Gripping implement with improved arrangement

A technology for improving structures and tools, applied in the field of holding tools, can solve problems such as troublesome identification, sticking, and inconvenient use, and achieves the effects of cost-effectiveness, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below, with reference to the accompanying drawings and preferred embodiments, the specific implementation, structure, features and functions of the gripping portion with improved structure proposed according to the present invention will be described in detail as follows.

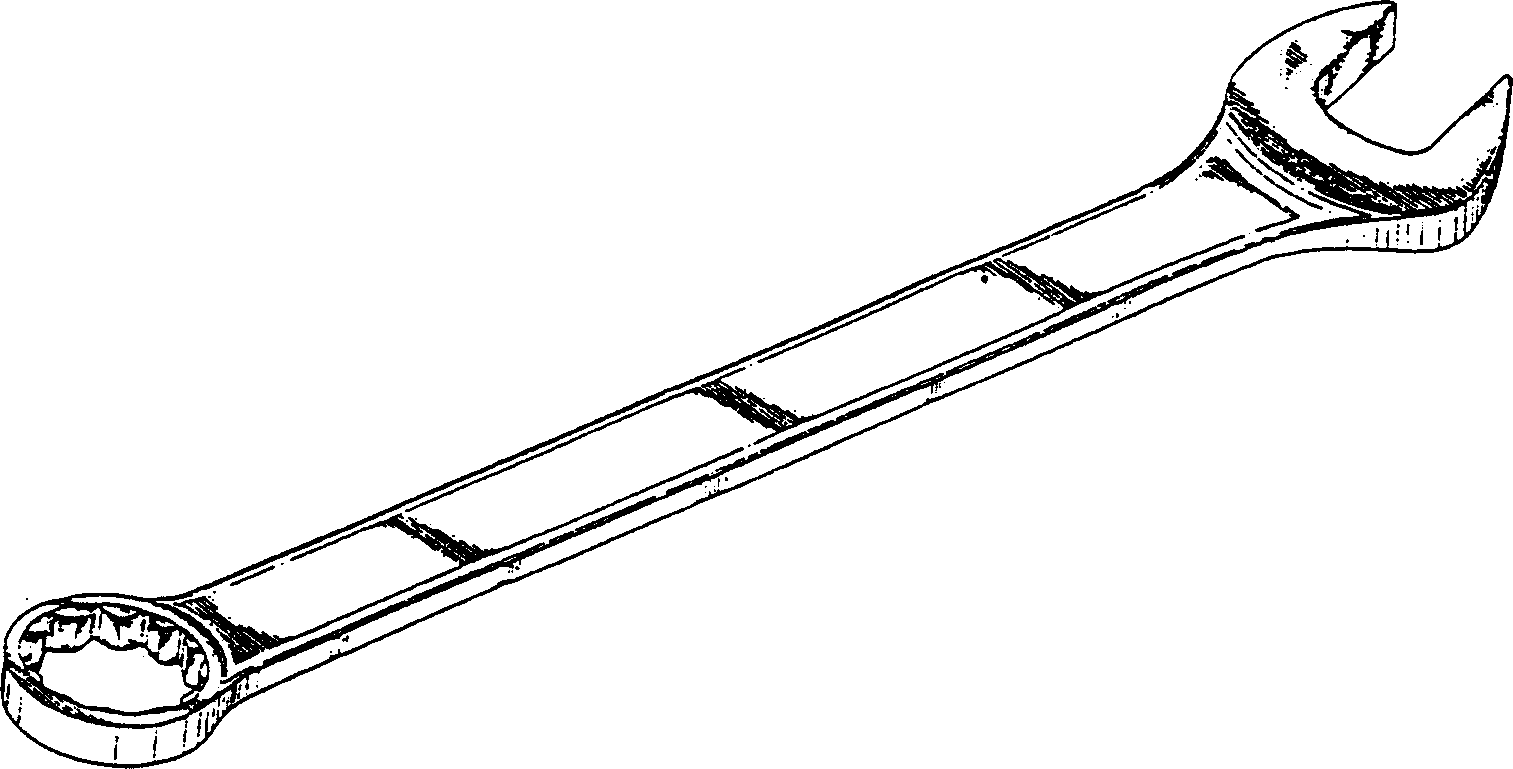

[0023] figure 1 In the existing conventional grip structure shown, the grip tool body 1 is smooth.

