Substrate treating device

A substrate processing device and substrate technology, applied in lighting and heating equipment, cleaning methods and utensils, drying, etc., can solve problems such as island-shaped residual liquid that is easy to generate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in more detail below with reference to the accompanying drawings.

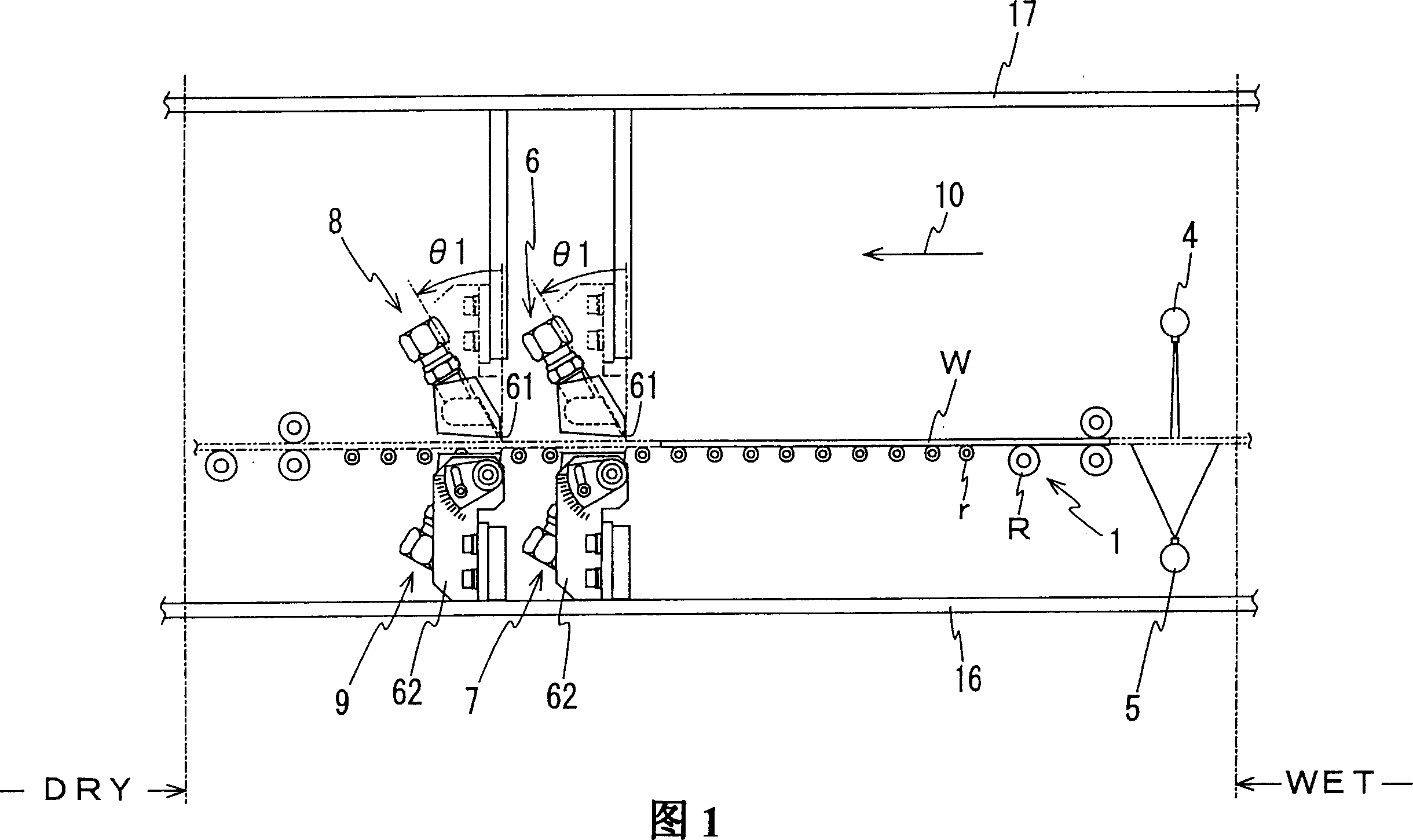

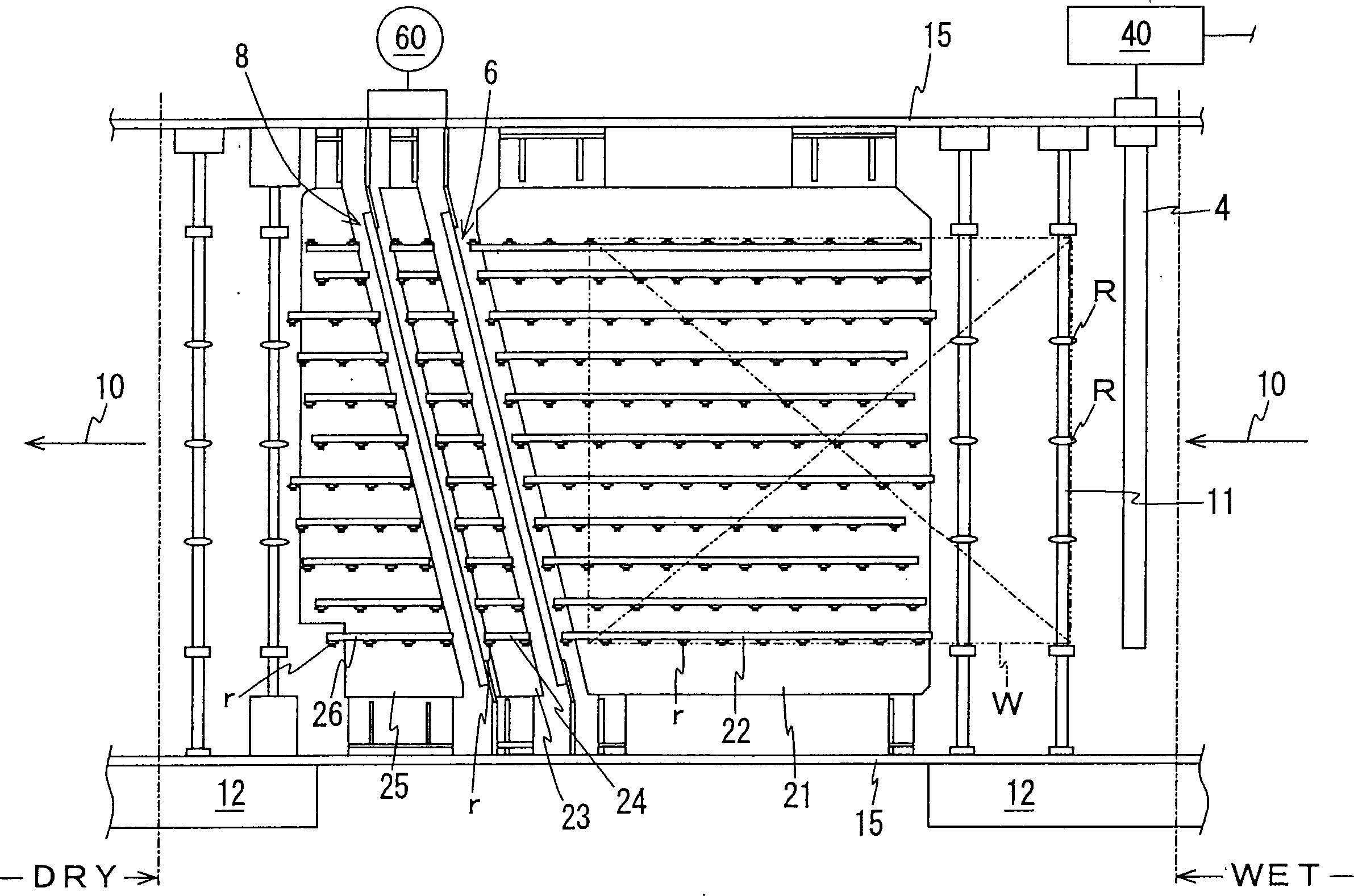

