Hydromechanical speed-change device and vehicle having speed change device mounted thereon

A speed change device, mechanical technology, applied in motor vehicles, mechanical equipment, power units, etc., can solve the problems of working oil deterioration, difficult working oil characteristics, mixed with oil residues, etc., and achieves easy cooling, improved maintenance, and improved maintenance. Effects of degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

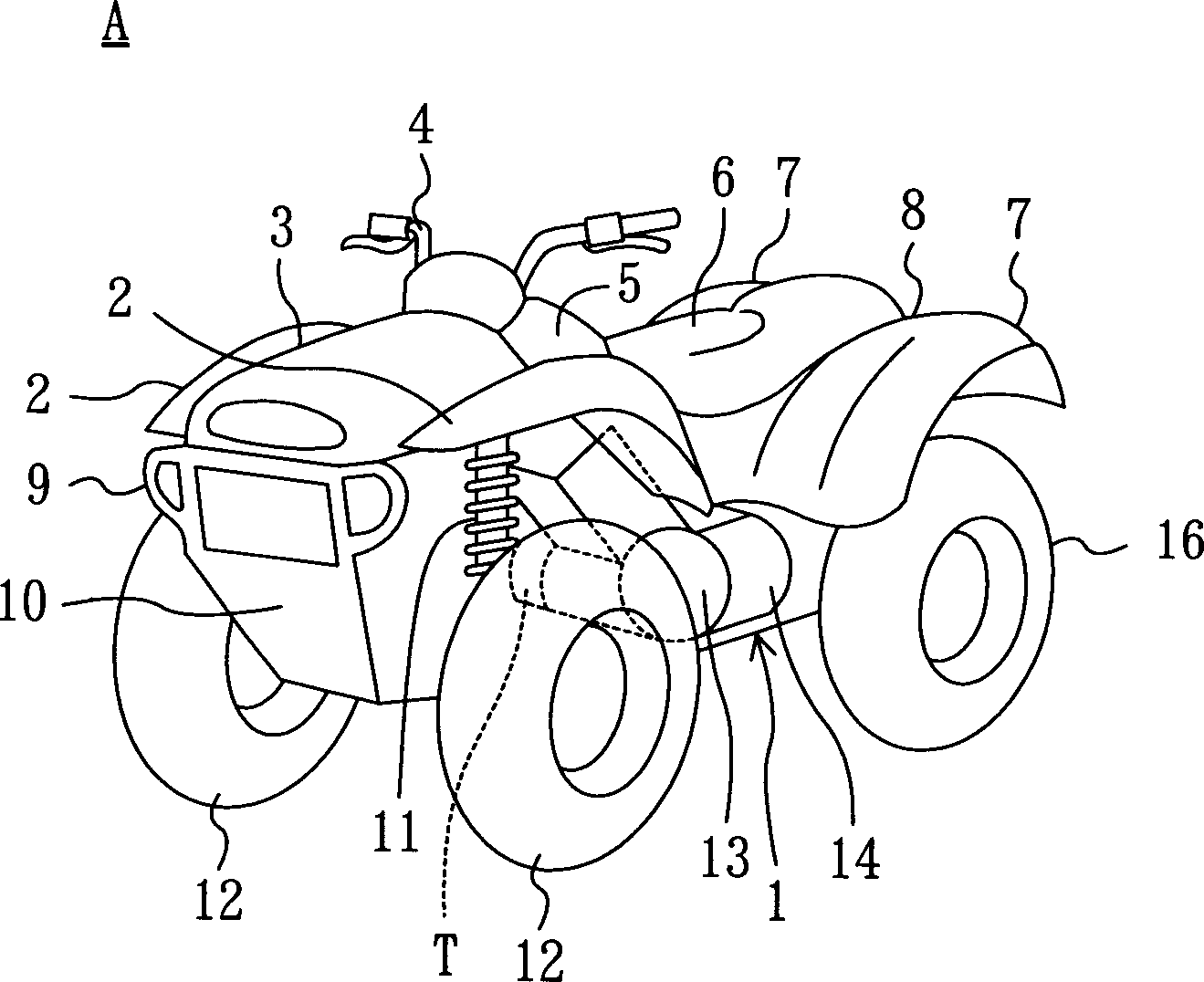

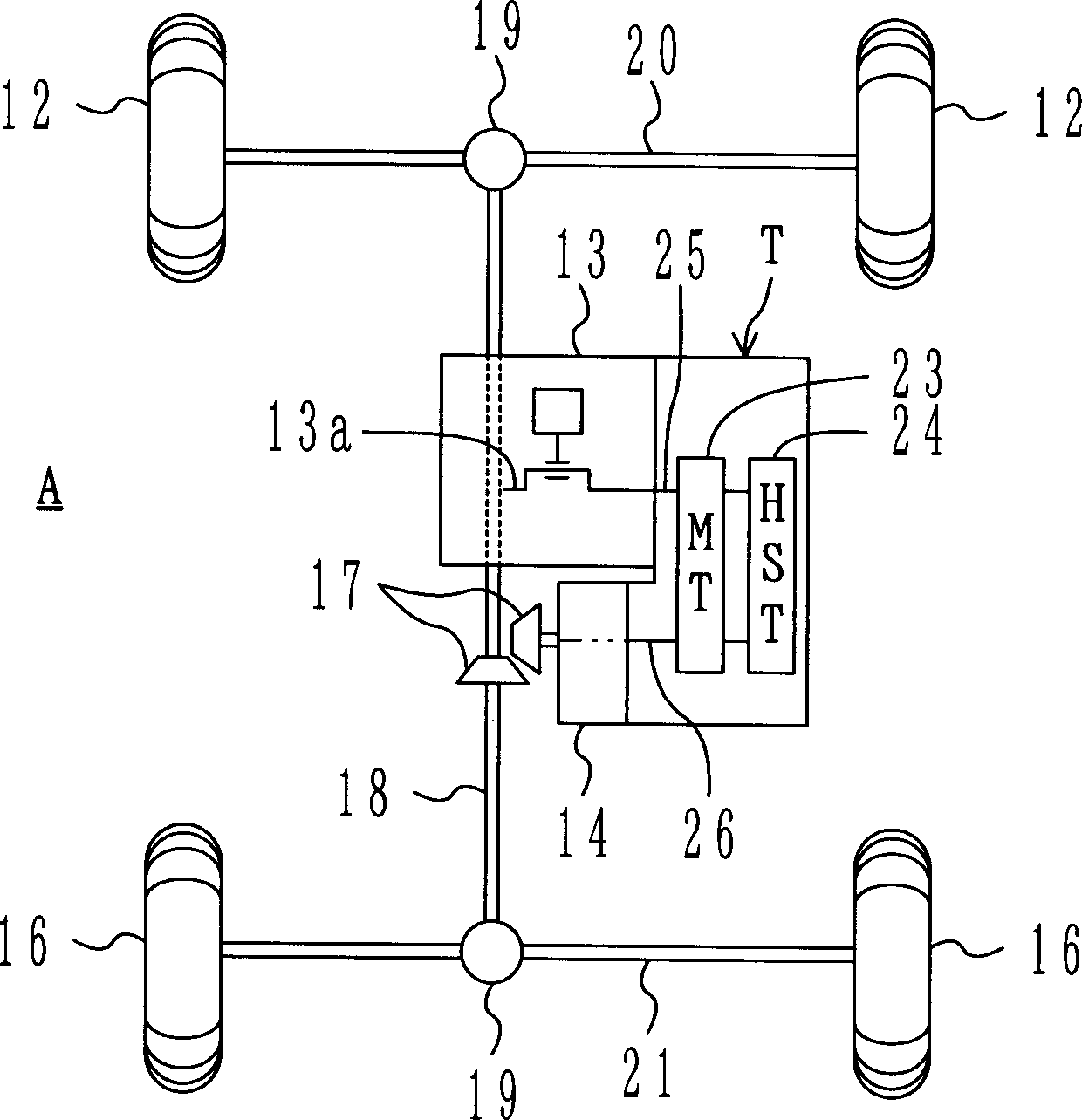

[0041] Embodiment 1 of the present invention will be described in detail below with reference to the accompanying drawings. This embodiment is a 4-wheel drive all-terrain vehicle (A) equipped with a hydromechanical transmission (HMT) (T) according to the present invention. figure 1 Indicates the appearance of the all-terrain vehicle (A), and the symbol (1) is a chassis with details omitted. On the top of this car body chassis (1), the front engine cover (3) that is provided with front left and right fenders (2), (2) is arranged from front to back, steering handle (4), fuel tank (5), Chair (driver's seat) (6), and rear engine cover (8) that is provided with rear left and right fenders (7), (7).

[0042] A lower engine cover (10) integrated with a bumper (9) is provided at the frontmost part of the car body below the above-mentioned front engine cover (3), and the front wheels connected by suspension front shock absorbers (11) are arranged on the left and right sides behind it....

