Oscillator with voltage control

A voltage-controlled oscillation and voltage-controlled technology, applied in power oscillators, electrical components, impedance networks, etc., can solve the problems of voltage-controlled oscillator Q-value drop, poor stability, and large changes in reactive components over time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

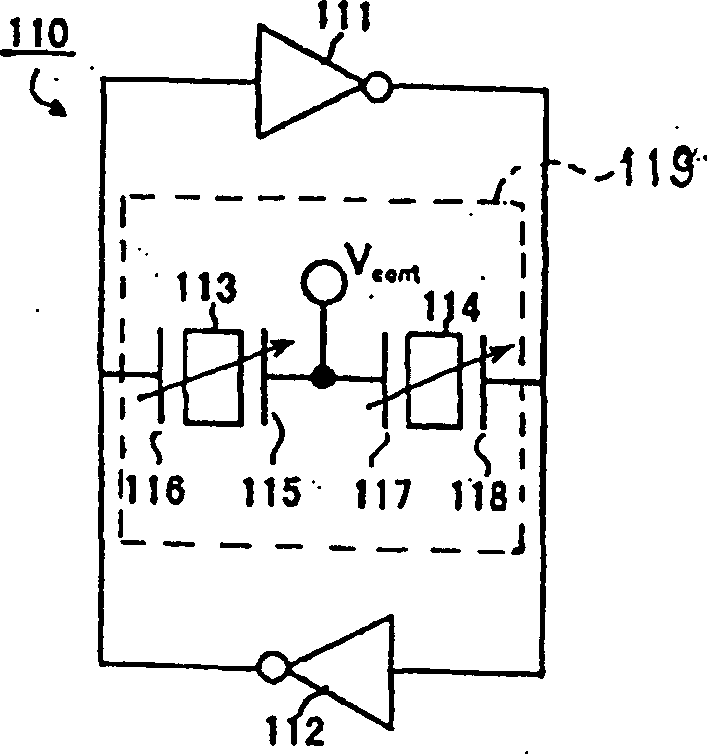

[0063] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. The present invention is not limited to the following embodiments, and various modifications are possible.

