Internal energy drive adjustment structure of turbine blades

A technology for adjusting structures and water turbines, applied to machines/engines, mechanical equipment, hydroelectric power generation, etc., can solve problems such as poor sealing, oil leakage, rotating seal transmission, operating oil pressure, restrictions, etc., to reduce installation costs and reduce manufacturing and processing costs The effect of reducing and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

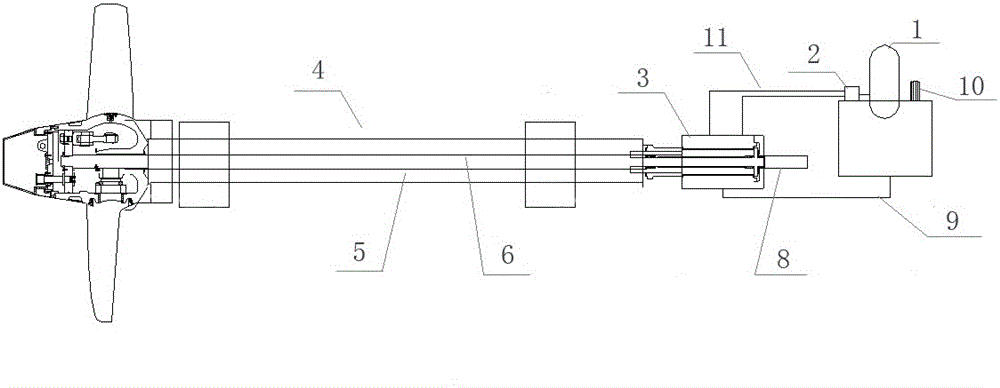

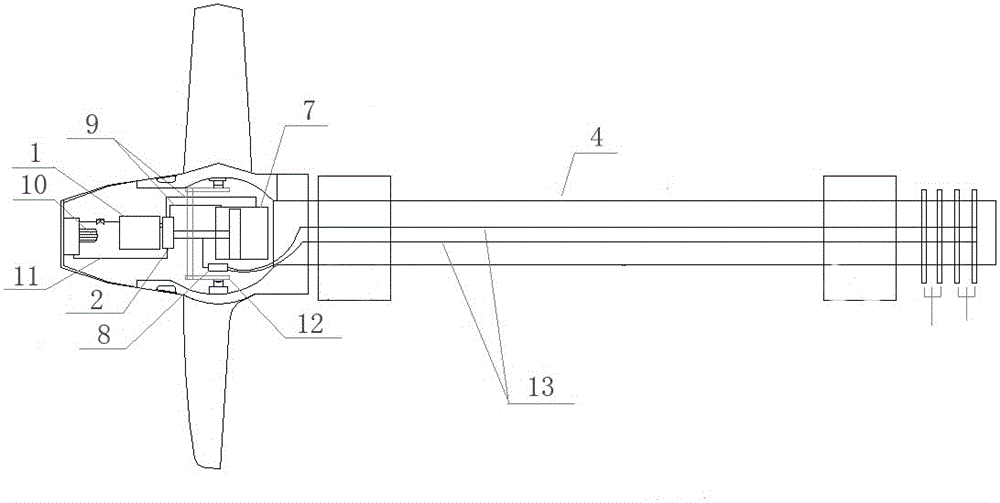

[0012] Such as figure 2 As shown, the internal energy drive adjustment structure of the turbine blade includes a pressure energy storage system, an operating system and an execution system, wherein the pressure energy storage system includes an oil tank, an accumulator 1, an oil pump 10 and an automatic pressure control link, and the operating system includes a digital valve 2 and a displacement sensor 8, the execution system includes an operating link 12 and a blade servomotor 7, the pressure energy storage system, the operating system and the execution system are installed inside the blade hub, the energy storage 1, the oil pump 10, the digital valve 2 The three are horizontally arranged concentrically and are directly connected to the blade servomotor 7 through the oil pipelines 9 and 11. The electrical signal of the blade is led out to the control system through the slip ring of the inner cavity cable 13 of the main shaft 4 for control.

[0013] The internal energy drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com