Bacteria-free isolated operation system

A technology of operating system and sterilization system, applied in the field of aseptic operation devices, can solve the problems of inability to operate aseptically, the flame sterilization aseptic connector is complicated in structure, cannot be sterilized, etc., and achieves the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

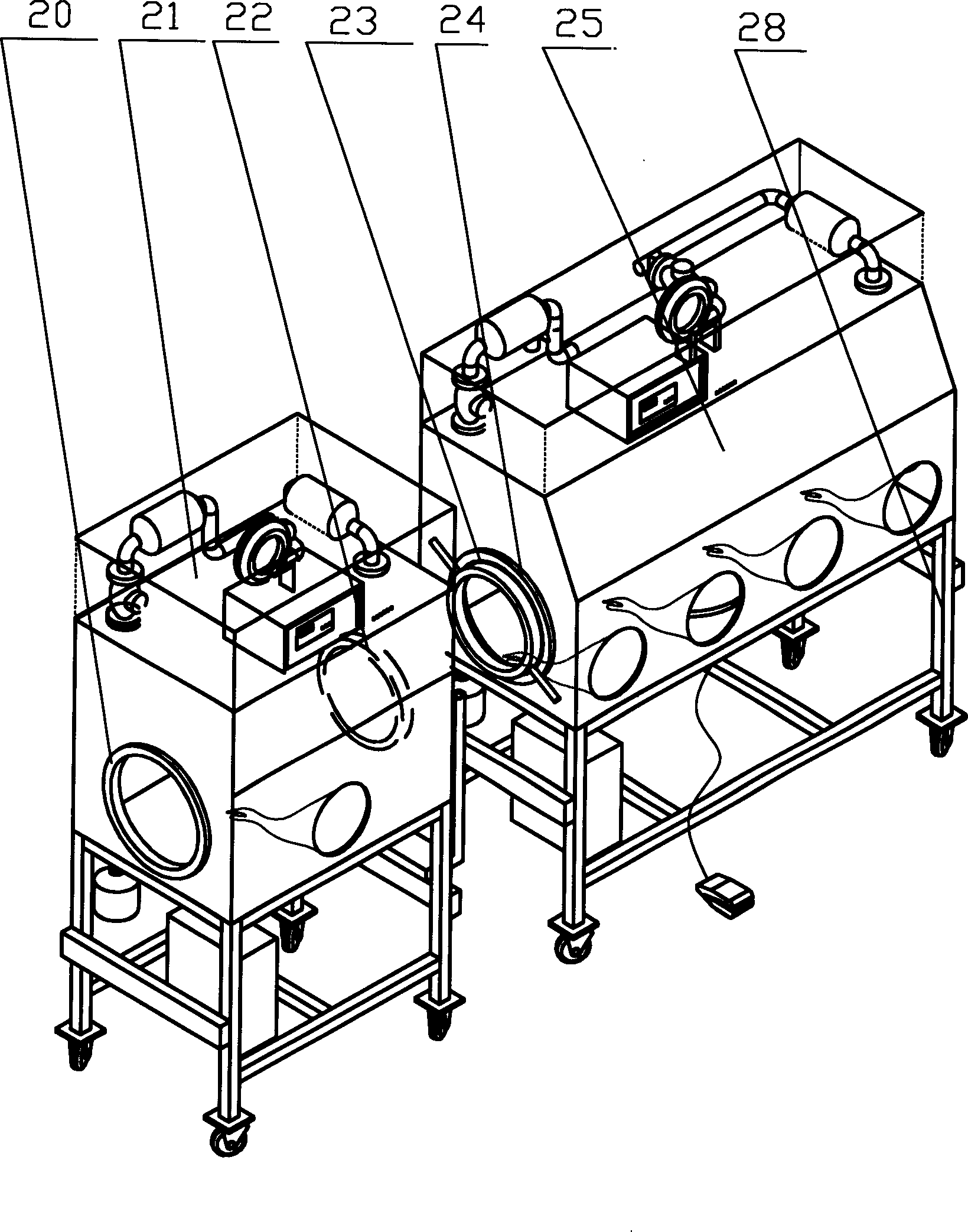

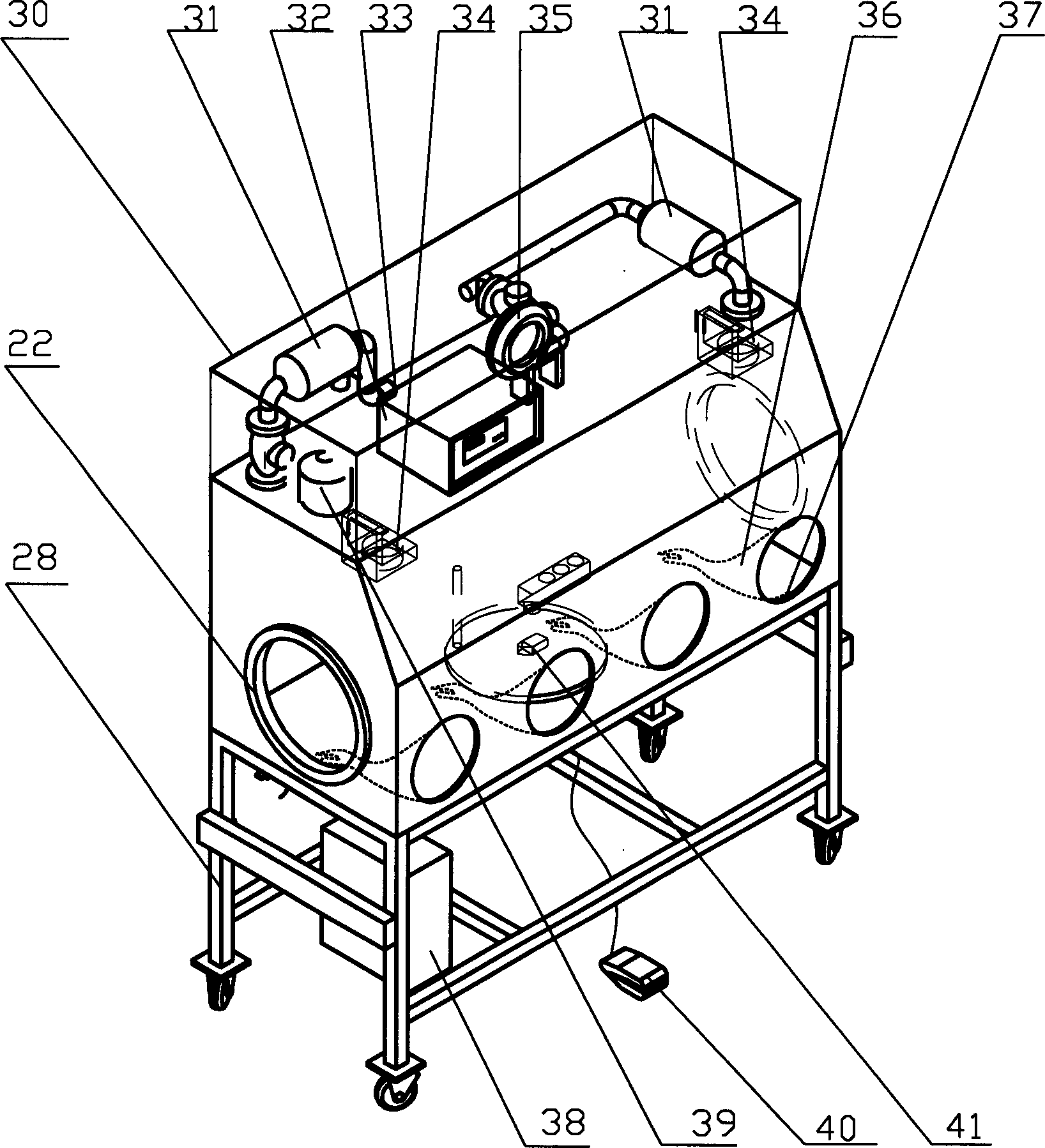

[0018] Such as figure 1 , 2 , the basic composition of the aseptic isolation operating system can be made up of two aseptic cabins, namely the aseptic transfer cabin 21 and the sterile experiment cabin 25. It can also be composed of a sterile transfer cabin 21 and several sterile experiment cabins 25 as required. Sterile chamber 21 and aseptic experiment chamber 25 are placed on the mobile support 28, and described aseptic chamber 21,25 is made of transparent material, has several sealed glove holes 26 and operating gloves 25 on the cabin; Simply reach into the cabin to operate.

