Method for producing electric connecter

A manufacturing method and technology of electrical connectors, applied in the direction of contact manufacturing, contact box/base manufacturing, contact assembly/disassembly, etc., can solve the problem of high cutting resistance, reduce product defect rate, reduce production efficiency, etc. problem, to achieve the effect of reducing cutting resistance, reducing the probability of burrs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

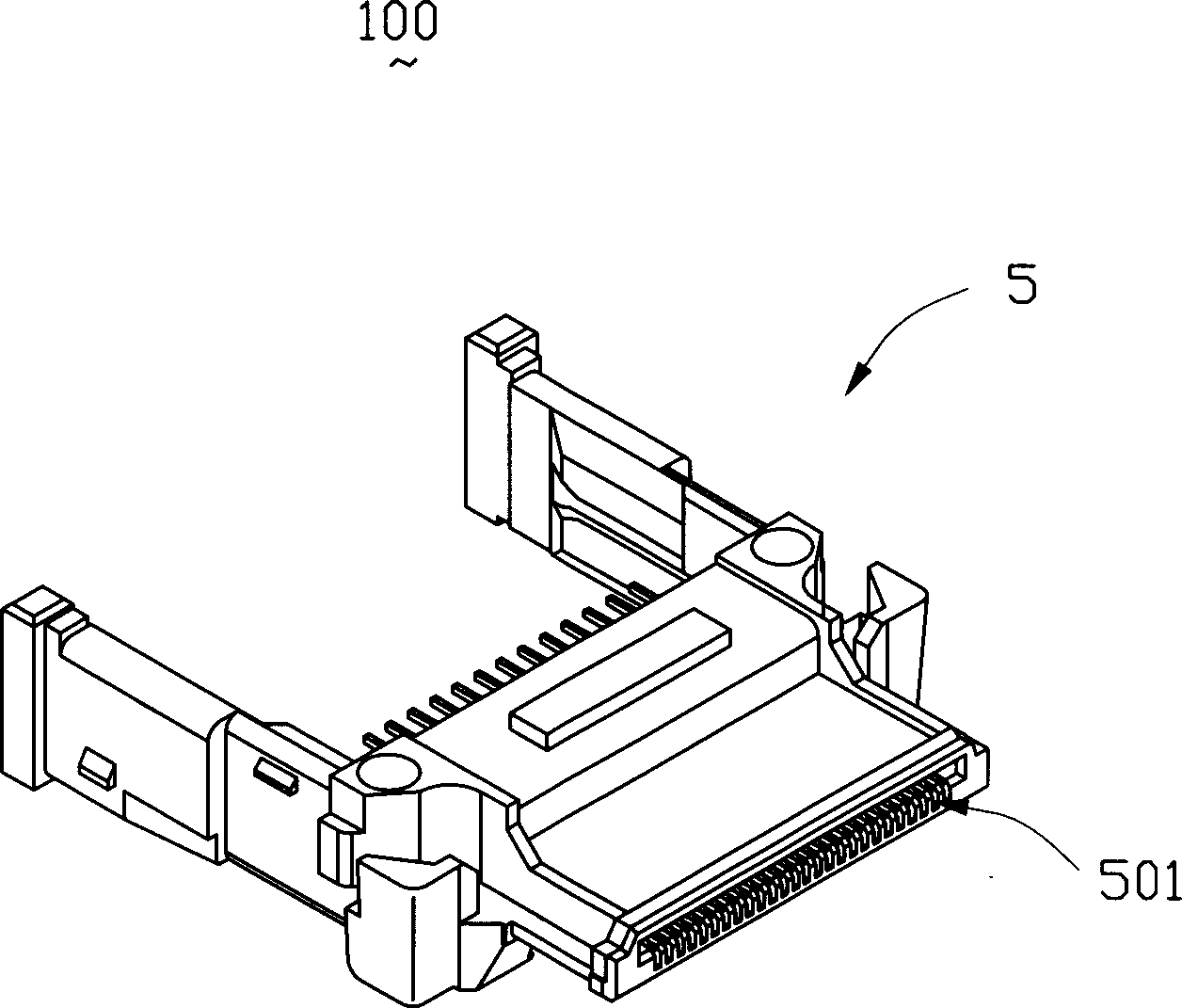

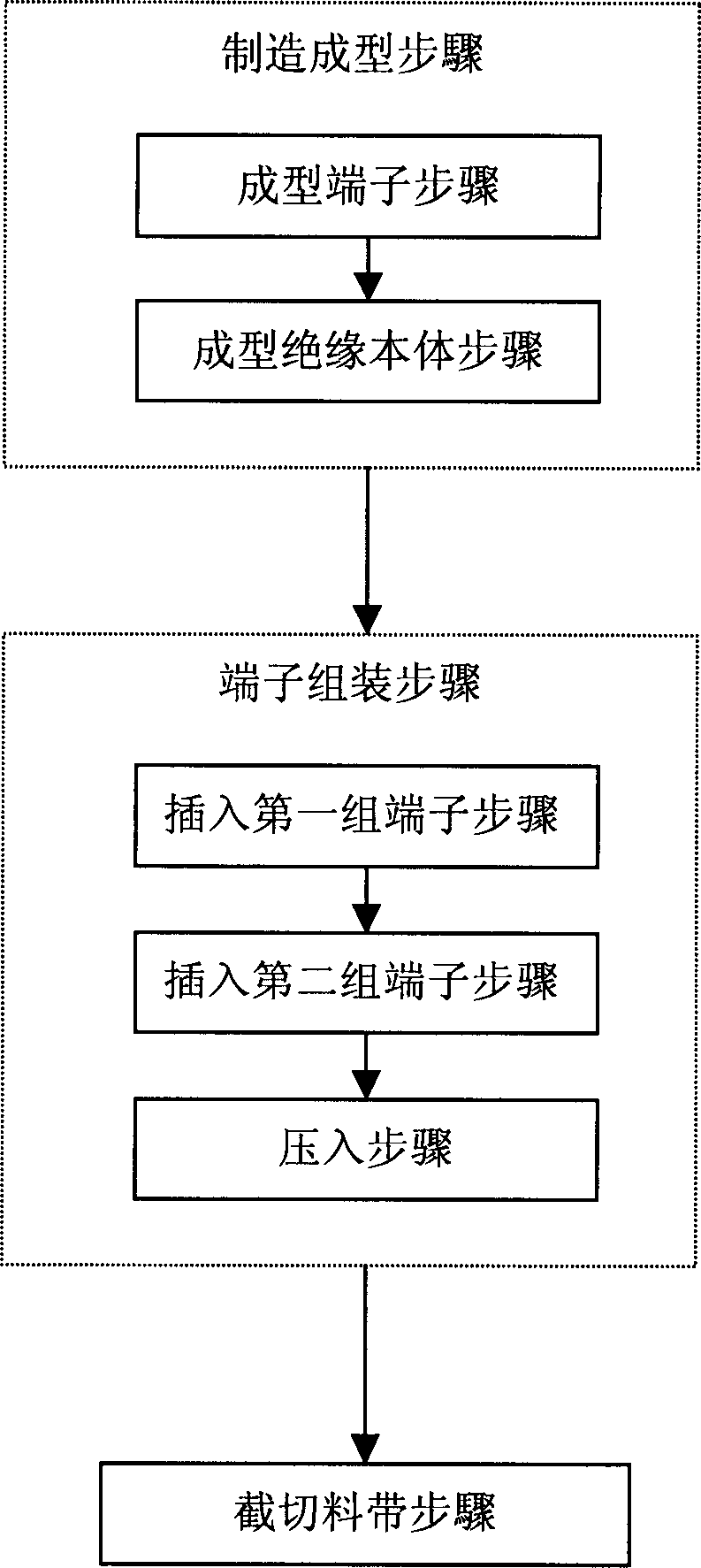

[0013] The electrical connector 100 manufactured according to the present invention includes an insulating body 5 and terminals, wherein the terminals are accommodated in the terminal receiving groove 501 of the insulating body 5. The manufacturing