Rotary disc spinning process and apparatus

A technology of spinning device and spinning method, which is applied in dry spinning, textile and papermaking, filament/thread forming, etc., and can solve the problems of low production efficiency, small demand and high price of raw materials in electrospinning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

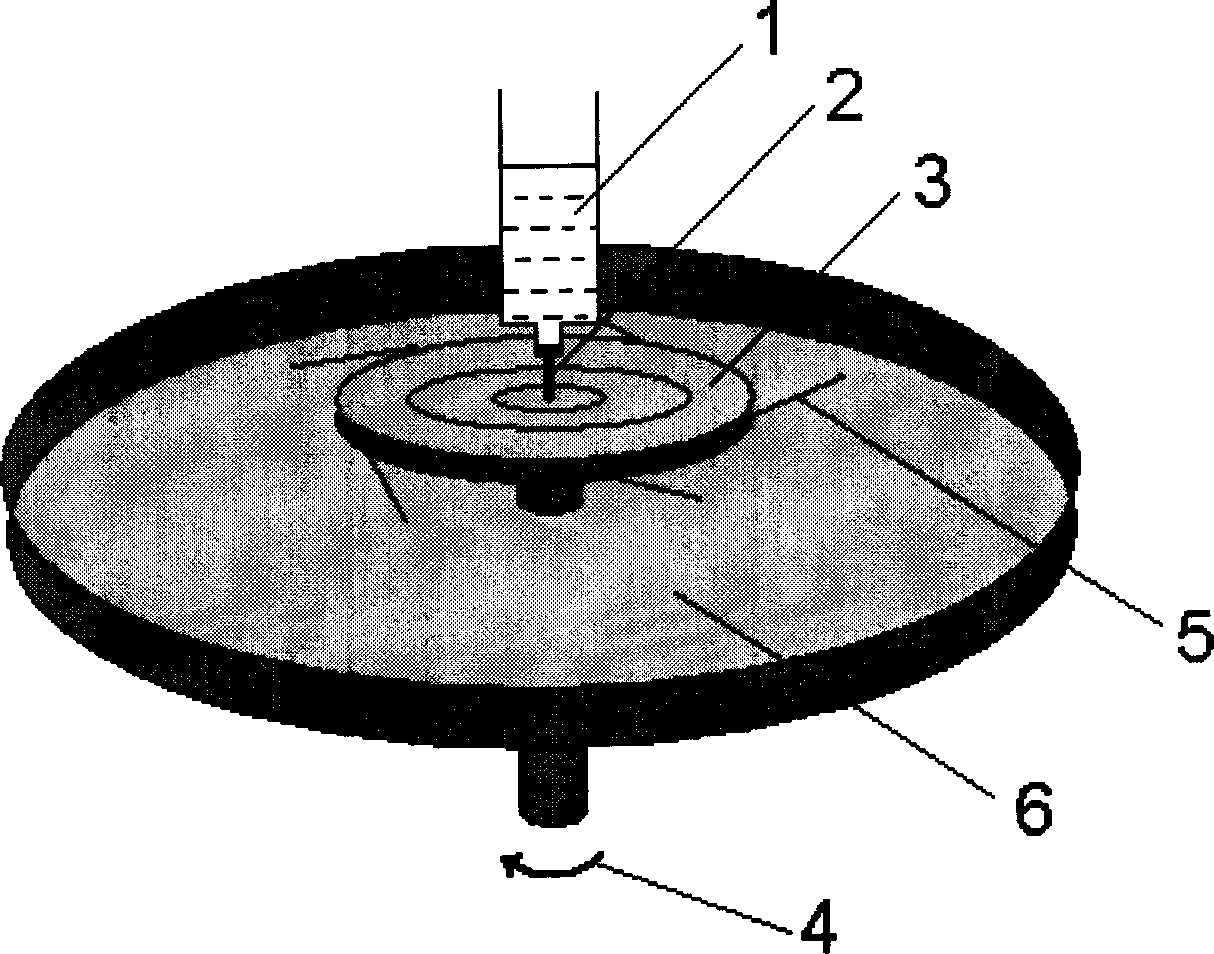

Method used

Image

Examples

Embodiment 1

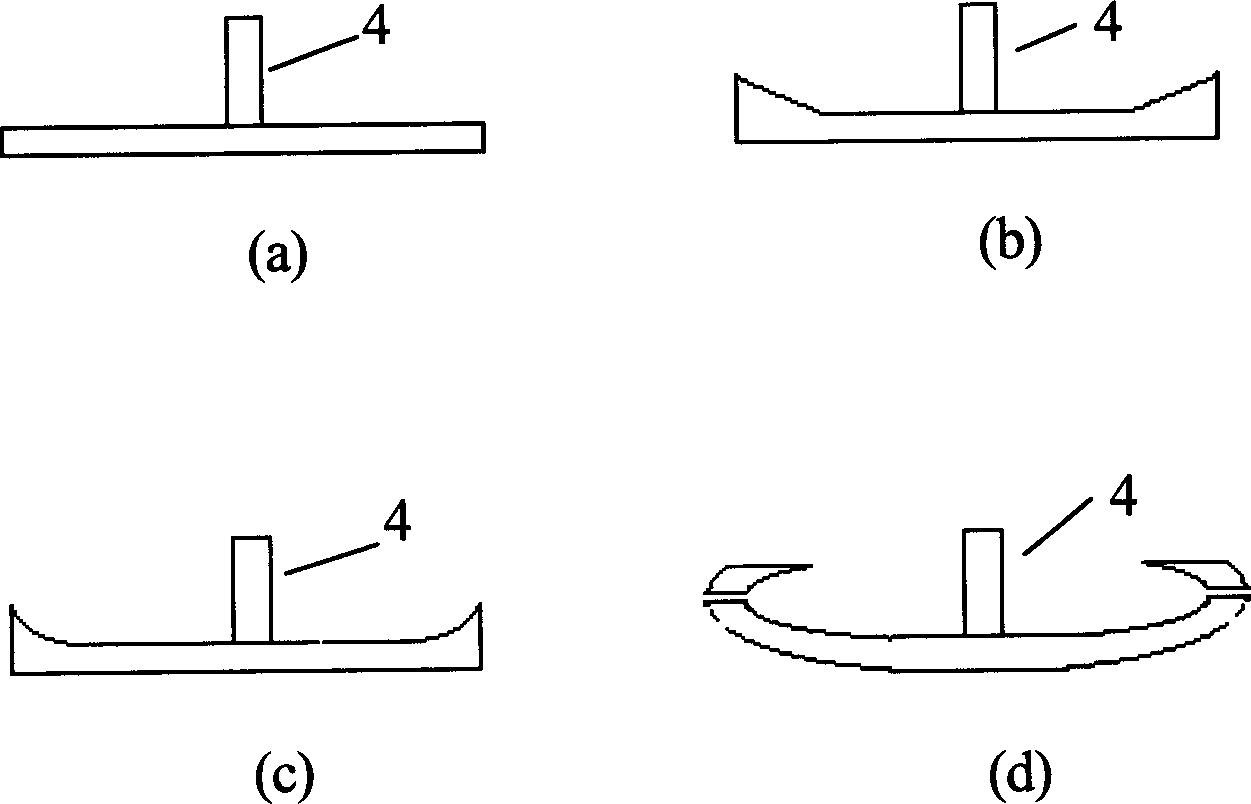

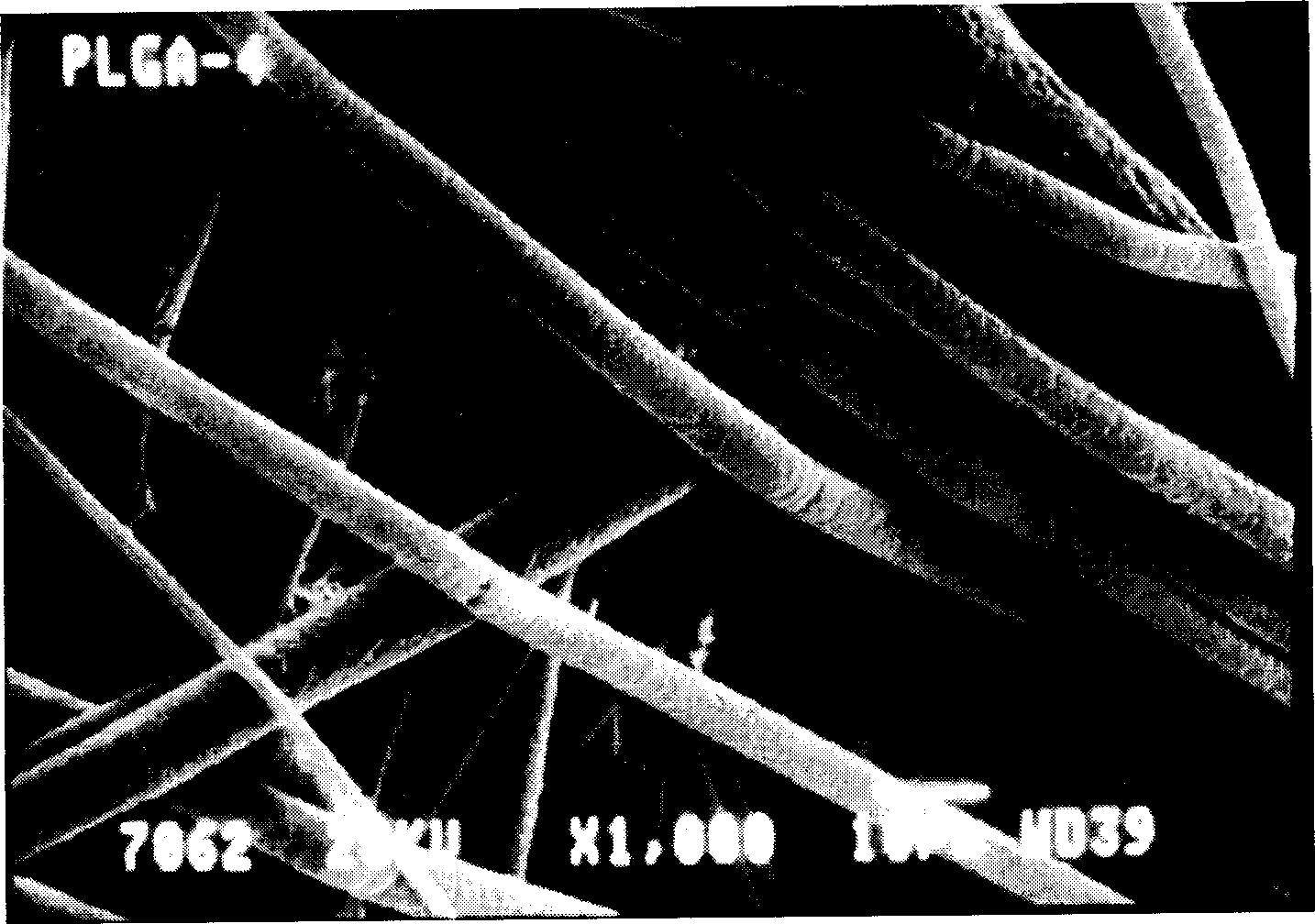

[0029] Embodiment 1. 7 g of the random copolymer PLGA of lactide and glycolide (wherein mass composition lactide 80%, glycolide 20%, viscosity-average molecular weight is 55,000) is dissolved in 30mL chloroform, ultrasonic vibration Make it fully dissolved. The solution was transferred to a 50mL syringe with an 18-gauge needle