New technological method-2 for detecting shear wave speed in geotechnical static and dynamic triaxial instrument

A dynamic three-axis, shear wave technology, applied in the direction of soil material testing, instruments, measuring devices, etc., can solve the problems of reducing shear wave energy, limiting the service life of devices, and not being able to use sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

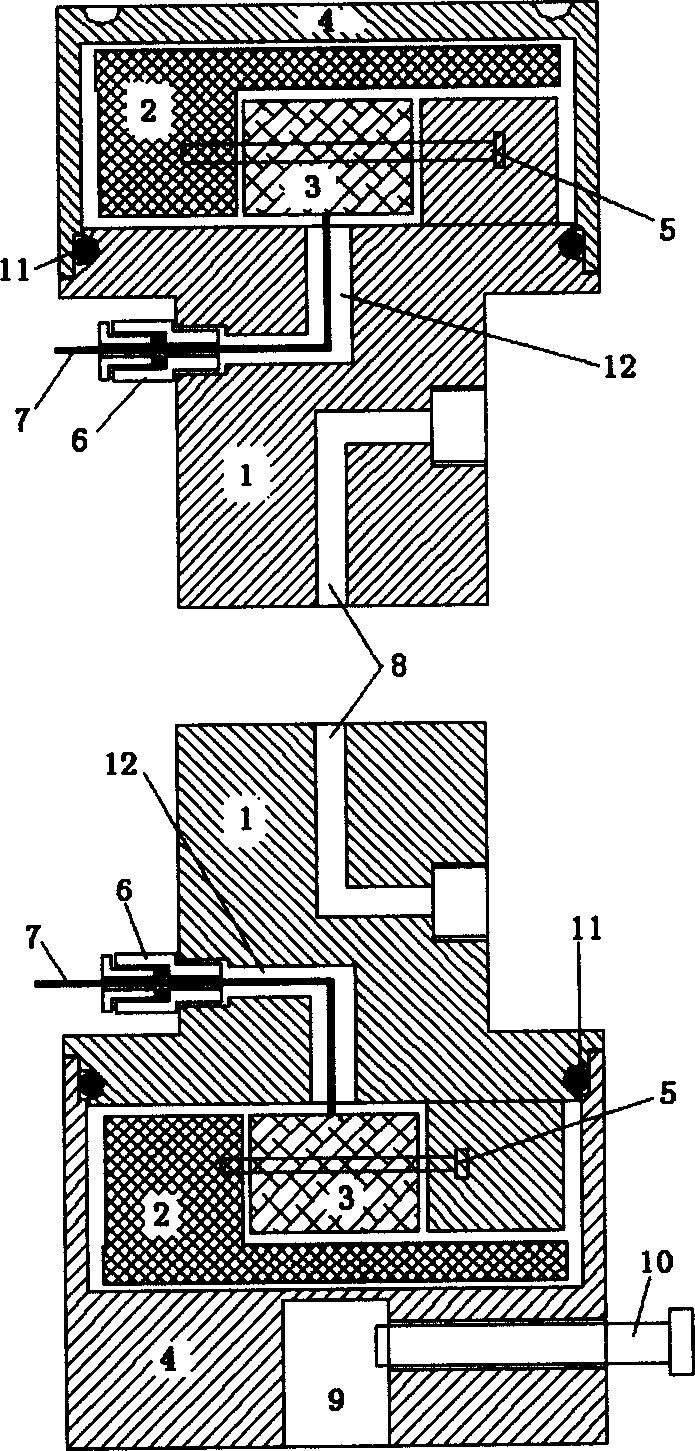

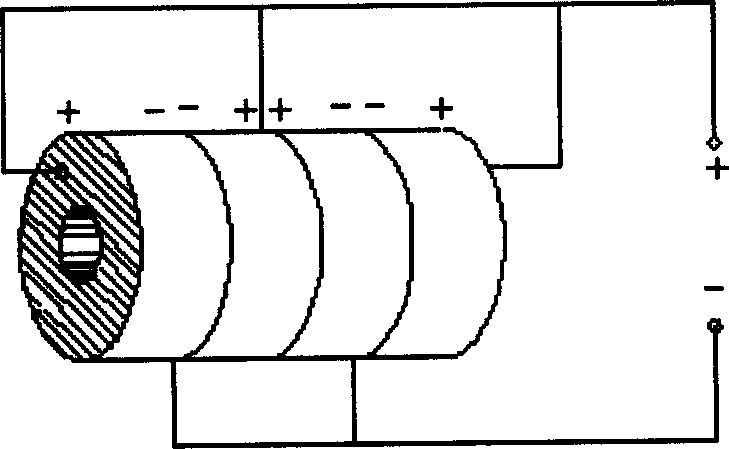

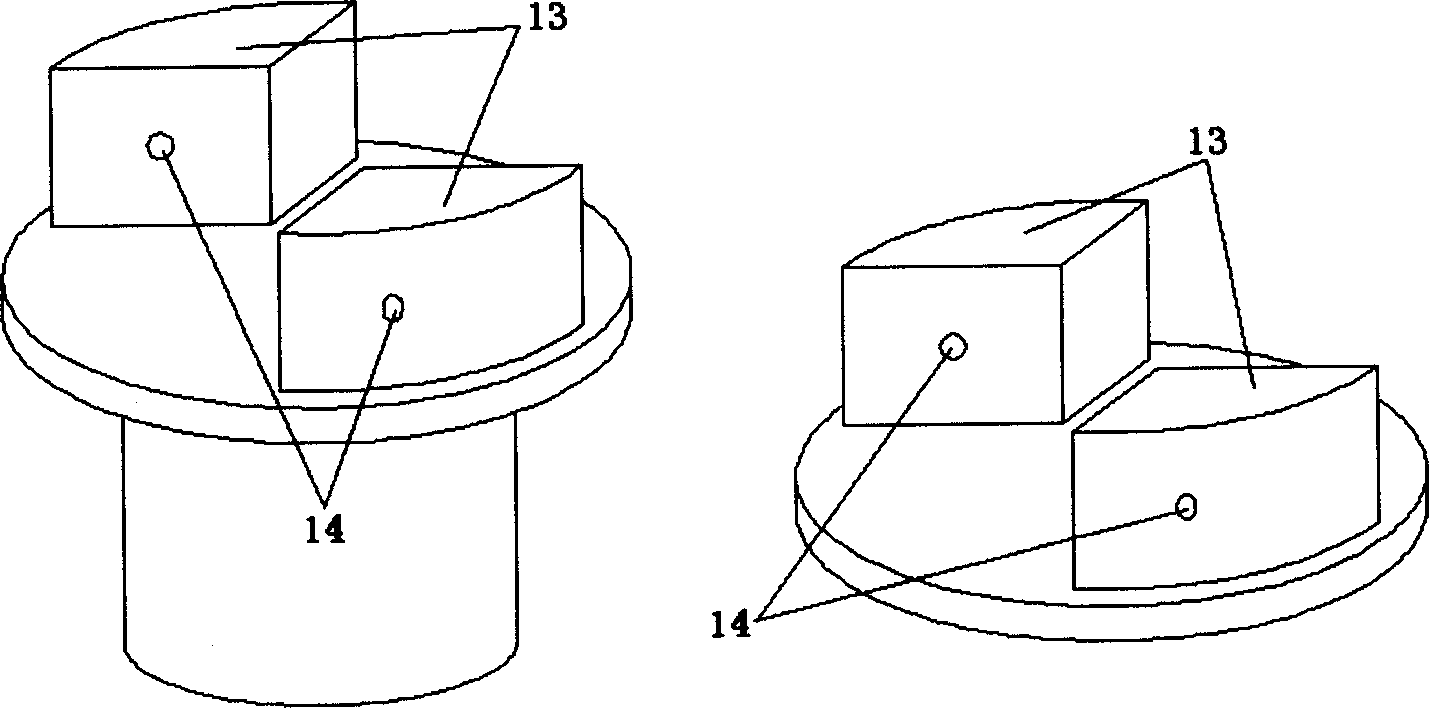

[0009] Refer to attached Figure 1~4 . Among them, the front cover (1) is made of light hard metal, the rear cover (2) is made of heavy metal such as stainless steel or copper, the diameter of the front and rear cover is φ39.1mm, the diameter of the shell (4) is φ70mm, the upper sensor The height is 50mm and the lower sensor is 70mm. First, the electrodes of the piezoelectric composite ceramic rod pair (3) are connected well, and the cable (7) protrudes from the cable outlet hole (12) to the outside of the front cover plate (1). Then use the assembly bolts (5) to pass through the pair of piezoelectric composite ceramic rods (3) and the bolt holes (14) of the fan-shaped cylinder to fix the front and rear cover plates together. An O-ring is put on the groove of the front cover (1), and the front cover, the rear cover and the piezoelectric composite ceramic rod are placed in the shell (4). Finally, the outgoing cable (7) is passed through the cable outgoing joint (6) and fixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com