Evaporation cooled device for stator of steam turbo-generator and hydraulic generator

A hydro-generator, evaporative cooling technology, applied in cooling/ventilation devices, electromechanical devices, electrical components, etc., can solve the problems of secondary cooling water entry, short circuit, and difficulty in avoiding accidents in cooling water pipes, so as to avoid short circuit accidents. , the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

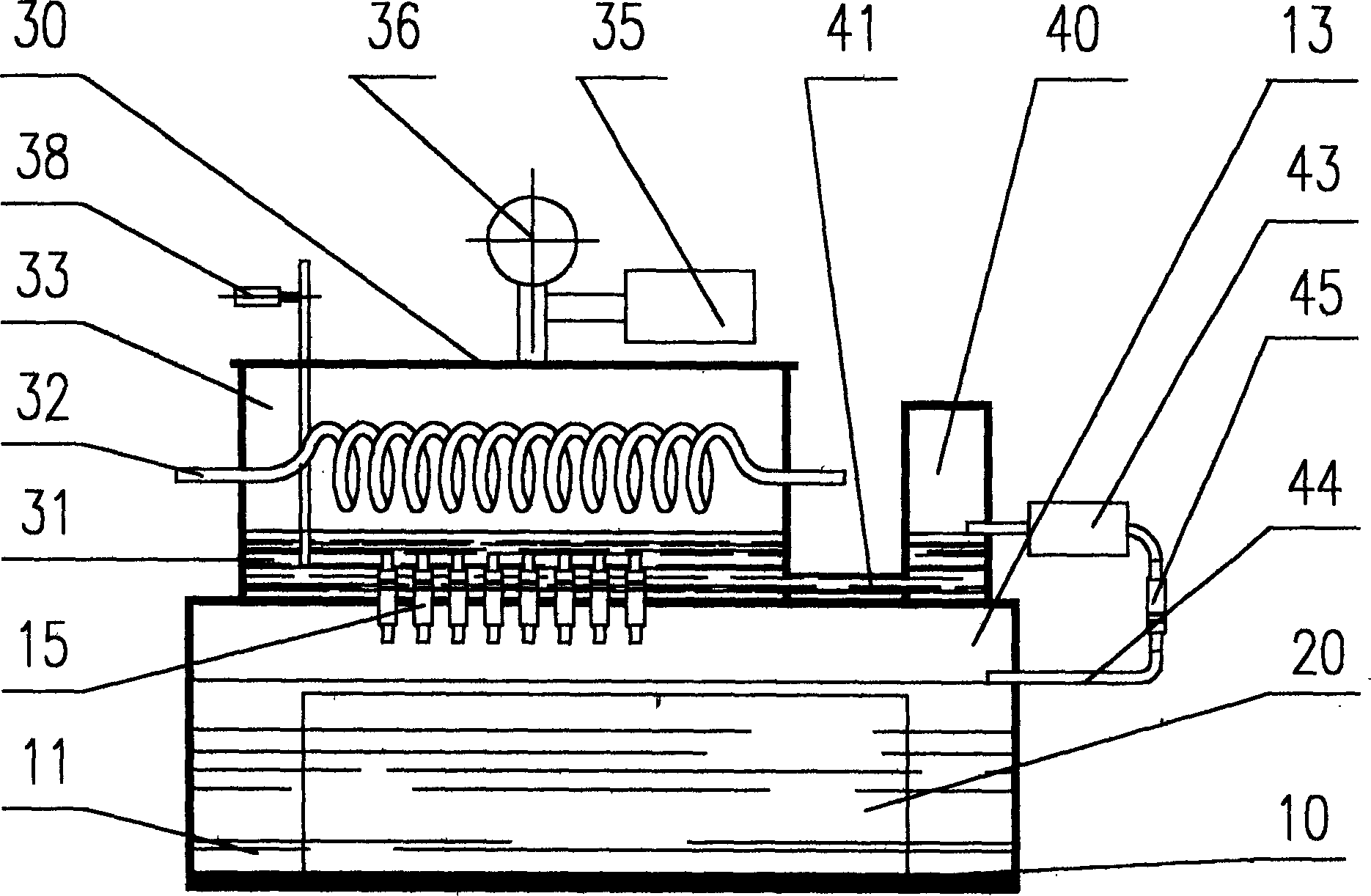

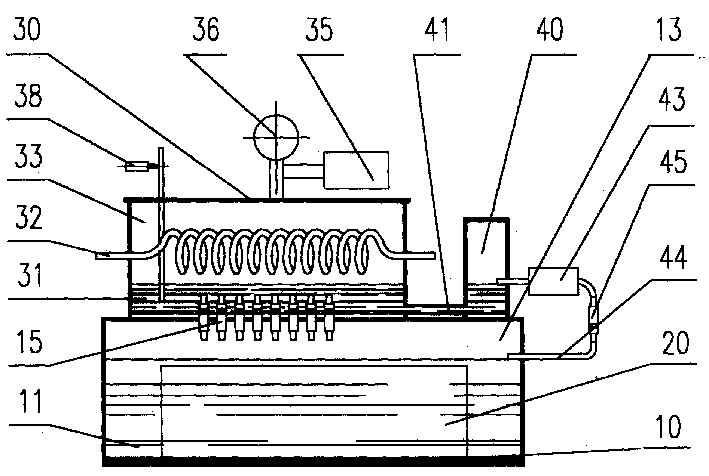

[0011] figure 1 It is an embodiment of the evaporative cooling device of the present invention. Generator stator heating components 20 are immersed in the liquid cooling medium 11 in the lower part of the evaporative cooling chamber 10 . The upper part of the evaporative cooling chamber 10 is an evaporative space 13 . The condenser 30 located above the evaporative cooling chamber 10 is isolated from the former, and a one-way valve group 15 is installed between the evaporation space 13 and the bottom of the condenser 30 . The upper part of the condenser 30 is a condensation space 33 , and the lower part is a liquid storage chamber 31 . The one-way valve group 15 only allows the cooling medium vapor in the evaporation space 13 to enter the condenser 30 through it. A cooling water pipe 32 is installed in the condensing space 33 of the condenser, and secondary cooling water circulates in the cooling water pipe 32 . A water leakage detector 38 and a pressure controller 36 are i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com