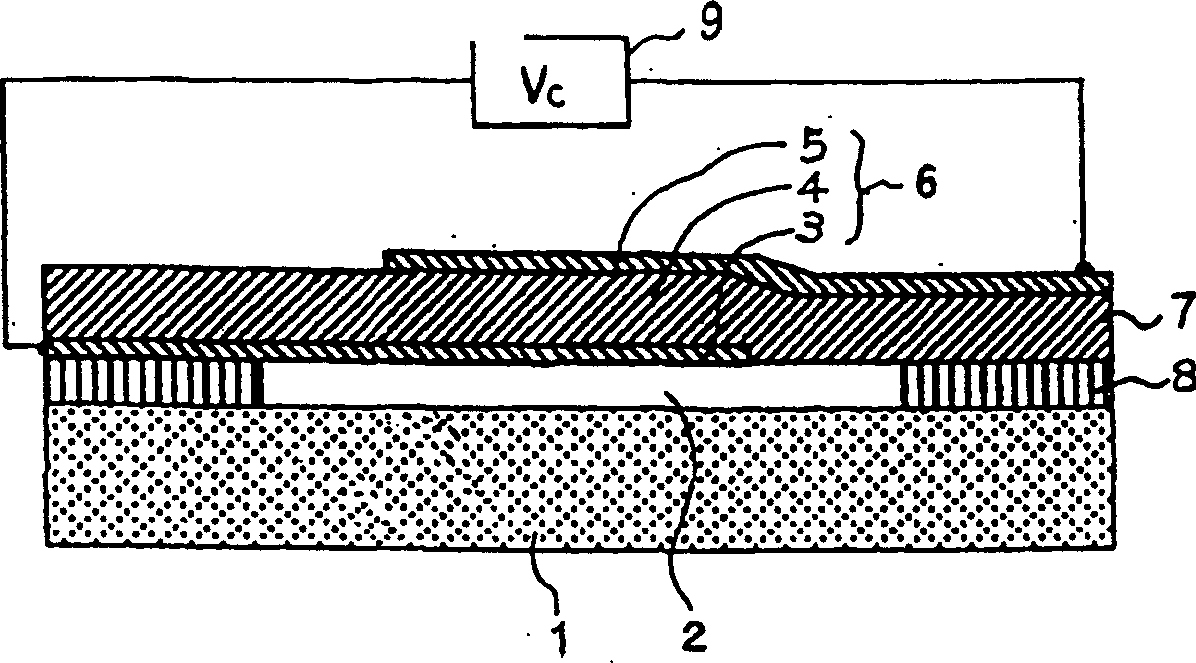

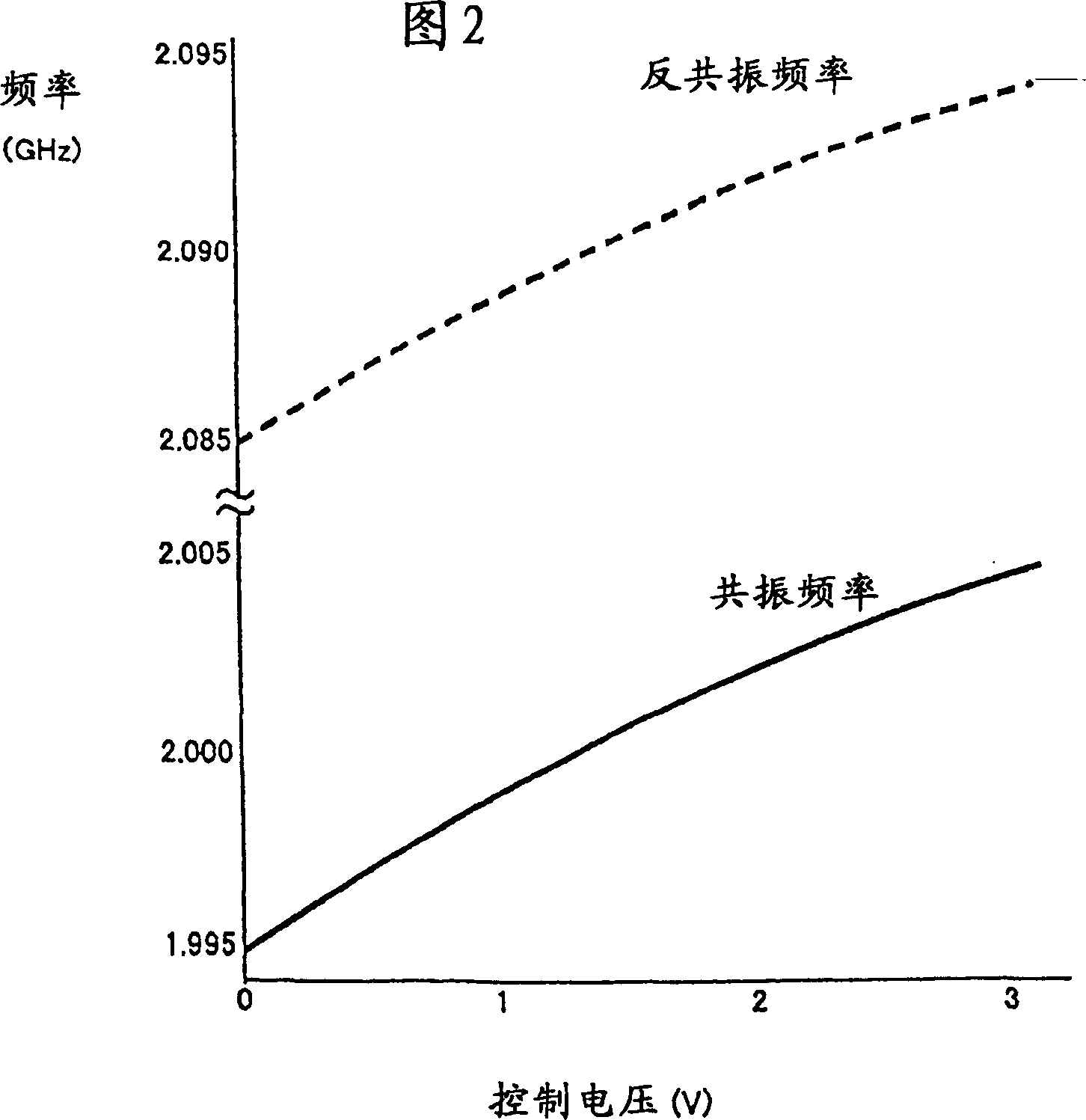

[0064] The inventors of the present invention repeatedly discussed the use of a piezoelectric body using a ferroelectric body as a thin-film piezoelectric resonator from a wide range of theory and experiment. It was found that the ferroelectric material essentially has the property that the speed of sound can be greatly changed by an external electric field. By satisfying several conditions and applying a control voltage to the ferroelectric, the oscillation frequency can be changed.

[0065] Specifically, a ferroelectric material used as a piezoelectric body needs to be a single crystal film whose polarization direction is uniform in the film thickness direction. In order to obtain sufficient piezoelectricity of the ferroelectric film and to change the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com