Replicating position arrival hydraulic machine controlling device

A technology for control devices and implements, which is applied to fluid pressure actuation devices, hoisting devices, accumulator devices, etc., can solve the problems of difficult sealing, difficult to achieve repeated no-load placement, complicated disposal, etc., and achieve punctual and reliable sealing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

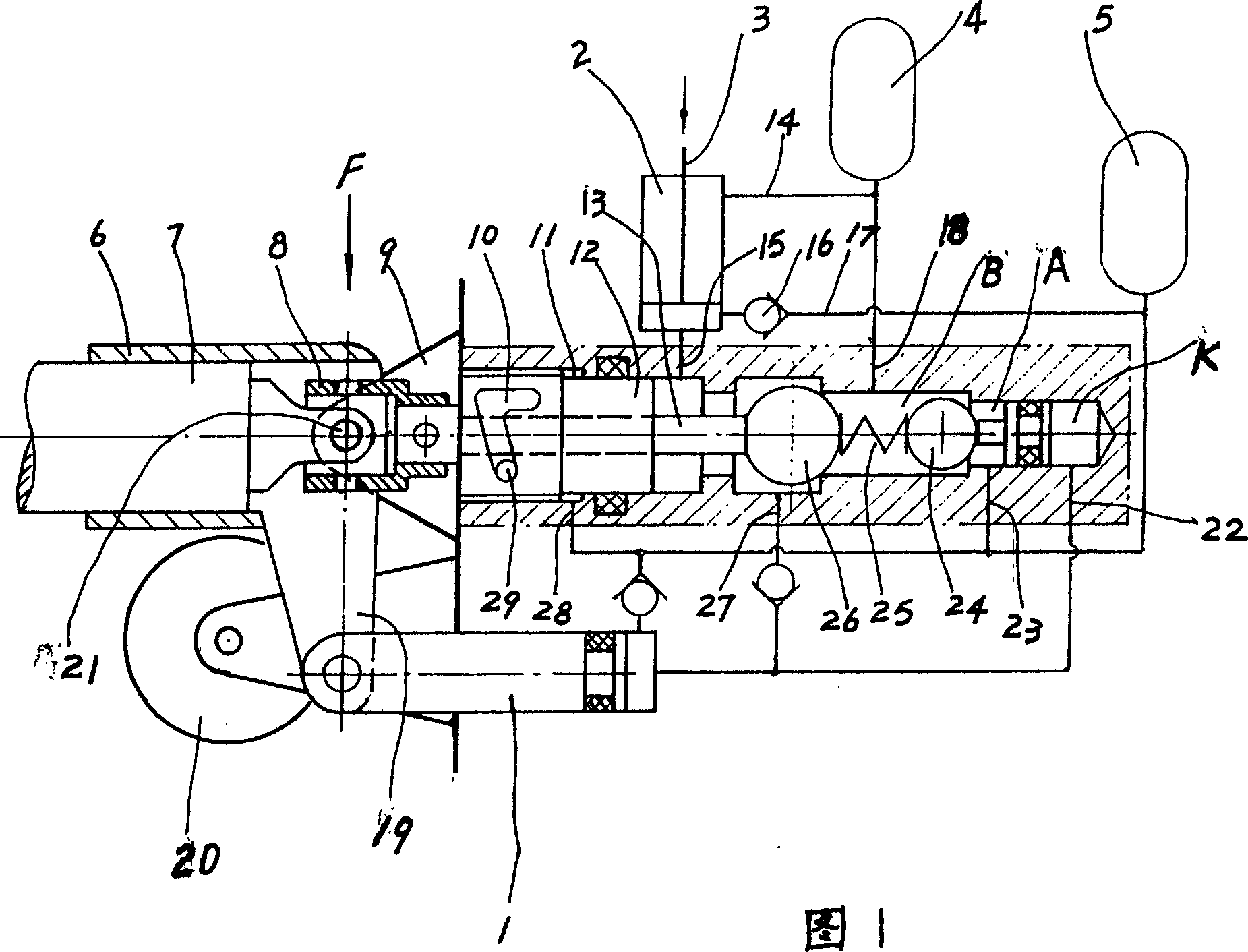

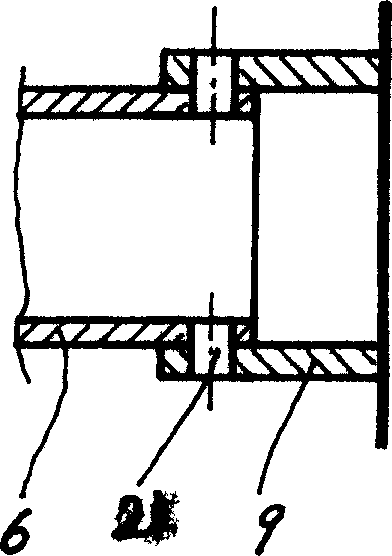

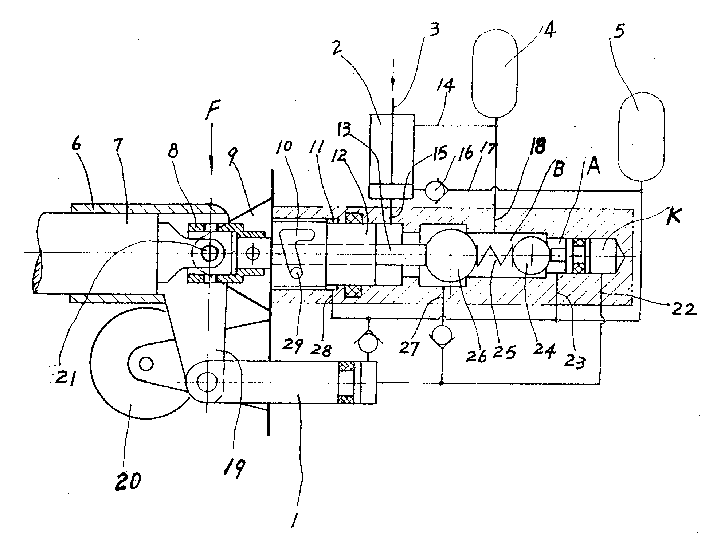

[0010] With reference to the accompanying drawings, one consists of an oil pump 1, an oil cylinder 2, a piston 3, a high-pressure stage accumulator 4, a low-pressure stage accumulator 5, and a two-position two-way oil return rotary valve 12, a double-control check valve 26, and a hydraulic control valve. The combined control device of the one-way valve 24 constitutes the full hydraulic implement of the present invention. The accumulator 4 communicates with the upper cavity of the oil cylinder 2 through the channel 14; the accumulator 5 communicates with the lower cavity of the oil cylinder 2 through the channel 17 and the one-way valve 16. In the oil return rotary valve 12 in the control device, the large diameter of the valve core is connected with the valve body through threads, and the small diameter is closely matched with the valve body. There is a hook-shaped groove 10 on the valve core cylinder, and the center is a through hole. Cooperate with a push rod 13. A spring 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com