Pressure sensor and its manufacturing method

A technology of pressure sensor and sensing element, applied in the direction of measuring fluid pressure, measuring fluid pressure through electromagnetic elements, instruments, etc., can solve the problems of connector part size and shape limitation, difficulty, increase capacitor installation area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

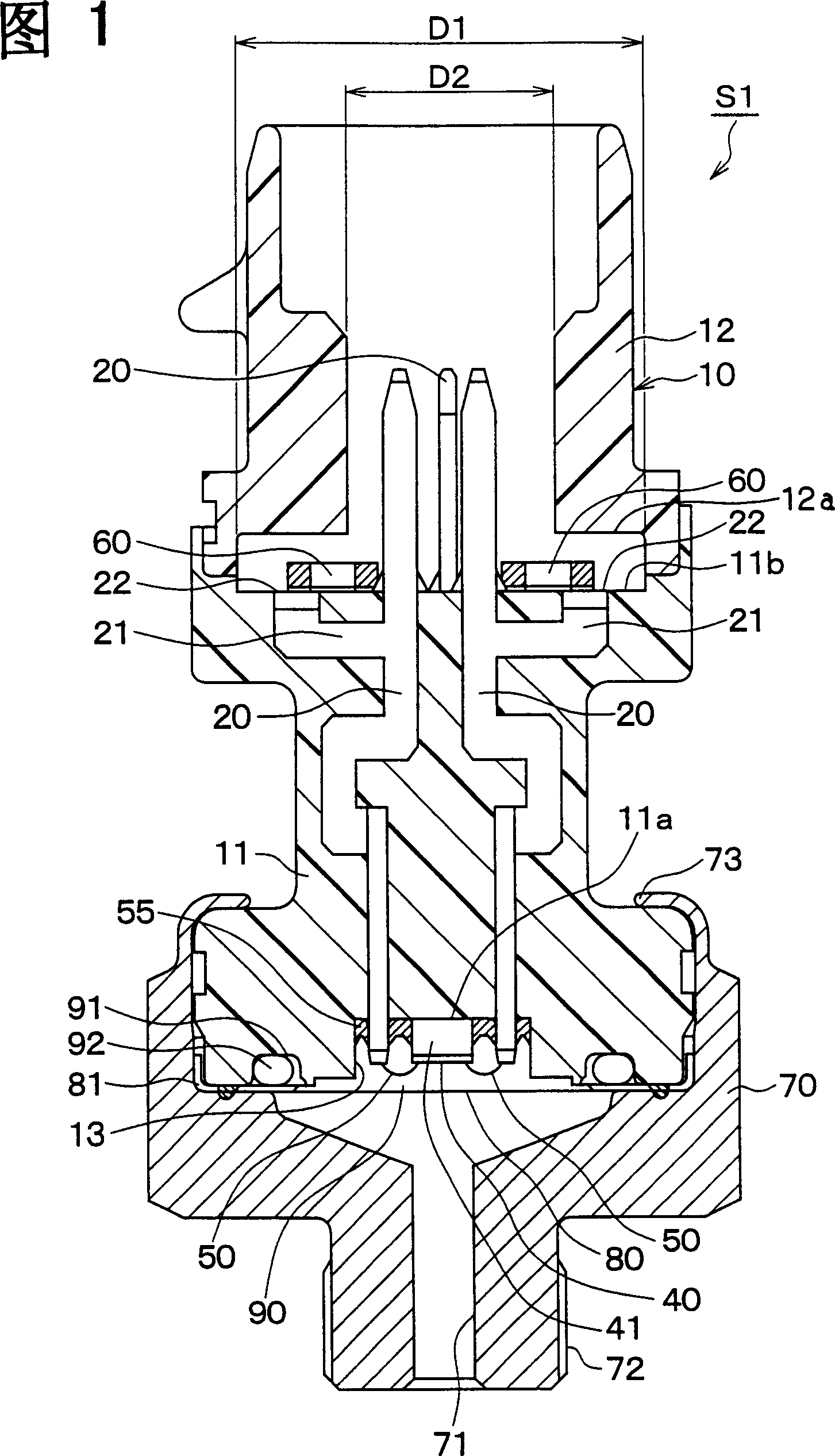

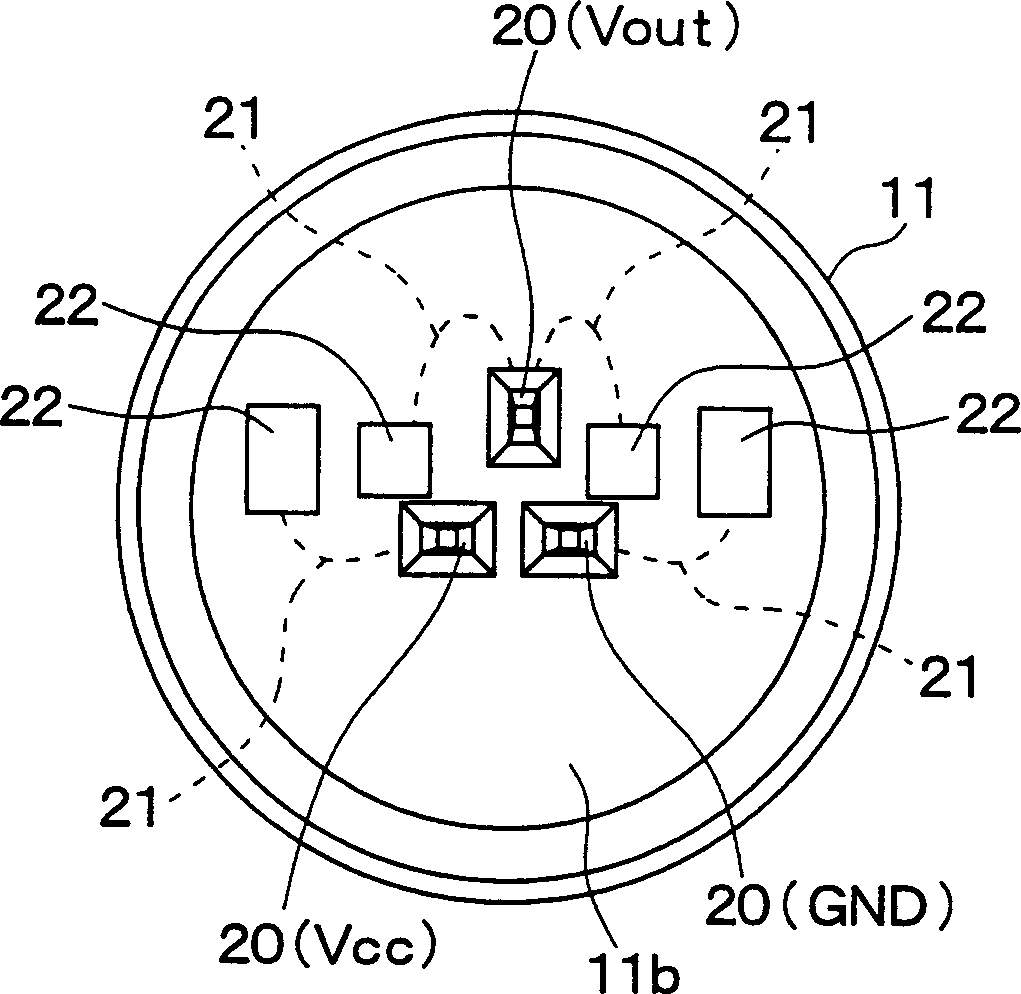

[0022] Preferred embodiments of the present invention will now be described with reference to the accompanying drawings. In this preferred embodiment, the pressure sensor S1 shown in FIG. 1 is generally used to detect the refrigerant pressure in an air conditioner installed in, for example, a vehicle.