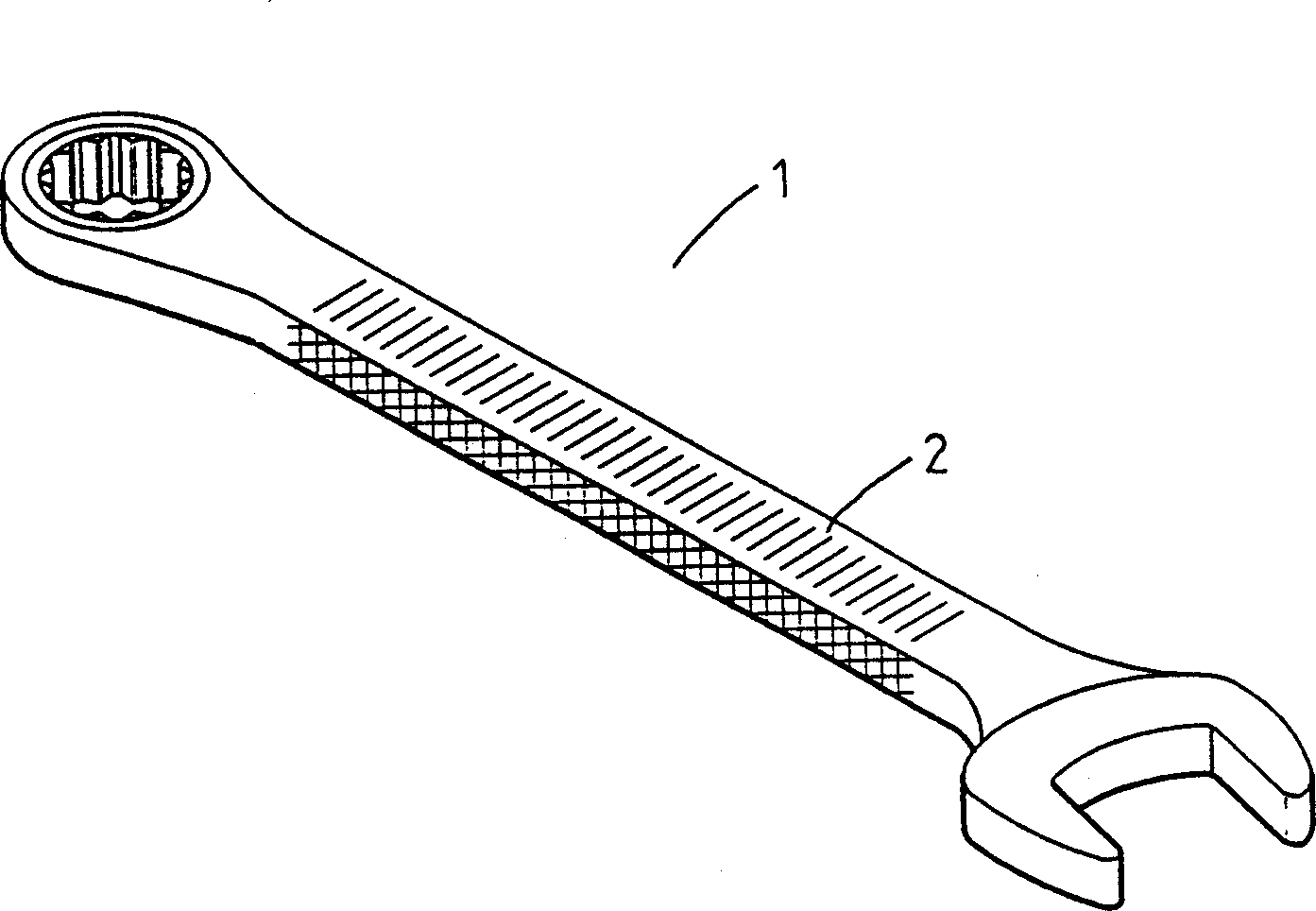

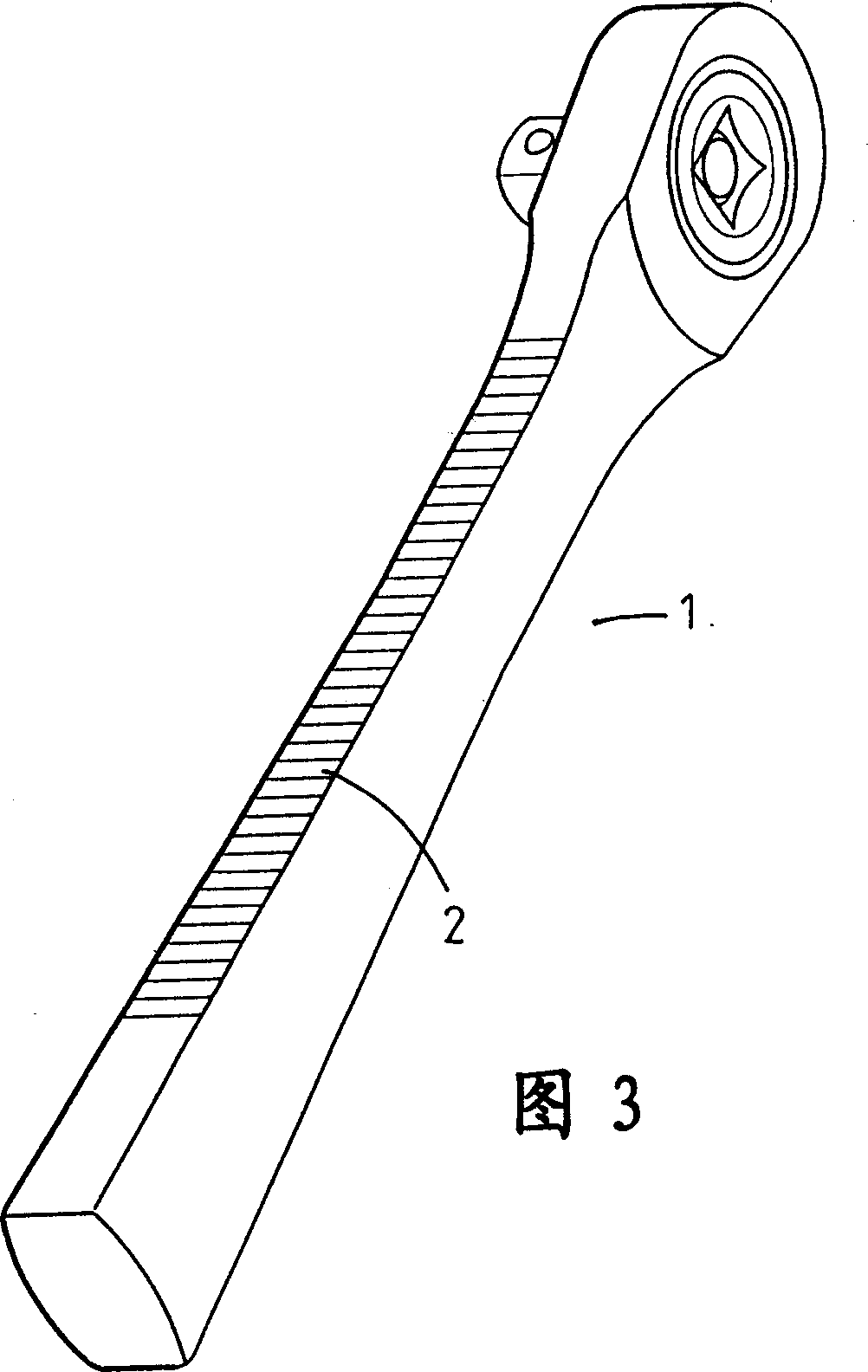

[0024] Figure 3 and Figure 7 to Figure 13 As shown, the holding tool with improved structure of the present invention mainly includes a holding tool body 1 , and an embossed portion 2 is formed on at least one side of the holding tool body 1 . The embossed portion 2 can be straight grain, twill grain, cross grain or a combination of straight grain and cross grain.

[0025] Such as figure 2 As shown in FIG. 4 to FIG. 6 , the holding tool with improved structure of the present invention mainly includes a holding tool body 1 , and embossed parts 2 are formed on both sides of the holding tool body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com