Double screw extruder suitable to hierarchy of middle-high viscosity

A twin-screw extruder and high-viscosity technology, applied in the field of twin-screw extruders, can solve the problems of long residence time of materials, poor conveying effect, large shearing effect of materials, etc., and achieve the effect of quality optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

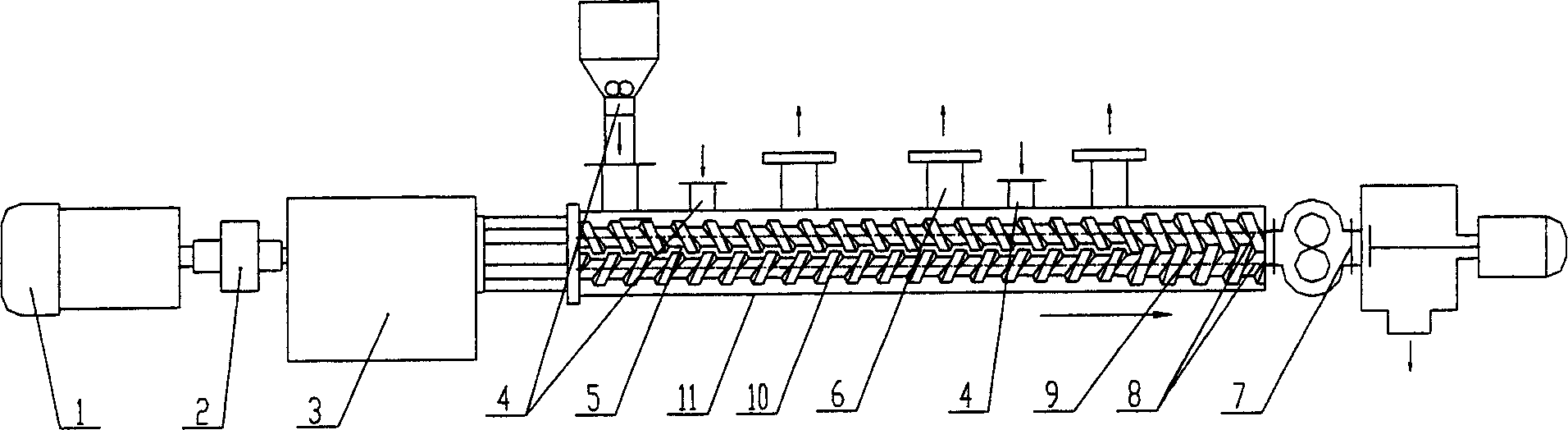

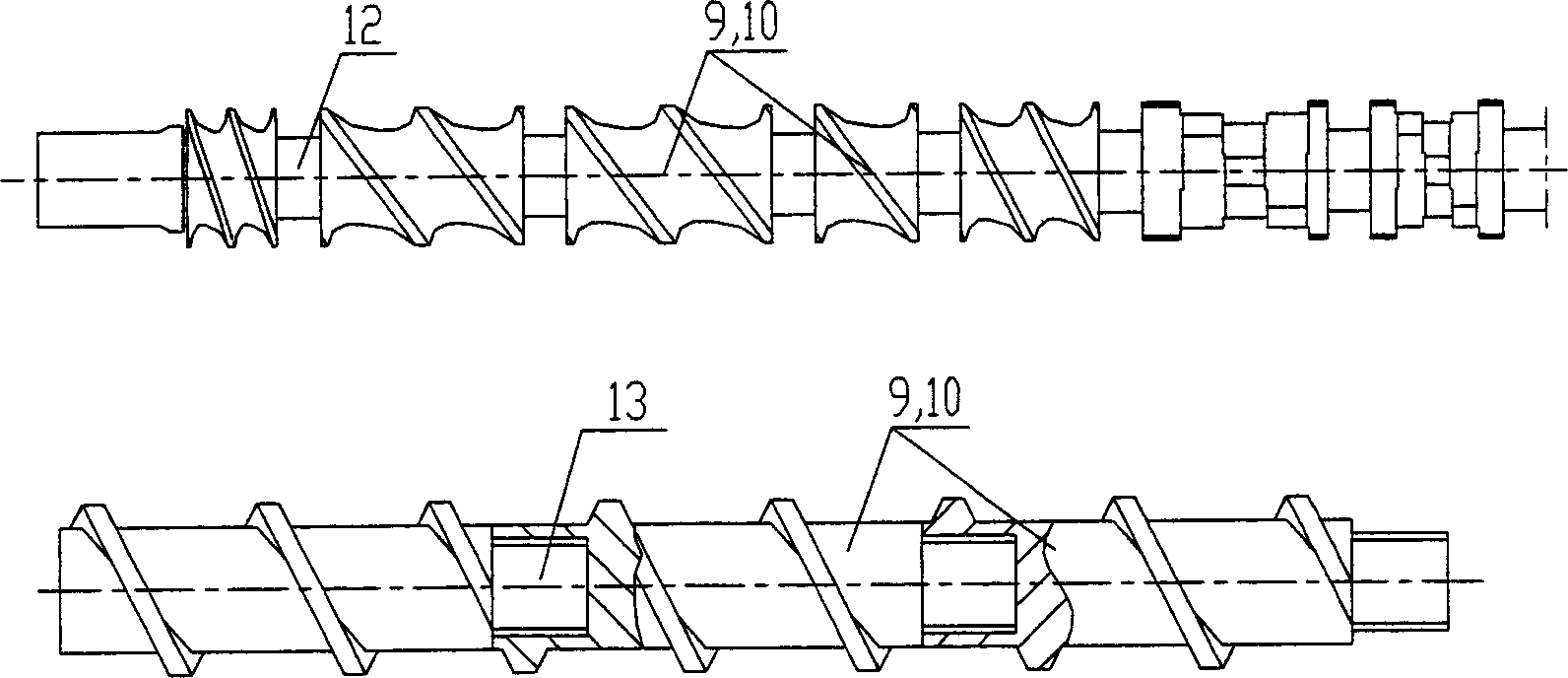

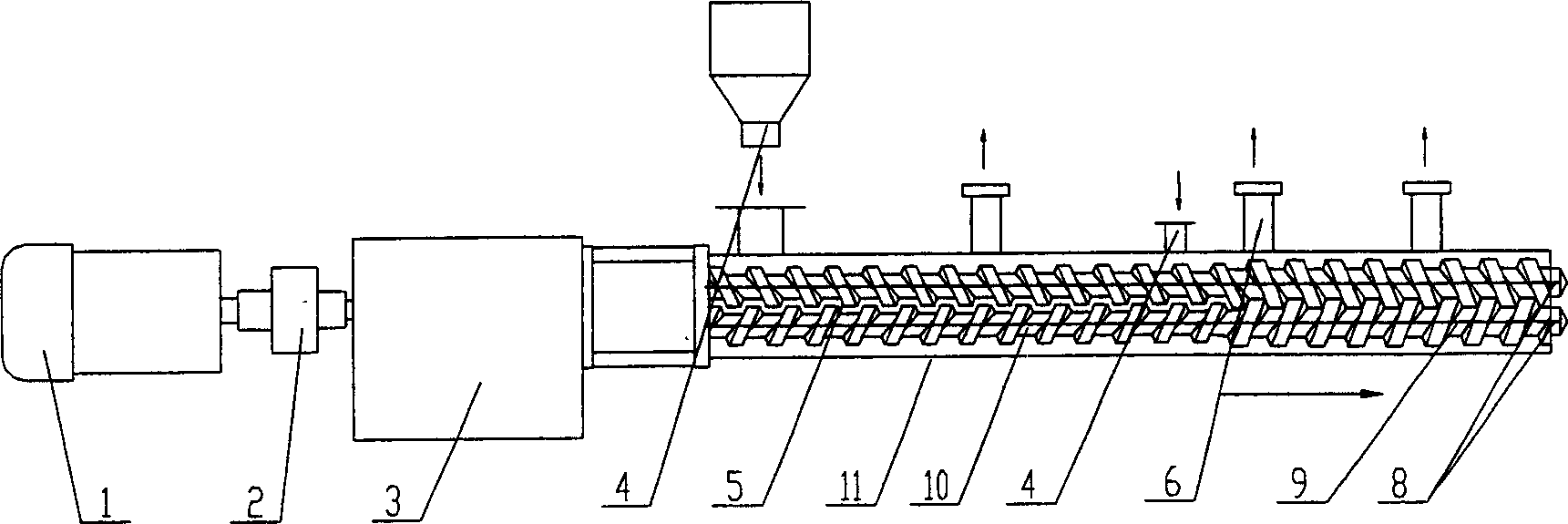

[0019] The present invention uses the following specific embodiments to further illustrate the present invention in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the specific embodiments. The twin-screw extruder used for medium and high viscosity systems provided by the present invention comprises a drive motor 1, a shaft coupling 2, a gear box 3, a feeding system 4, a conveying and mixing system 5, a devolatilization exhaust system 6 and an extrusion cutter. Granulation system 7, the conveying and mixing system 5 is mainly composed of a cylinder 11, a screw mandrel 12, screw elements 9, 10, and a screw temperature control system (not shown). The motor 1 transmits power to the gearbox 3 through the coupling 2, and the gearbox 3 distributes the power to two output shafts. The output shafts are connected to the conveying mixing system 5, and the output shafts drive the screw mandrels to rotate in the same direction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Center distance | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com