Temperature determining system and method for drying cokery

A detection system and detection method technology, applied in the direction of thermometers, coke ovens, furnace safety devices, etc., can solve the problems that the temperature change value is smaller than the thermocouple accuracy deviation, the temperature change value is smaller than the atmospheric temperature change value in the same period, etc., to achieve greater The effect of frequency, labor reduction, and precision improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

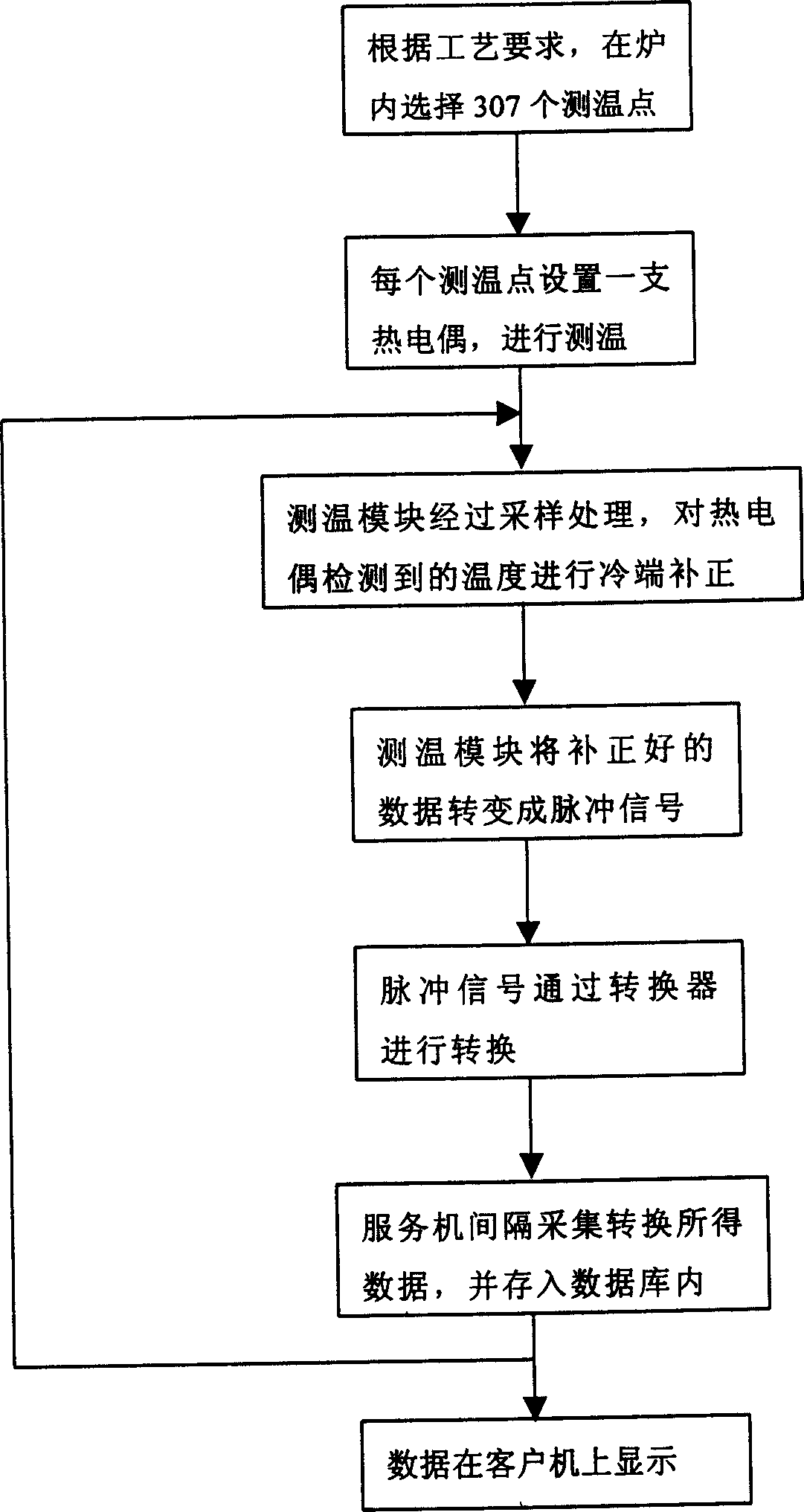

[0019] The following is based on figure 1 , figure 2 and image 3 A preferred embodiment of the present invention is given and described in detail, so that the structural features, functions and characteristics of the present invention can be better understood.

