Cleaning liquid composition after chemical and mechanical grinding

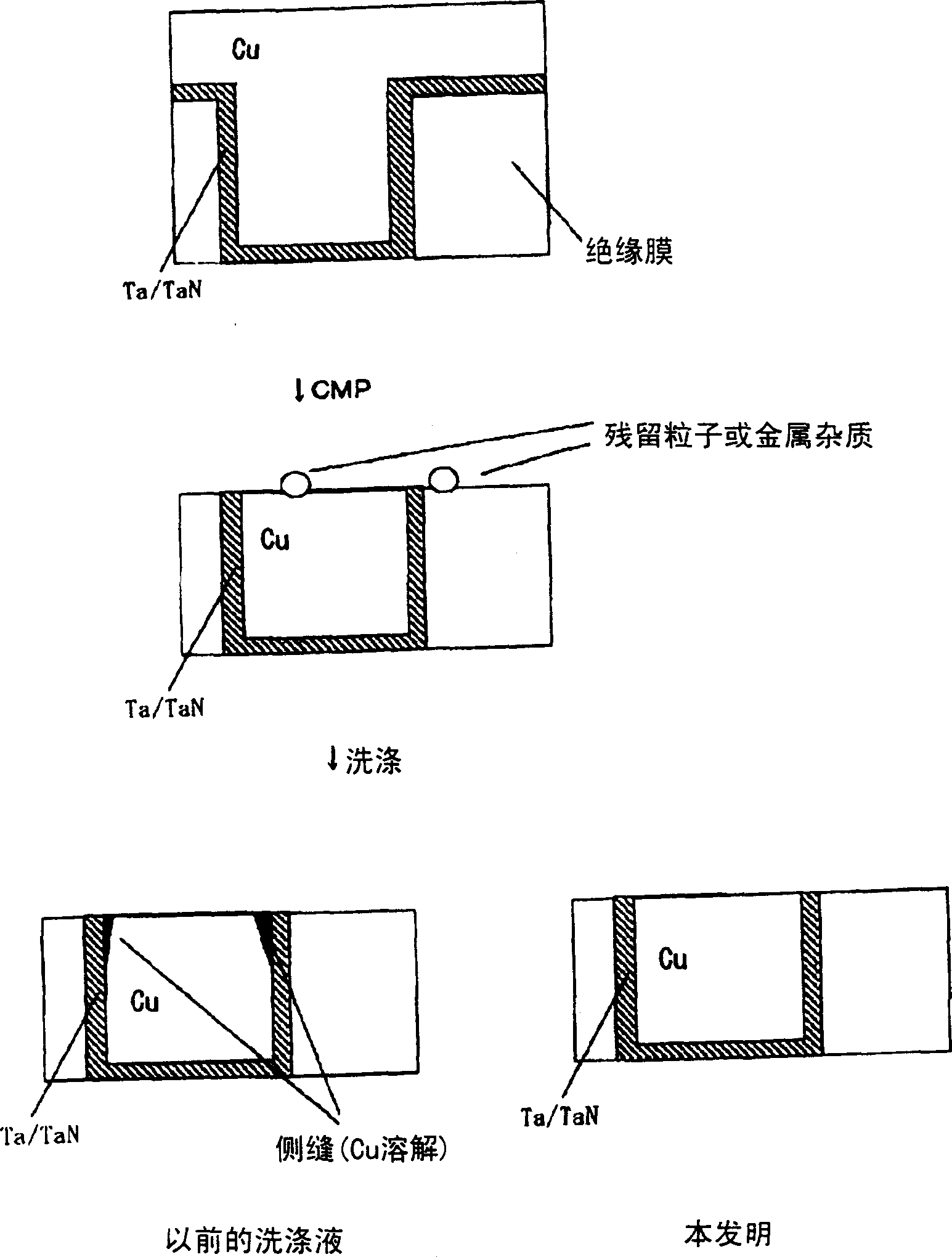

A chemical-mechanical, post-washing technology, applied in the field of washing liquid, can solve the problems of copper corrosion, not being satisfied with washing liquid at the same time, and achieve the effect of suppressing side seams

Inactive Publication Date: 2003-11-26

RENESAS ELECTRONICS CORP

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the higher the pH, the easier it is to generate side seams, and the decomposition of the reducing agent is likely to occur, and there are also problems such as microscopic corrosion of copper caused by ammonia-based compounds.

[0010] For such conventional wiring materials and interlayer insulating films, various cleaning solutions have been obtained, but the current situation is that there is no simultaneous solution for the exposure of copper wiring, or even for semiconductor substrates with a structure in which copper is in contact with dissimilar metals. Washing fluids that meet the above needs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0033] Hereinafter, based on the cleaning liquid composition after chemical mechanical polishing of the present invention, the present invention will be described in detail through examples and comparative examples, but the present invention is not limited to these examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A post-CMP washing liquid composition is provided which includes one type or two or more types of aliphatic polycarboxylic acids and one type or two or more types selected from the group consisting of glyoxylic acid, ascorbic acid, glucose, fructose, lactose, and mannose, and which has a pH of less than 3.0. This washing liquid has excellent performance in removing micro particles and metal impurities adhering to the surface of a semiconductor substrate after CMP and does not corrode a metal wiring material.

Description

technical field [0001] The present invention relates to a cleaning solution, in particular to a cleaning solution for the surface of a semiconductor substrate on which metal wiring materials (especially copper) are exposed. [0002] The present invention also relates to a cleaning solution for removing minute particles and metal impurities attached to the surface of a semiconductor substrate after chemical mechanical polishing (CMP), especially in a semiconductor manufacturing step. Background technique [0003] With the high integration of integrated circuits, since trace particles and metal impurities have a great impact on the performance and yield of devices, strict pollution control is required. That is, strict control of particles and metal impurities adhering to the substrate surface is required, and various cleaning solutions are used in each process of semiconductor manufacturing for this purpose. [0004] Generally, there are sulfuric acid-hydrogen peroxide, ammon...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C11D1/00C11D3/20C11D7/26C11D11/00C11D17/08G03F7/32H01L21/02H01L21/304

CPCC11D7/26C11D3/2075C11D11/0047H01L21/02074G03F7/32

Inventor 阿部优美子大和田拓央石川典夫青木秀充富盛浩昭

Owner RENESAS ELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com