before spinning. The upper surface of the rotating disk of the spinning device is a horizontal plane (see figure 2 a), the diameter is 40mm, the spinning speed is adjustable in the range of 0-12000rpm, and can be displayed. First adjust the rotating speed of the rotating disk to 5000rpm, then manually press the plunger of the syringe to squeeze out the solution and continuously drop it to the center of the rotating disk. The fibrous receiver is a black circular piece of paper with a diameter of approximately 50 cm and a height approximately 10 cm lower than that of the rotating disc, which is stationary. A garden cylinder made of metal with a height ...

Embodiment 2

[0031] Example 2. Dissolve 1.5 g of L-polylactic acid PLLA (viscosity average molecular weight: 153,000) in a mixed solvent of 20 mL of chloroform and 10 mL of acetone, and ultrasonically vibrate to fully dissolve it. The solution was transferred to a 50mL syringe with an 18-gauge needle before spinning. Be used in the same spinning equipment of embodiment 1, the rotating disk is a conical surface rotating disk (see figure 2 b), the diameter of the rotating disk is 40mm, and the rotation speed is 8000rpm. Scanning electron micrographs of the obtained fibers are shown in Figure 4 .

Embodiment 3

[0032] Embodiment 3. spinning solution and spinning equipment are the same as embodiment 1, and the rotating disk is a curved surface rotating disk (see figure 2 c), the diameter of the rotating disk is 40mm, and the rotation speed is 6000rpm. Scanning electron micrographs of the obtained fibers are shown in Figure 5 , the sampling locations of the two pictures are different

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com