Rail

A track and rail waist technology, applied in the field of railway track, can solve the problems of narrow available space, track wear, track vibration, etc., achieve broadband vibration reduction effect, improve service life, and good vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

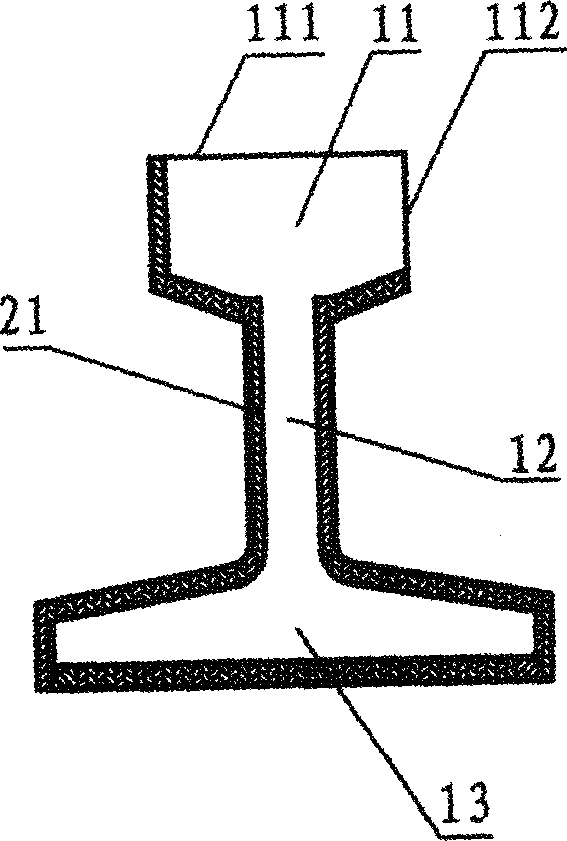

[0029] track of the present invention, see figure 1 , which includes a track body, which is composed of a rail head 11, a rail waist 12 and a rail bottom 13, and a layer of solid high damping is arranged on the non-working outer surface of the track body except the rail head top surface 111 and the side working surface 112 Material 21. The solid high-damping material is specifically made of high-damping modified asphalt that is solid at room temperature, and is made of rubber powder, talcum powder, mica powder, etc., and a layer of high-strength fiber mesh is embedded in the middle to make a damping coil. , hereinafter referred to as modified asphalt damping membrane. The solid high-damping material is a viscoelastic solid at normal temperature, and becomes a viscous liquid after heating, and can be integrated with the track body through self-adhesive, hot-melt bonding or thermal coating.

[0030] For the track of this structure, when the train is running, the vibration gene...

