Dispatching component for associating mfg. facility service requestors with service providers

A technology for service requests and manufacturing equipment, which is applied in the direction of control/adjustment system, program control, computer control, etc., can solve the problems of reducing the wafer processing output of processing equipment, unscheduled maintenance or downtime process interruption, etc., to improve efficiency and productivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

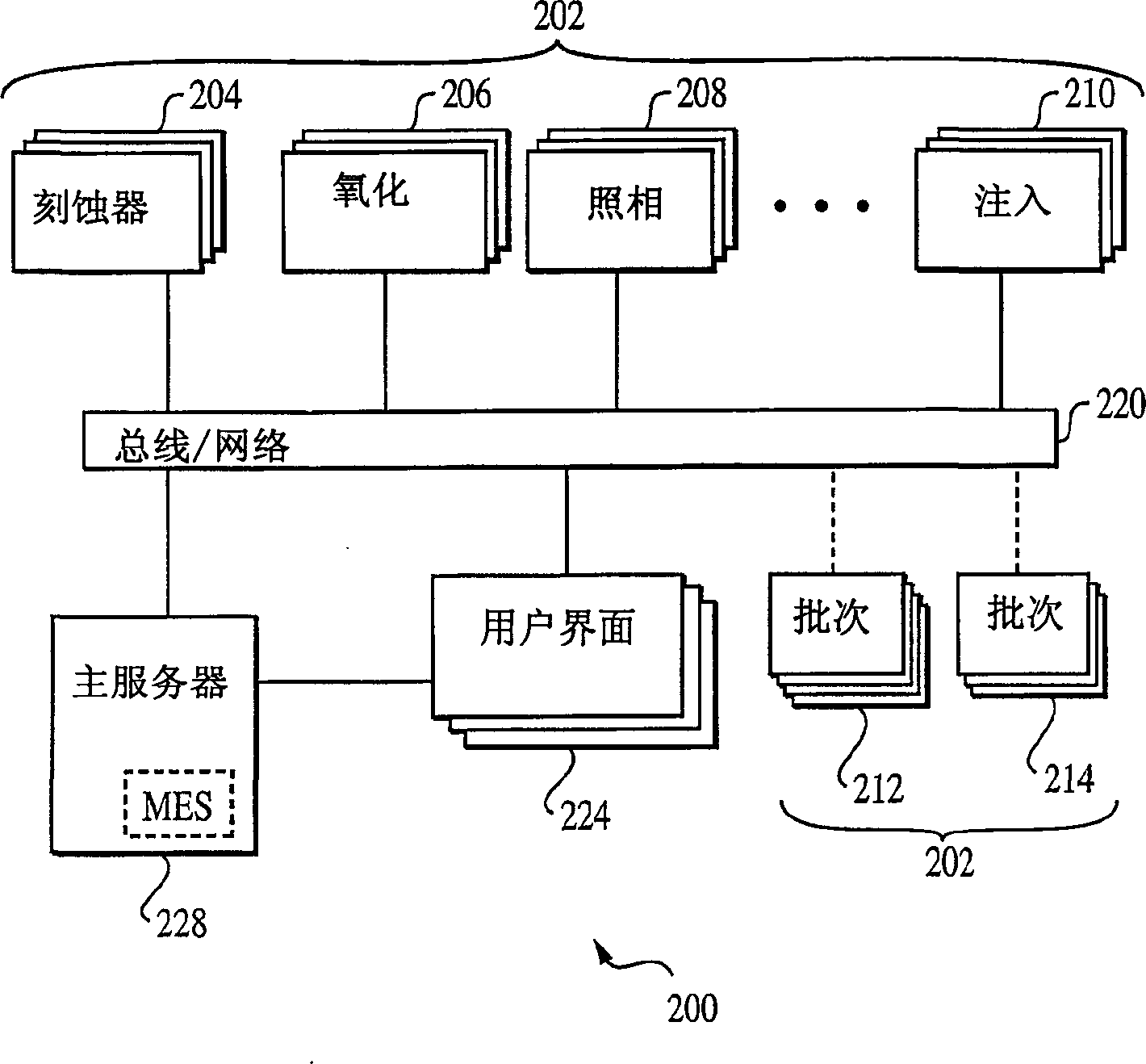

[0022] figure 2 An example of manufacturing equipment suitable for implementing and utilizing the principles of the invention is shown. now refer to figure 2 An automated semiconductor fabrication facility 200 is described for use in the fabrication of semiconductor devices by executing one or more fabrication service plans. The device 200 includes a number of resource nodes 202 each connected to another node by means of a data bus 220 , a number of user interfaces 224 and a computing master server 228 . Each resource node 202 (ie, a service provider or service requester as described below) is associated with a manufacturing facility 200 for monitoring resources. In the contemplated embodiments of the present invention, resource nodes 202 perform tasks by computer programs or computing servers residing in or connected to their respective resources. For example, a resource node includes hardware or software that can perform tasks, eg, in a computing processor at the resour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com