[0019] The sterilization system on the aseptic cabin can be made up of ozone generator 33, ultrasonic nebulizer 39 and fan 34, also can be made up of sterilant atomizing device. Air circulation system is made up of blower fan 35, air filter 31;

[0020] The upper part of the aseptic cabin has a top cover 30 to ensure the cleanliness of the equipment.

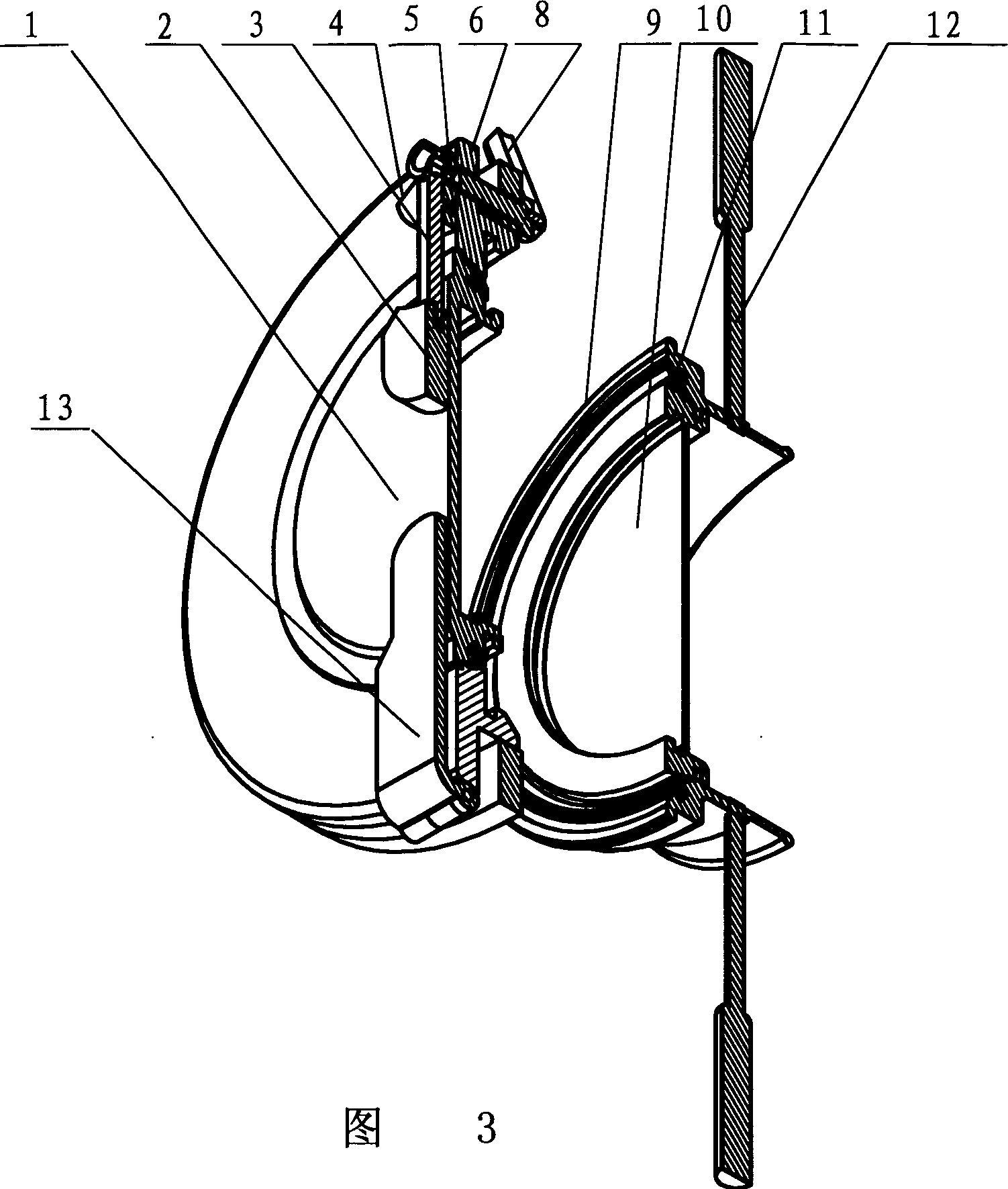

[0021] The two ends of the sterile transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com