Embodiment 2

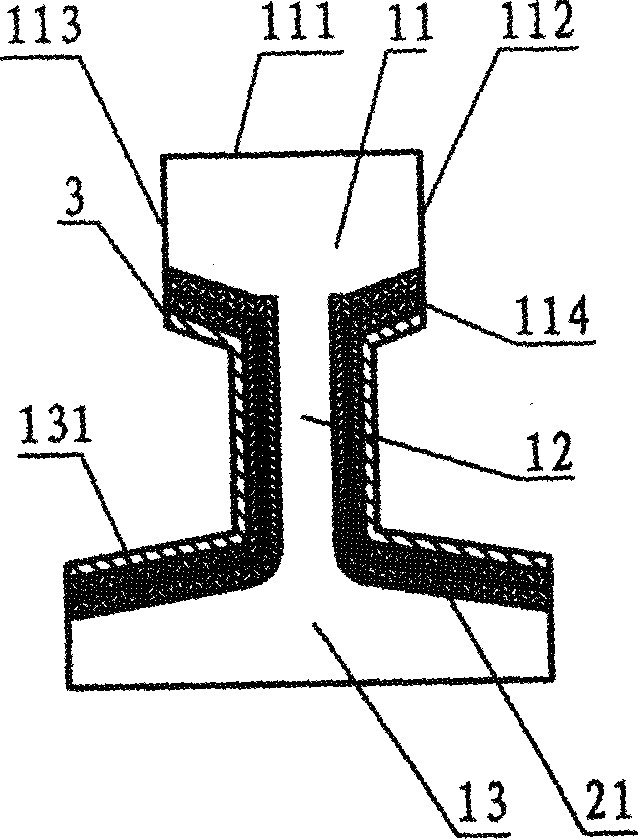

[0032] see figure 2, on the surface of the constraining structure 3, it is usually a relatively rigid aluminum plate or color steel plate, which is bent or rolled into a profile with a cross section similar to that of the rail waist 12, rail jaw 114 and rail bottom surface 131, or engineering plastic extrusion The profile, that is, the restraint plate, is hot-melted and pasted with two layers of solid high-damping material 21, which is still a modified asphalt damping coil, and made into a damping structure, and then the rail waist 12, rail jaw 114 and rail jaw 114 on the non-working surface of the track body The upper surface 131 of the rail bottom is directly hot-melt bonded to the rail body.

Embodiment 3

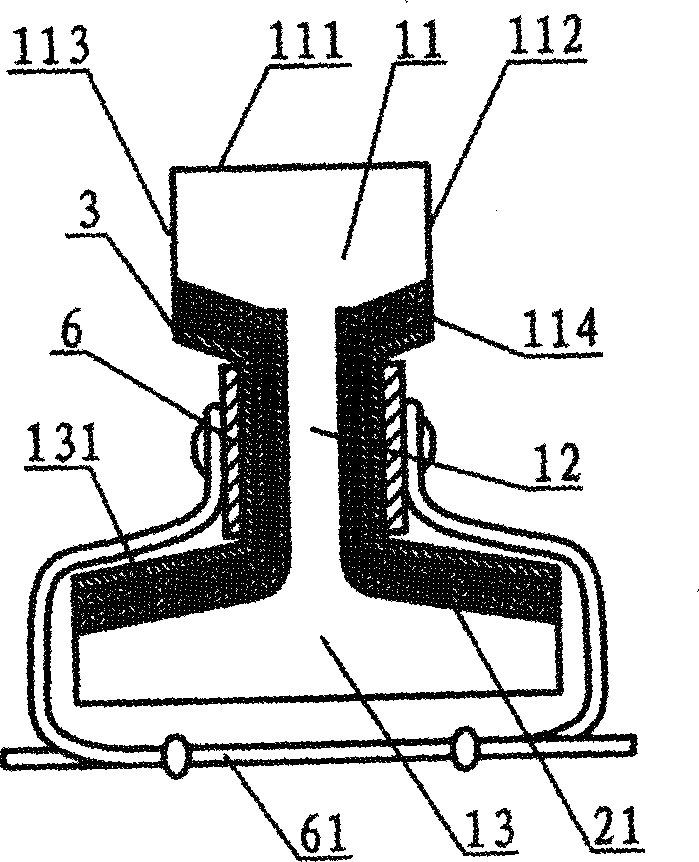

[0034] see image 3 , the difference from Example 2 is that the high damping material is two layers of high damping rubber, which is vulcanized together with the restraint plate in the factory to make a damping structure, which is tightly compressed by the clamping parts 6 arranged on both sides of the rail waist 12 on both sides of the track body. The clamping part 6 is a C-shaped hoop that wraps around the bottom of the rail between the rail ties, and it can also be an extension of the rail fastener spring to the rail waist, or a bolt that penetrates the rail waist.

[0035] Embodiments 1-3 can be implemented in factory production or on-site, but embodiment 3 is relatively more suitable for rapid on-site implementation. If it is produced in the factory, the restraint plate and the track body are directly vulcanized into one with high damping rubber, without clamping parts, and the vibration reduction effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com