method of the connector 100 includes manufacturing molding steps, terminal assembling steps and cutting strips Step, in this embodiment, the terminals are divided into four groups and inserted into the terminal accommodating groove 501, because the third and fourth groups of terminals are the same as the first and second group of terminals in terms of structure and insertion sequence, the following only use the first and the second group of terminals The second group of terminals is used as an example for introduction.

[0014] see figure 1 , image 3 with Figure 5 As shown, the manufacturing molding step includes the following steps:

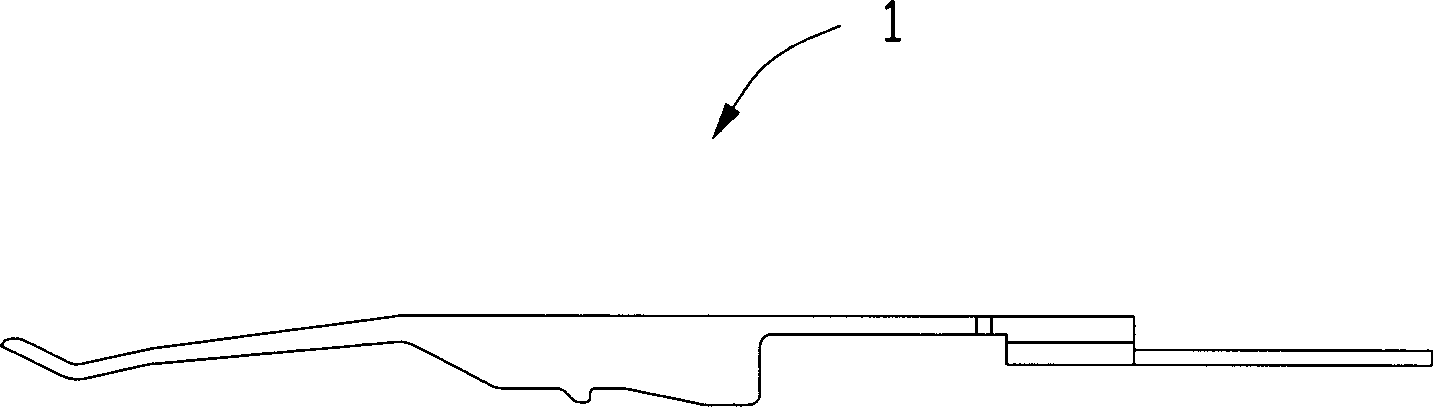

[0015] Step 1: Forming the terminal, which is to make a number of first

[0016] The fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com