Micropole diffusor of rotary compressor

A rotary compressor and silencer technology, applied in the field of compressors, can solve the problems of poor noise reduction effect and poor noise reduction effect, and achieve the effect of reducing intensity and attenuating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

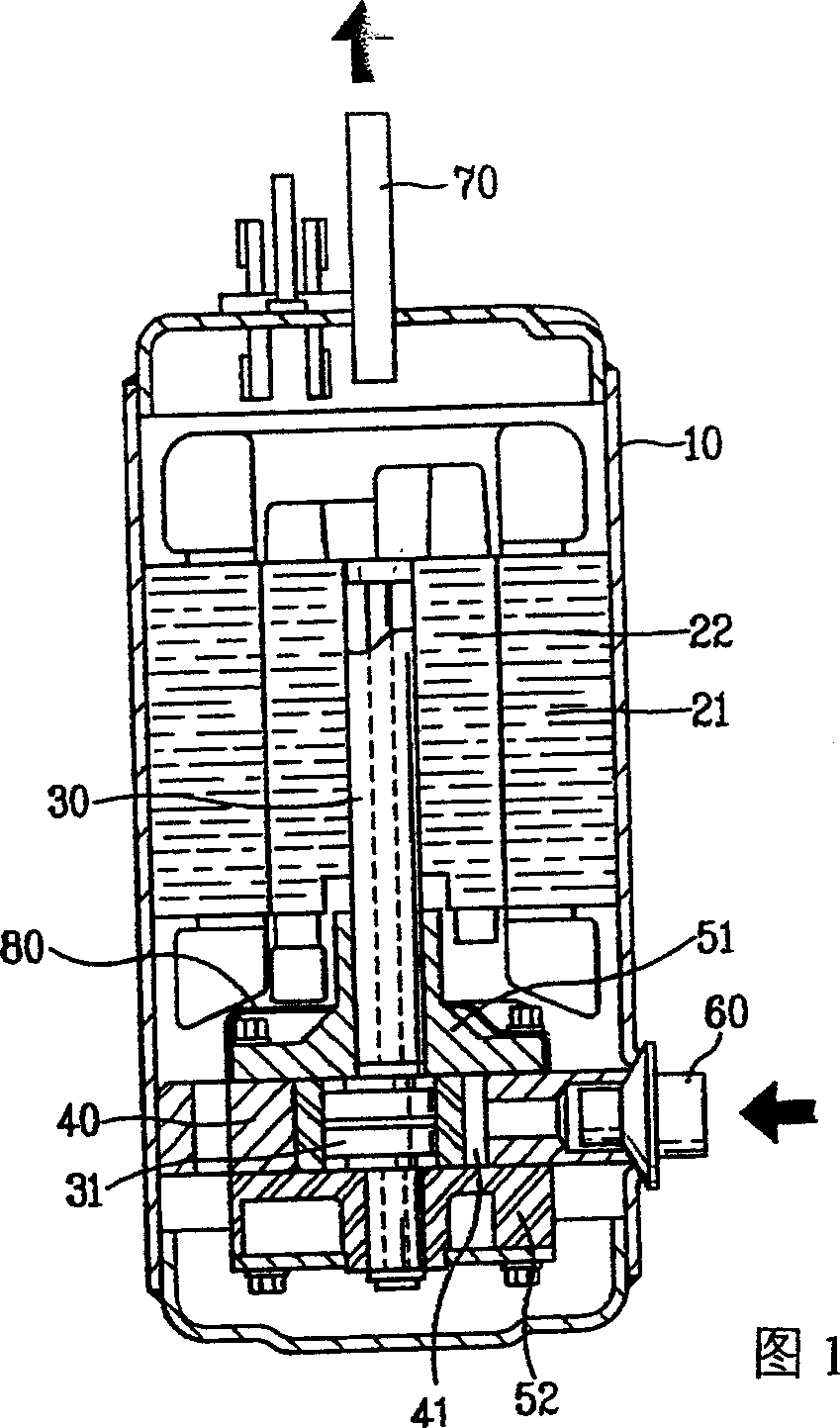

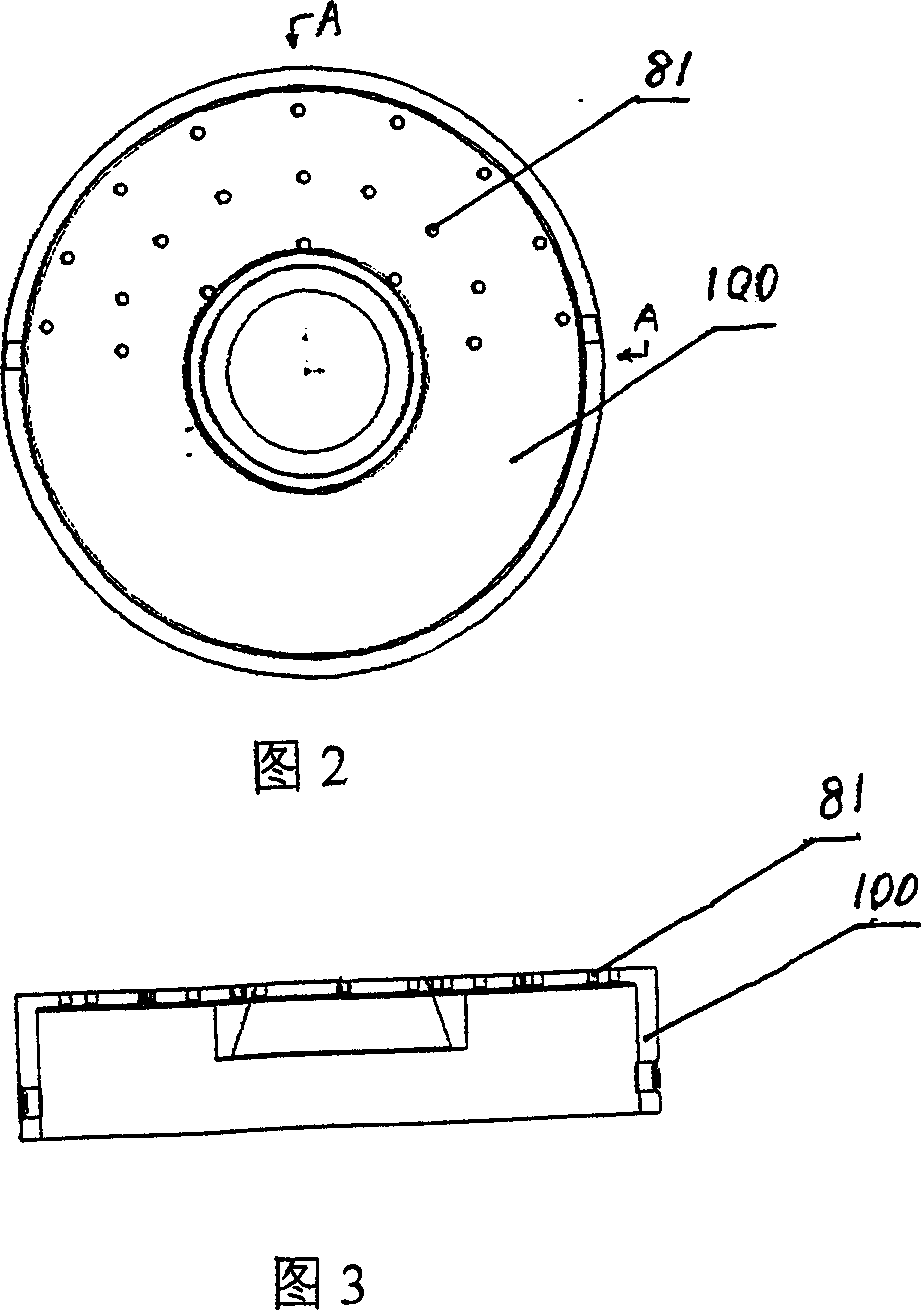

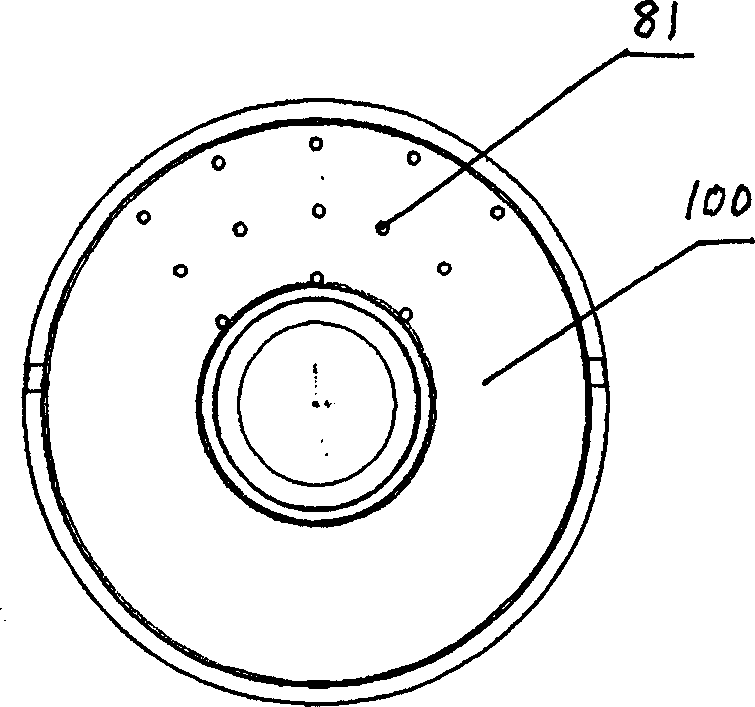

[0017] The structure of the compressor of the present invention is as shown in Figure 1: the rotary compressor has a closed casing 10, the stator 21 and the rotor 22 of the rotary compressor motor are installed on the top of the casing 10, and the eccentric shaft 30 is fixed in the middle of the rotor 22, The cylinder block 40 of the compressor is located at the bottom of the airtight casing 10, and the eccentric shaft section 31 of the eccentric shaft 30 is arranged in the cylindrical cylinder hole at the center of the cylinder block 40, and the outer cylindrical surface of the eccentric shaft section 31 has a rolling rotor, and the eccentric shaft section 31 When the eccentric shaft 30 rotates in a circular motion in the cylinder bore, the rolling rotor compresses the gaseous refrigerant entering the cylinder block 40. There is also a baffle (not shown in the figure) separating the refrigerant in the high and low pressure areas in the cylinder block. The upper and lower end s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com