Vacuum system for energy conservation water extraction vapor

A vacuum pumping system and vacuum system technology, applied in energy-saving heating/cooling, lighting and heating equipment, climate change adaptation, etc., can solve the problems of water waste, affecting the application of vacuum technology, large energy consumption, etc., and achieve sufficient condensation absorption. , novel structure, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

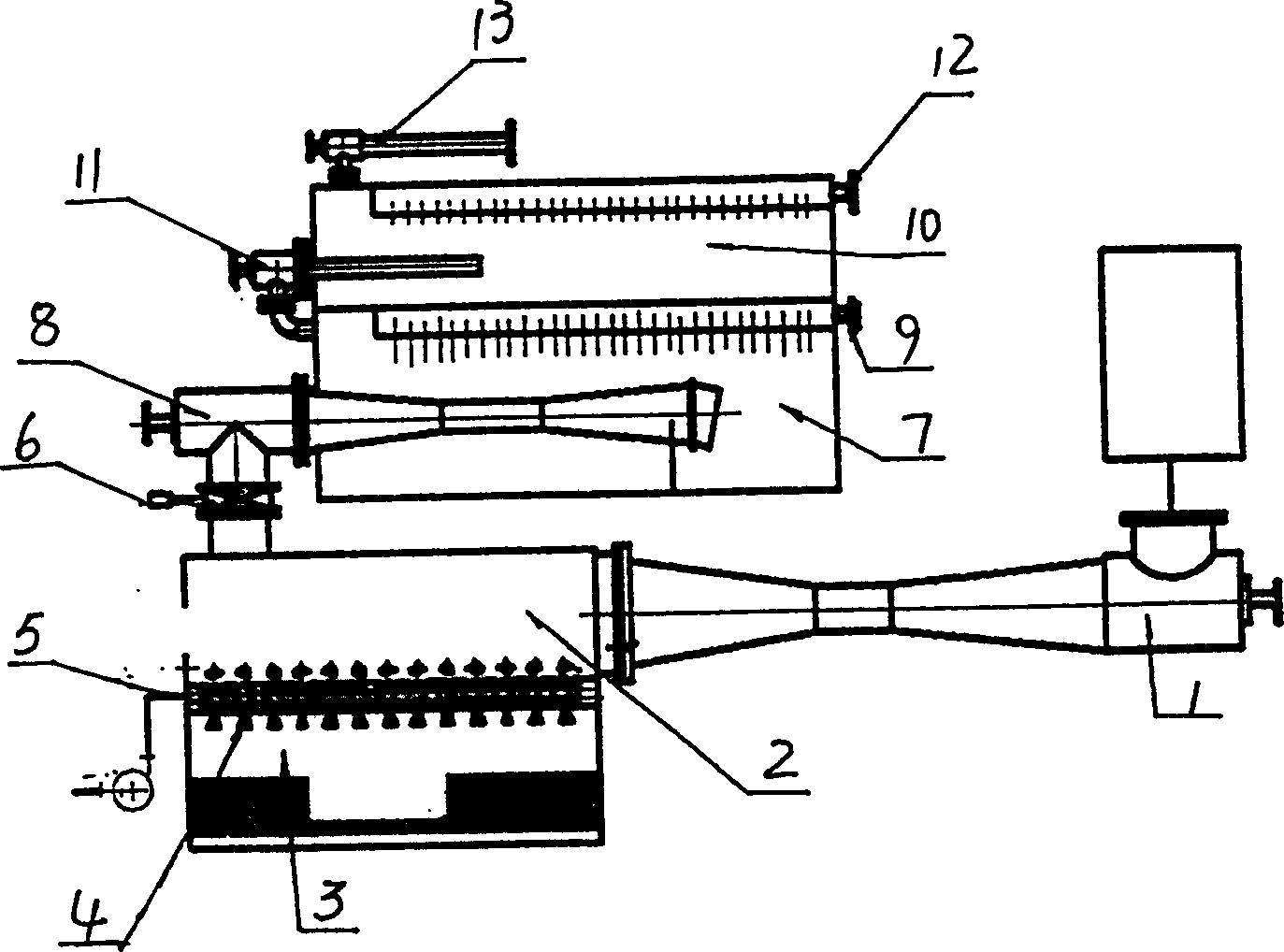

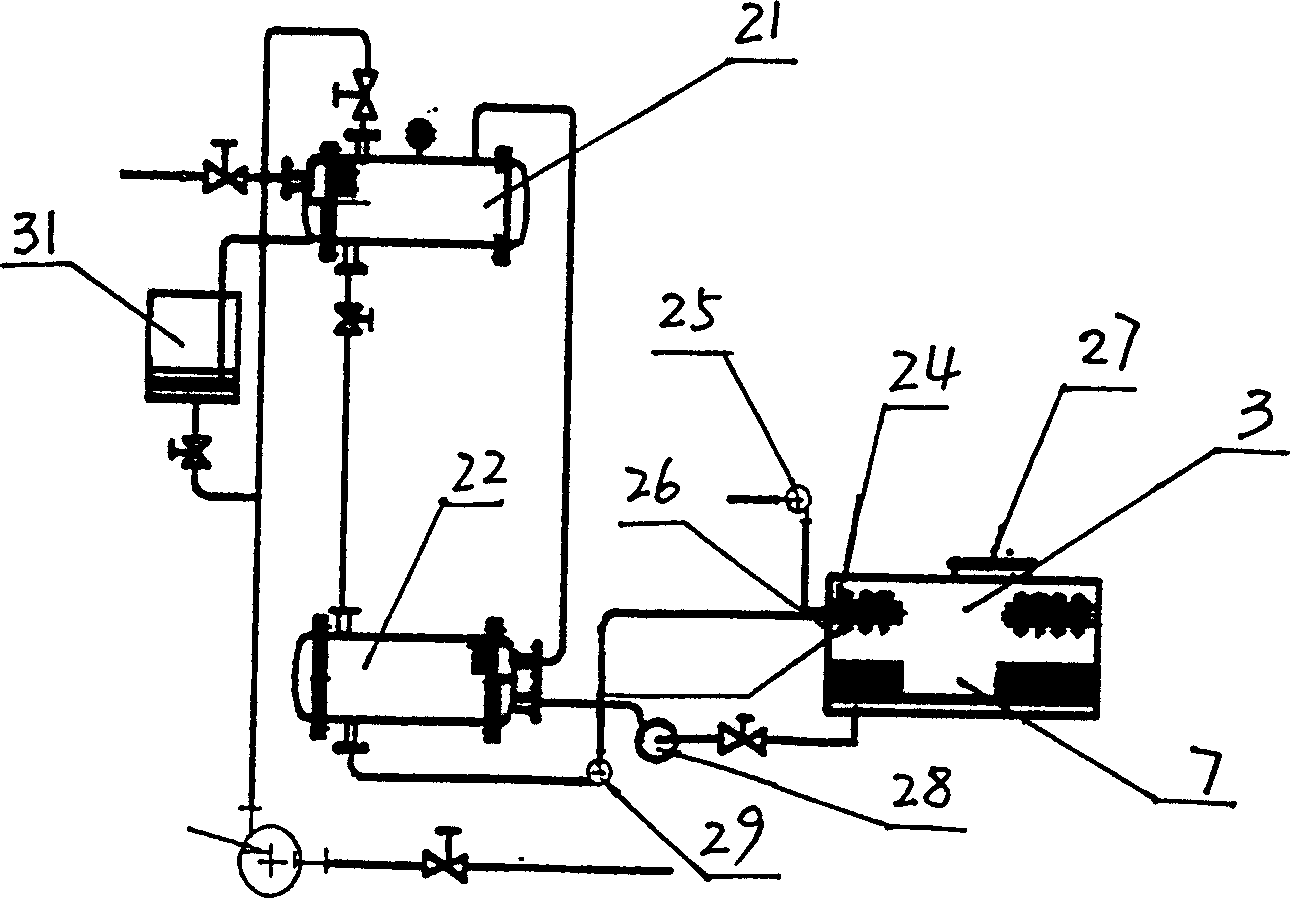

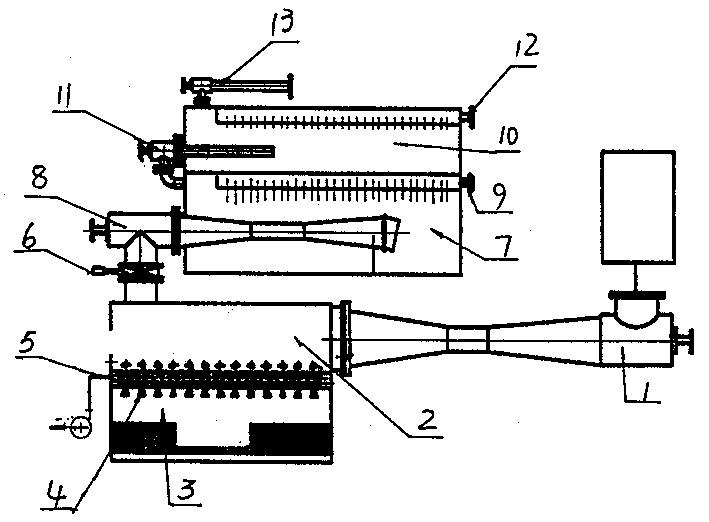

[0013] A new type of vacuum system for pumping water and steam such as figure 1 and figure 2 As shown, it consists of main steam jet vacuum pump 1, lithium bromide absorption system 2, absorber 3, spray piping system 4, exhaust piping system 5, valve 6, condenser 7, primary ejector 8, cooling water inlet 9, condenser 10. Composed of secondary injector 11, cooling water inlet 12, tertiary injector 13, vacuum pump, etc.

[0014] When working, first open the third-stage ejector 13, and then turn on the condenser 10 cooling water after reaching the vacuum degree requirement, then turn on the condenser 7 cooling water, and the second-stage ejector 11; after reaching the vacuum degree requirement, open the first-stage ejector 8, and the vacuum degree When the lithium bromide absorption system 2 absorbs the environmental requirements, the valve 6 is closed, and the pre-vacuum system is closed. At this time, the main steam jet vacuum pump 1 is turned on, and the lithium bromide abso...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap