Water solution system local corrosion speed online electrochemistrical monitoring probe

A localized corrosion and chemical monitoring technology, applied in the direction of measuring devices, instruments, mechanical devices, etc., can solve problems such as difficulty in determining corrosion, costing more time and cost, and inability to measure localized corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

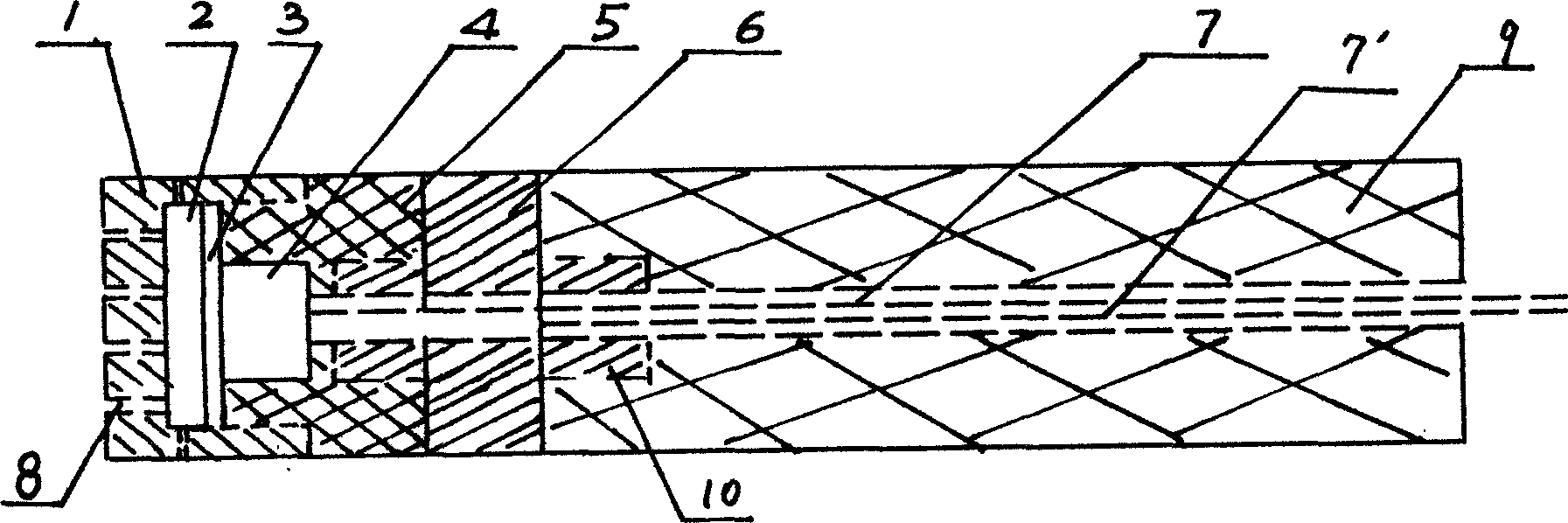

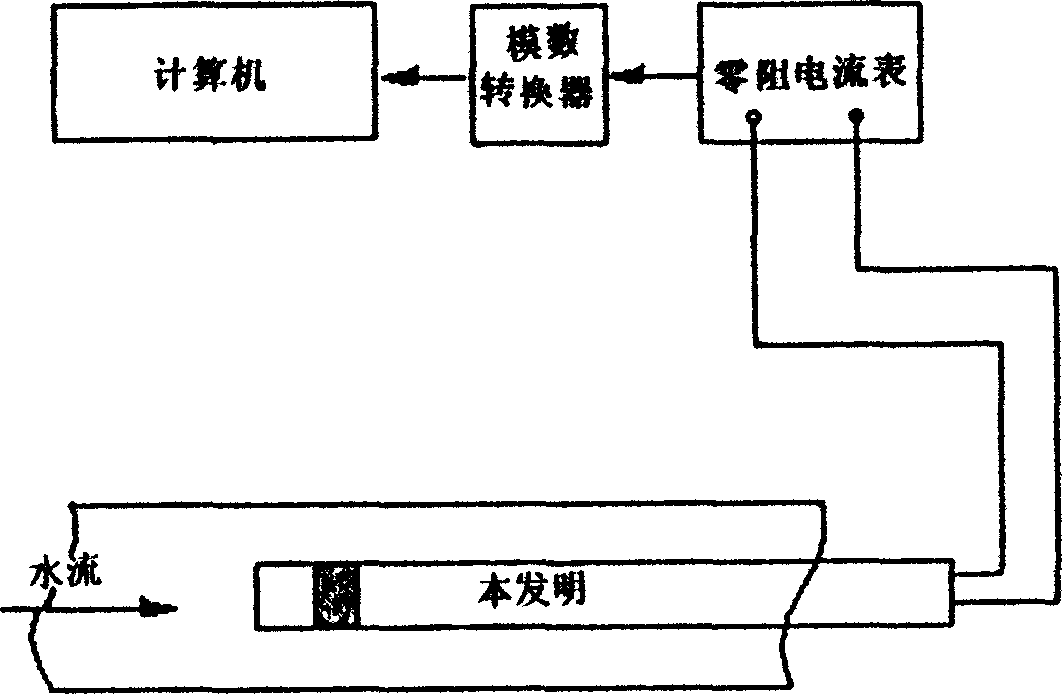

[0013] Such as figure 1 As shown, the present invention is a two-electrode system structure, which is mainly composed of a sheath 1, a filter membrane 2, a closed anode area 3, an anode 4, a sealing joint 5, a cathode 6 and a tail sleeve 9, wherein:

[0014] The front cover 1 is crown-shaped, and the inner end wall is provided with a filter membrane 2, and the sealing joint 5 accommodates the anode 4 in a groove thereof, and