Embodiment 2

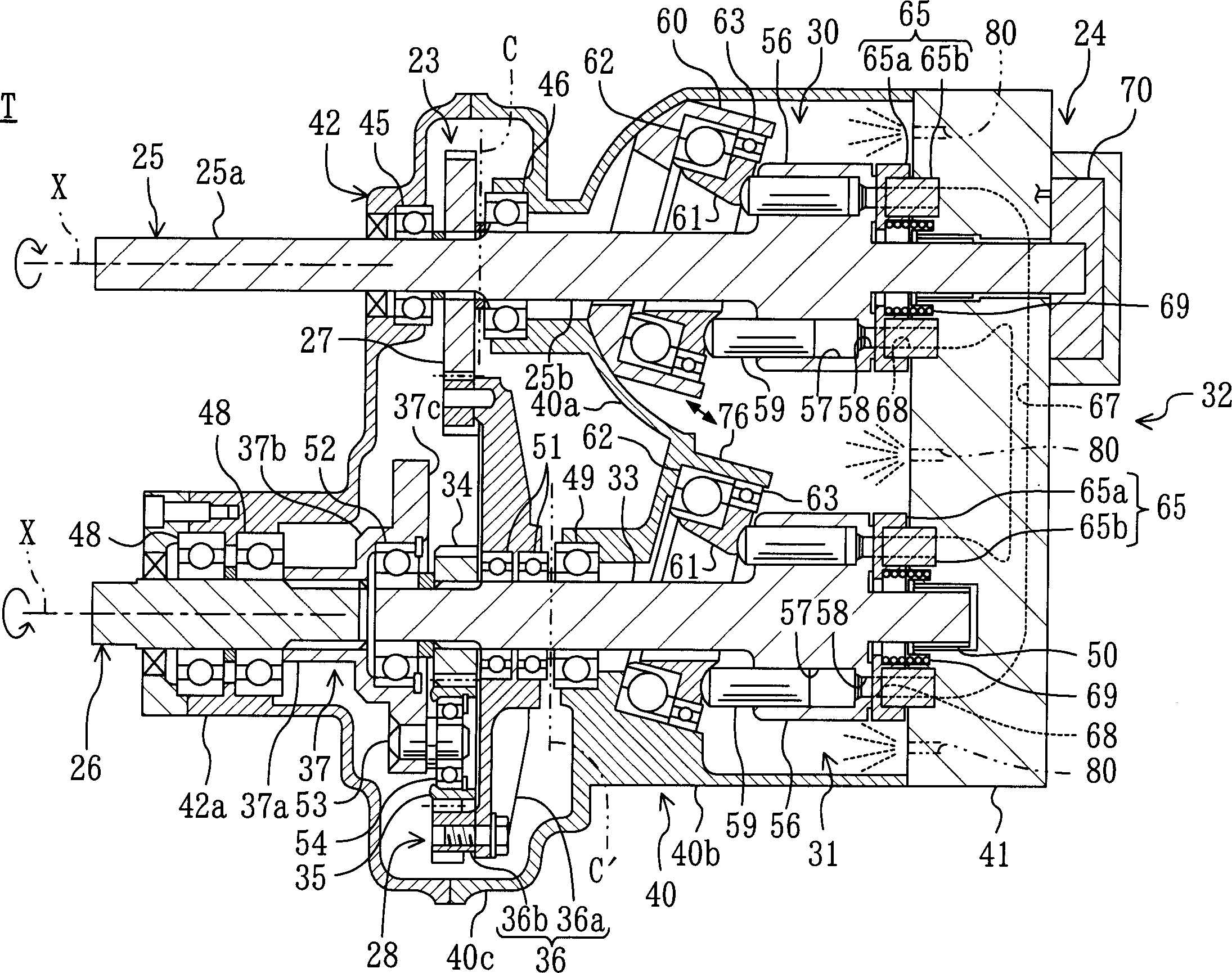

[0071] Figure 5 The structure of the power transmission system of the all-terrain vehicle (A) equipped with the hydromechanical transmission (T) concerning the 2nd Embodiment of this invention is shown. In this embodiment 2, the casing of the hydromechanical transmission (T) is divided into two parts, the hydrostatic transmission casing and the mechanical transmission casing. Except for this point, the hydromechanical transmission of embodiment 2 The structure of the device (T) is the same as that of the above-mentioned first embodiment, therefore, the same components are marked with the same symbols and descriptions are omitted. And, as shown in the figure, the casing of the hydromechanical transmission (T) in Embodiment 2 can be divided into a mechanical transmission casing (80) for accommodating a mechanical transmission (23) and a casing for accommodating a hydrostatic transmission. The hydrostatic transmission case (81) of the device (24), wherein the mechanical transmi...

Embodiment 3

[0076] Figure 7 A hydromechanical transmission (T) according to Embodiment 3 of the present invention is shown. What this embodiment 3 describes is that, as the piston pump (30) and the motor (31) of the hydromechanical speed change device (T), the pump shaft part (25b) of the cylinder barrel (56) and the input shaft (25) , motor shaft (33) are separately made separately, intermesh by spline shaft. At the same time, the input gear (27) of the mechanical transmission (23) is integrally formed on the above-mentioned input shaft, and the sun gear (34) of the motor shaft (33) and the planetary gear mechanism (28) is integrally formed.

[0077] Also, above-mentioned piston pump (30) and motor (31), as above-mentioned each embodiment, replace floating type valve plate (65) and use general valve plate (90), use coil spring (92) to this shutter ( 90) is tightly pressed on the friction plate part (91) arranged on the back side of the end cover (41).

[0078] Have again, above-menti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com