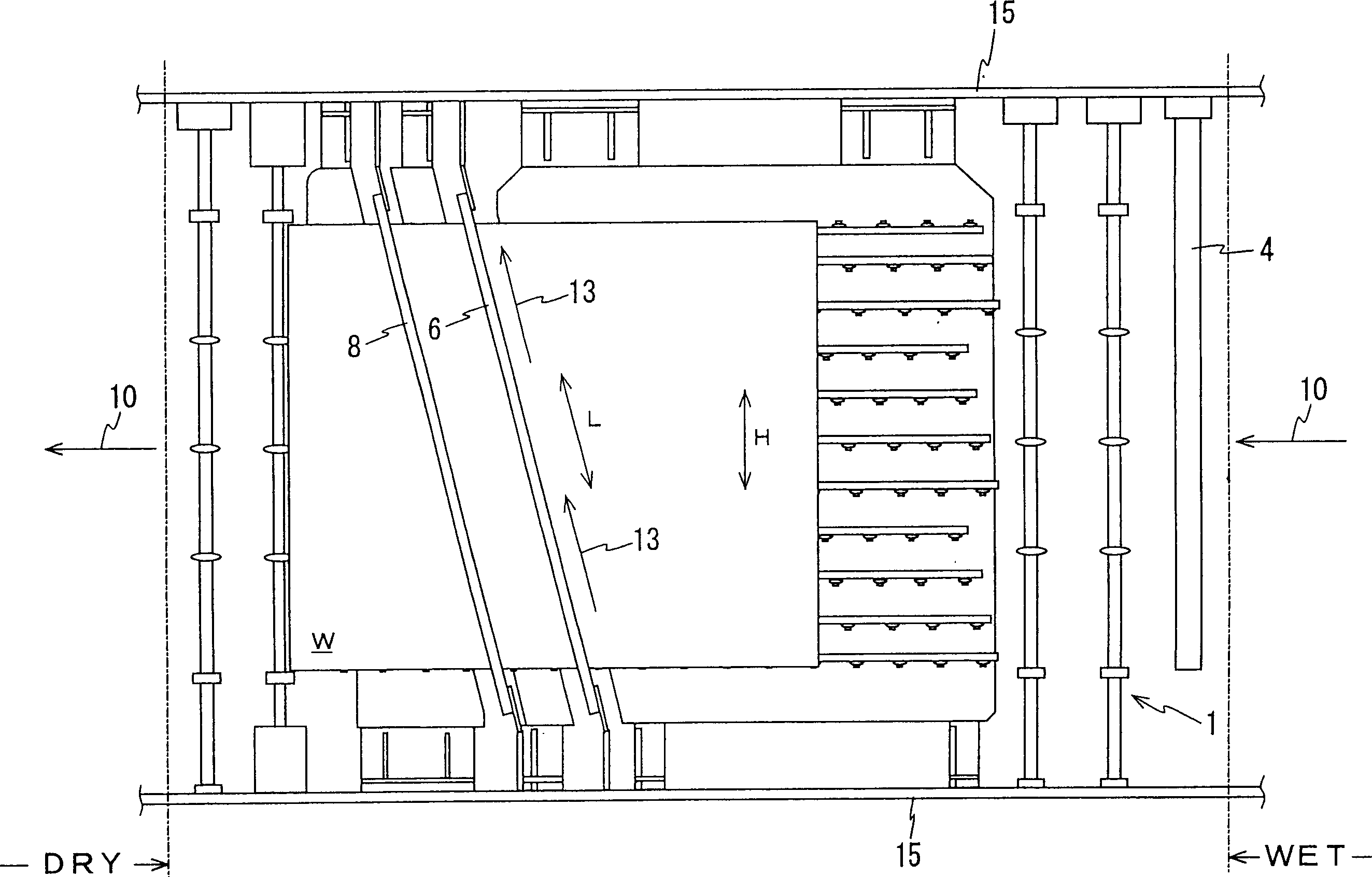

[0027] As shown in FIG. 1 , the substrate processing apparatus of the present invention includes: a transport mechanism 1 that horizontally transports a substrate W in the direction of an arrow 10; a wet processing unit WET that performs a wet process on a substrate W transported by the transport mechanism 1; The dry processing part DRY of dry processing; and the membrane liquid supply mechanism 4, the first upper air knife (air knife) 6, the first lower air knife 7, The second upper air knife 8, the second lower air knife 9.

[0028] Also, the above-mentioned wet processing part WET, membrane liquid supply mechanism 4, the first upper air knife 6, the first lower air knife 7, the second upper air knife 8, the second lower air knife 9 and the dry processing part DRY are storage In the cover body that is made of 2 sidewalls 15,15, base plate 17, upper plate 17. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com