is connected with the inner side wall of the front cover 1 by a screw thread, and the filter membrane 2 is connected to the inner wall of the front cover 1. A blocked anode region 3 is formed between the surfaces of the anode 4;

[0015] The cathode 6 is a cylinder whose outer surface is an effective cathode surface area in contact with the bulk electrolyte. The two ends of the cathode 6 are provided with a thinner cylinder 10 with threads, and one end is connected to another groove of the sealing joint 5 The inner wall is tightly matched with threads, an...

Embodiment 2

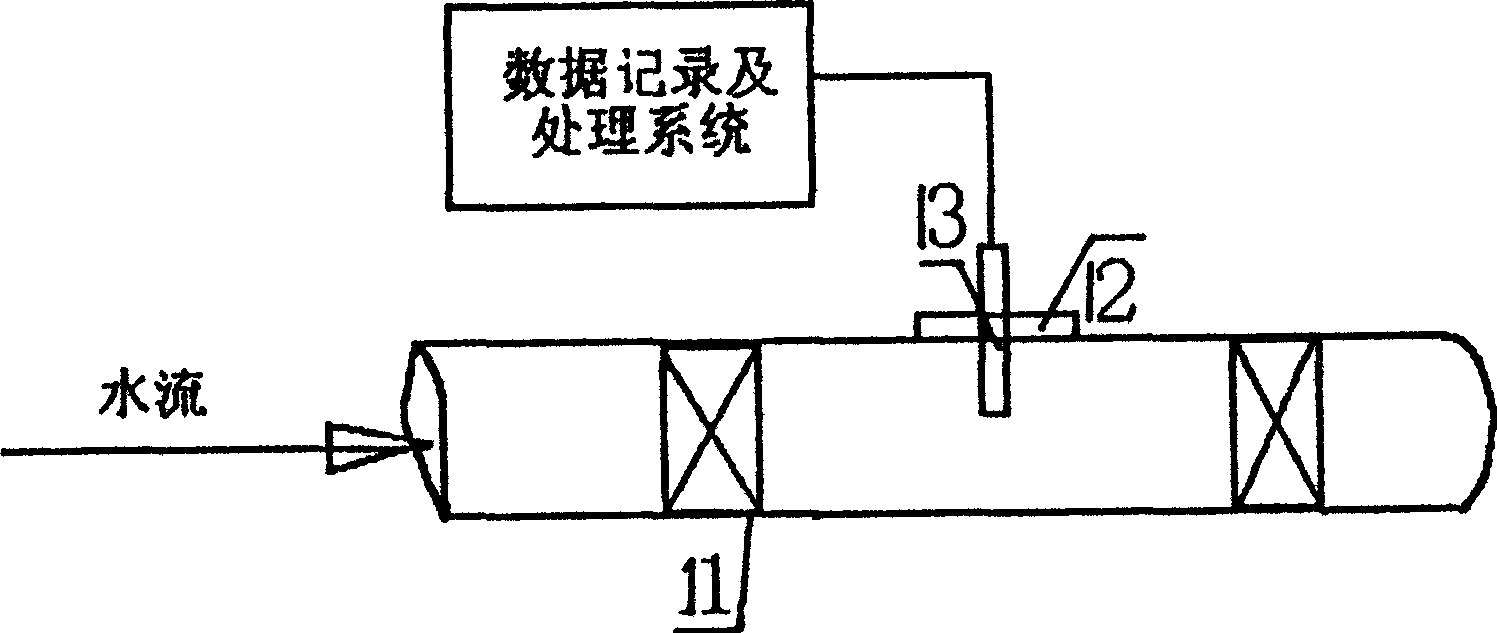

[0028] It is used to measure the local corrosion rate of seawater, and the probe can be directly placed in the area to be measured for measurement. In this embodiment, the surface area of the outer surface of the cathode 6 is 10 times that of the anode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com