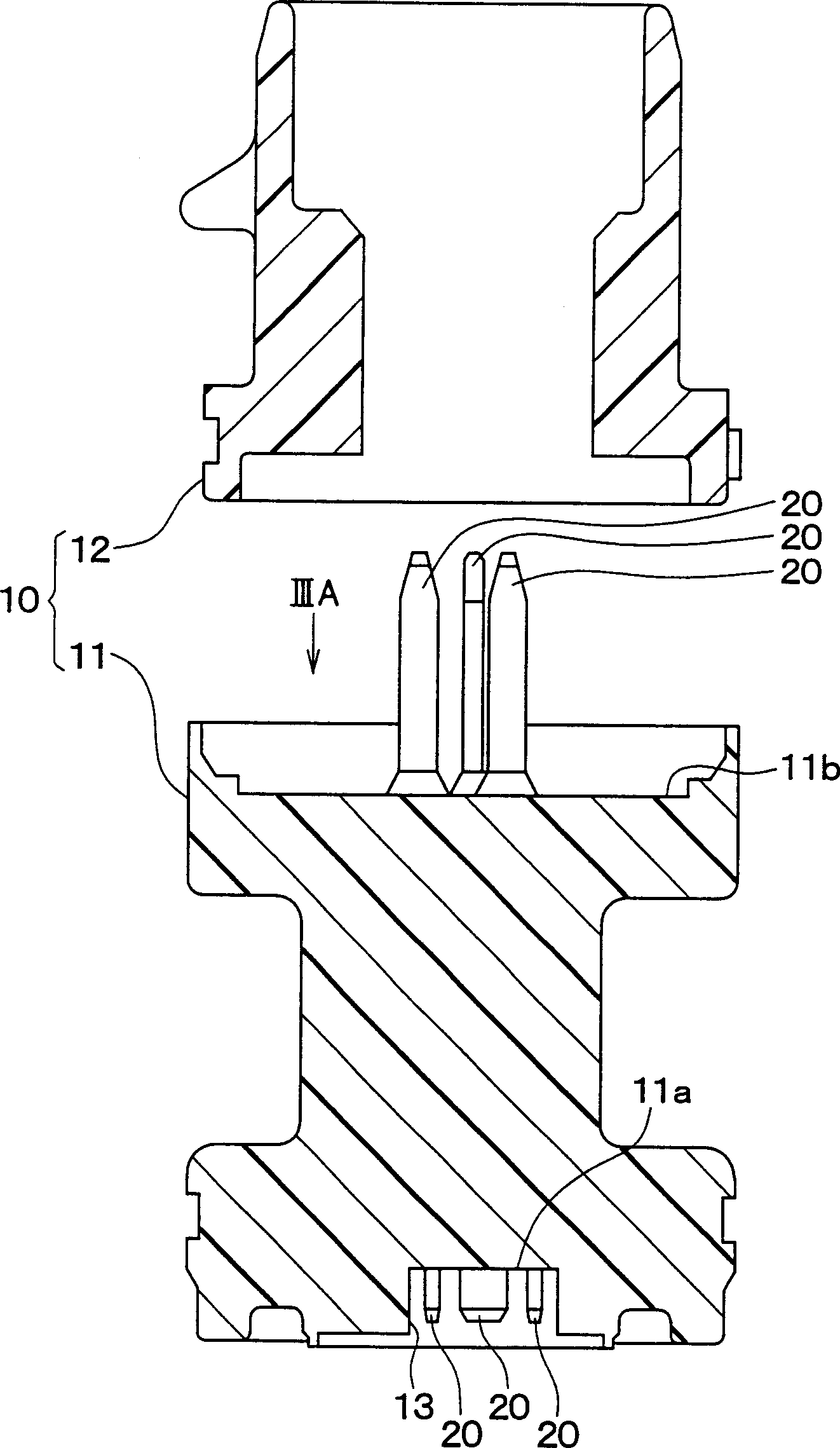

[0023] Pressure sensor S1 contains figure 2 The housing part 10 is shown. figure 2 Shown is the case when the housing part 10 is separated, and the housing part is now divided into a first housing 11 and a second housing 12 . As shown in FIGS. 1 and 2 , the case member 10 is constructed by assembling a first case 11 and a second case 12 together. Both the first case 11 and the second case 12 are integrally molded by one-step molding using a resin such as polyphenylene sulfide (PPS) or polybutylene terephthalate (PBT).

[0024] The first housing 11 is shaped into an approximately cylindrical shape with a stepped portion. A groove portion 13 is formed in one end of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com