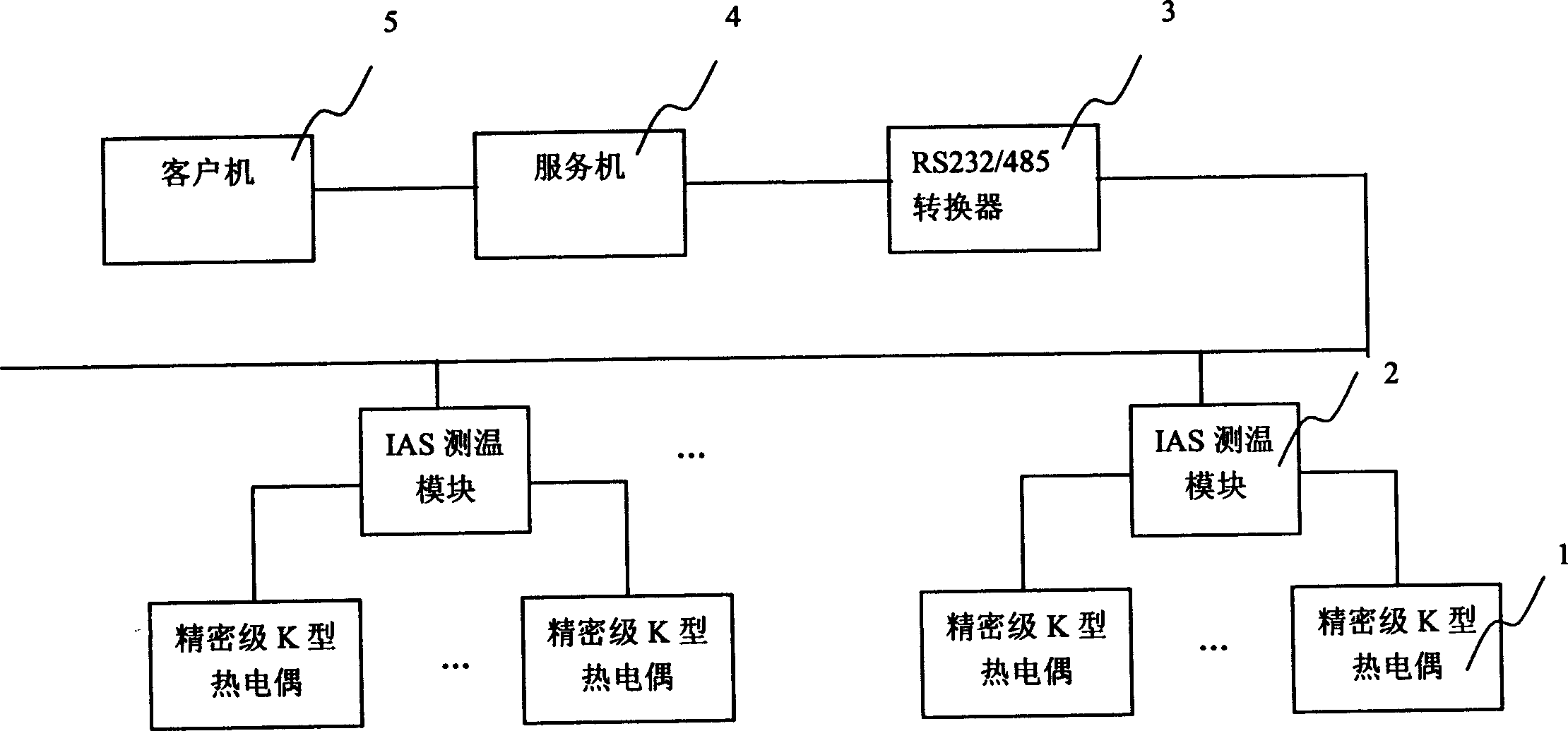

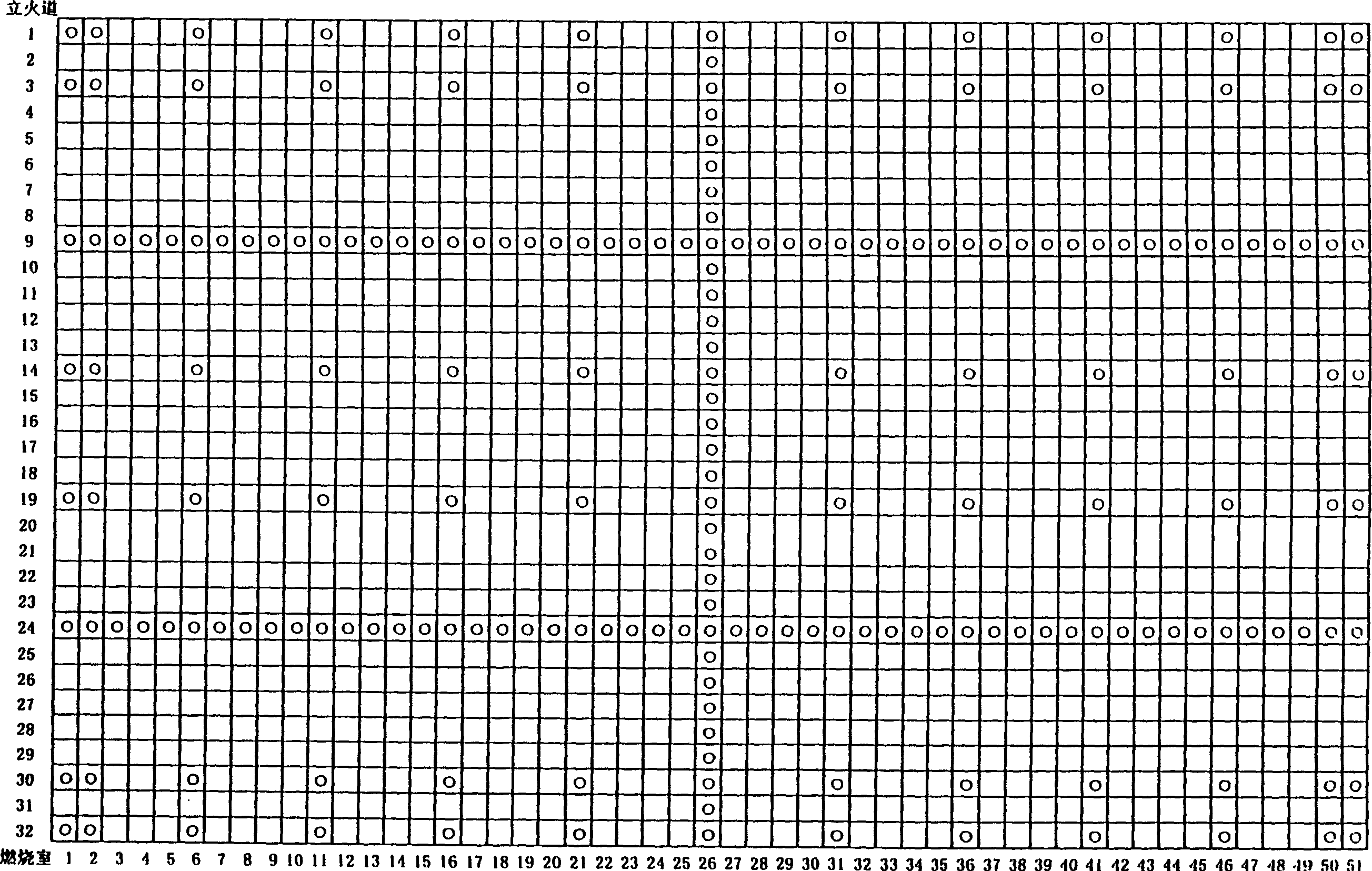

[0020] see figure 1 and figure 2 , as shown in the figure, the temperature detection system of the coke oven oven in this embodiment includes a precision grade K-type thermocouple 1, an IAS temperature measurement module 2, an RS 232 / 485 converter 3, a server machine 4, and a client machine connected in sequence 5. According to the requirements of the oven, 307 temperature detection points are arranged, and a precision K-type thermocouple is set at each temperature measurement point, and every 4 to 7 precision K-type thermocouples are connected with an IAS temperature measurement module 2 . The IAS temperature measurement module 2 undergoes sampling processing to correct the temperature detected by the precisio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com