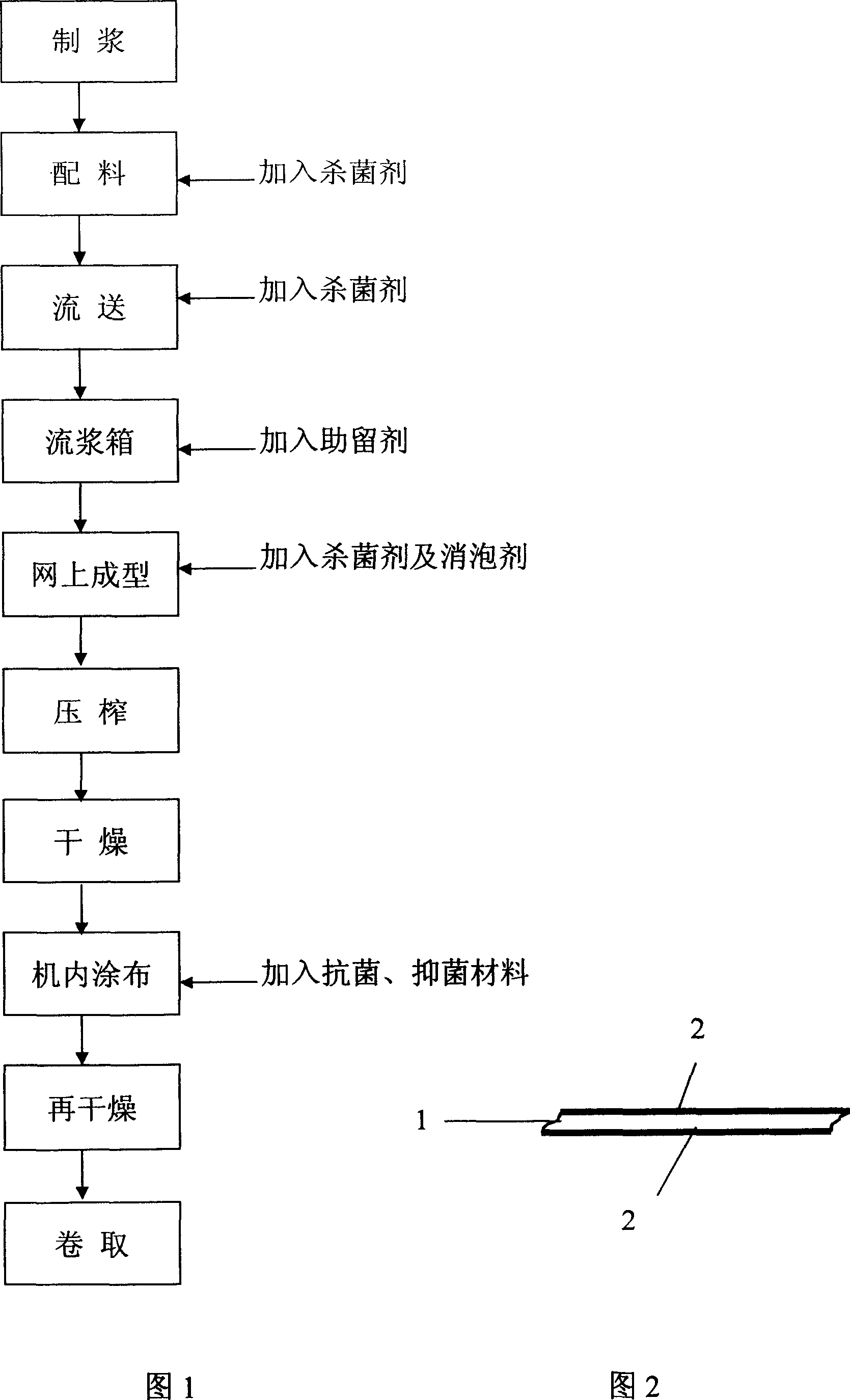

[0018] The papermaking process shown in Figure 1 includes beating, batching, flow delivery, online forming, drying, in-machine coating and re-drying. In the process of batching, flow delivery, and online forming, the ratio of 40 to 120ppm / ton Add fungicides (for absolute dry pulp), take 30-50 days as a cycle, adjust the type and proportion of fungicides once per cycle, add fungicides to white water under the net during online molding; add auxiliary fungicides to the headbox Retention agent.

[0019] The basic components of the above fungicide are isothiazolinone, octylisothiazolinone, non-oxidizing organic bromine, and DMDM caprolactone.

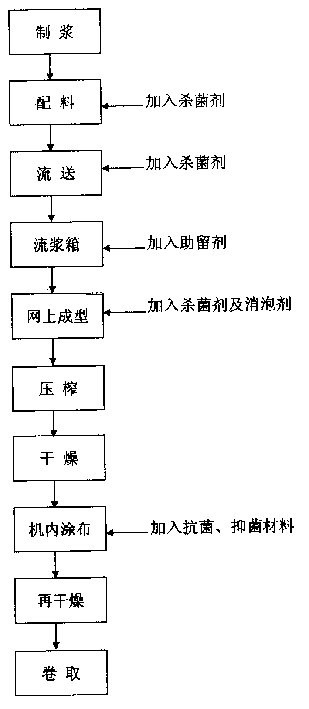

[0020] When coating inside the machine, zinc oxide whisker antibacterial materials are added, based on the effective addition a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com