Lifting mechanism for casting crane

A hoisting mechanism and crane technology, which is applied to cranes, clockwork mechanisms, walking bridge cranes, etc., can solve the problem that it is difficult to meet the technological requirements of steel mills, the left and right limit size of the spreader is increased, and the width of the small frame is large. and other problems, to achieve the effect of reducing the left and right limit size, reducing annealing treatment and overall processing, and reducing the height of the workshop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Typical embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

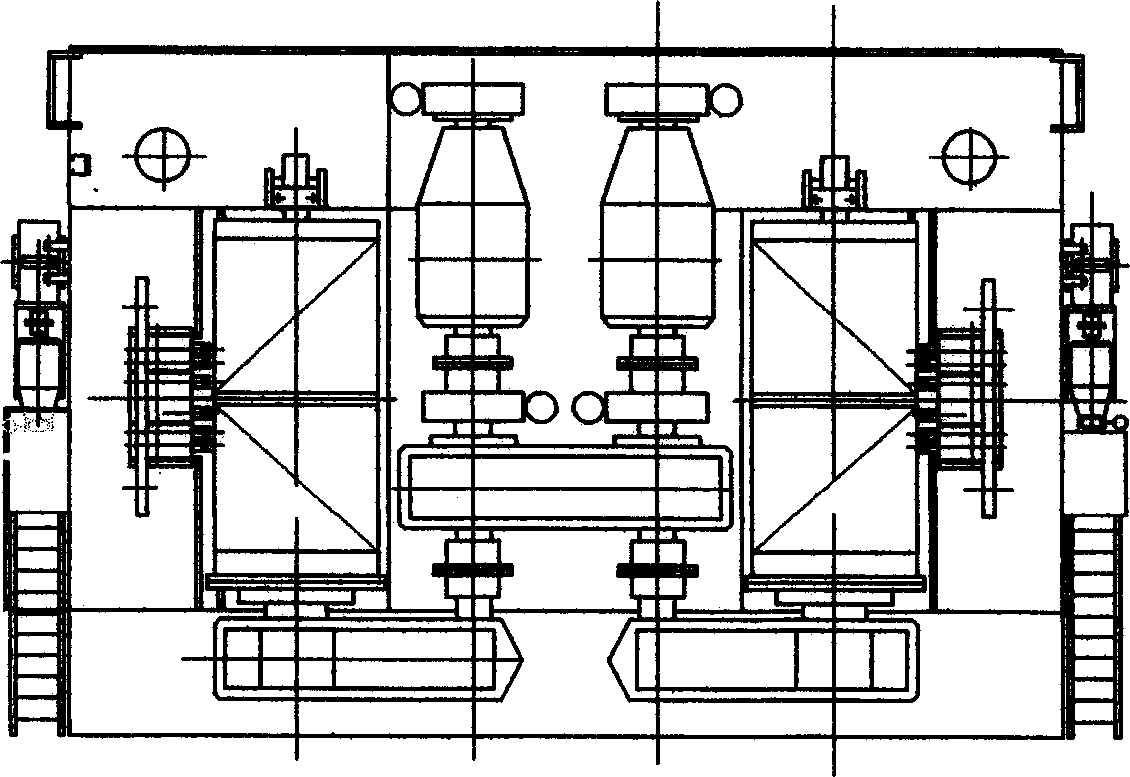

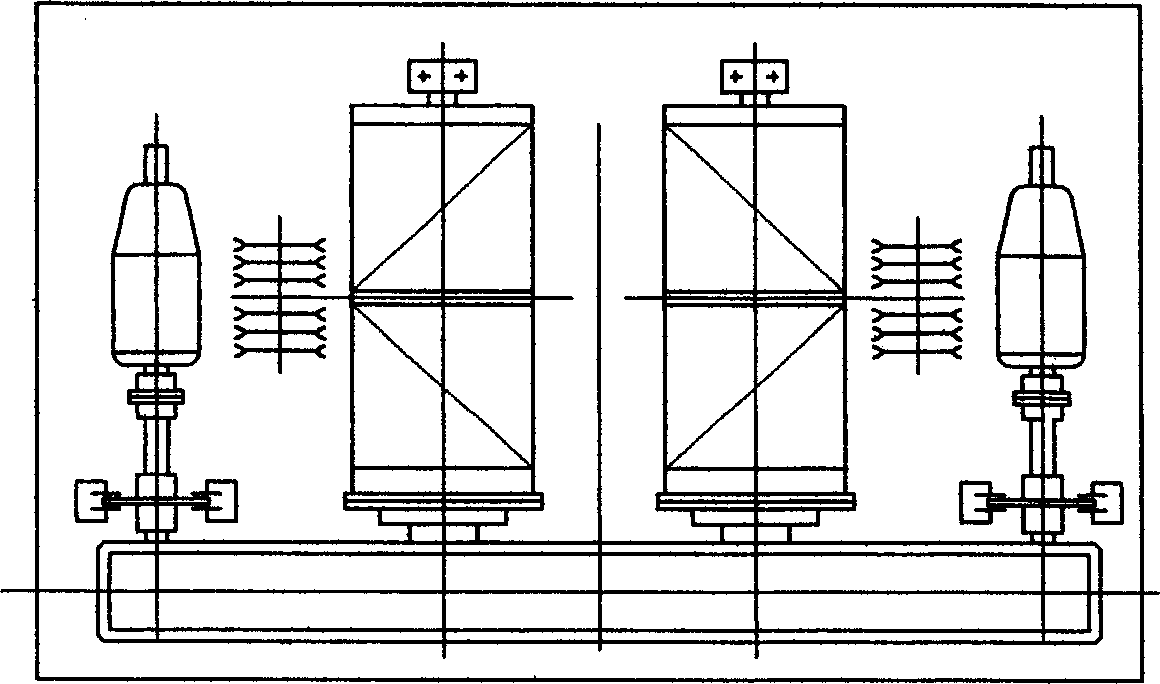

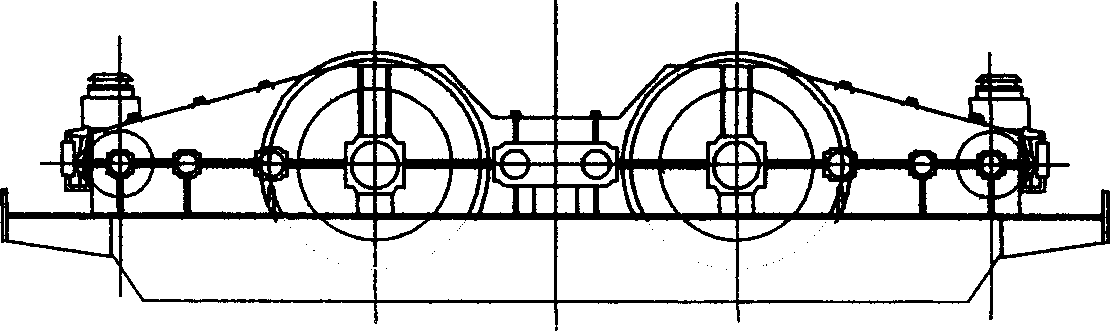

[0020] Figure 4 A hoisting mechanism of a foundry crane is shown. Double drive system consisting of double motors 1, half gear coupling 2, floating shaft 3, half gear coupling with brake disc 5, brake system 4, reducer 9, etc. installed on the trolley frame 10 platform device, the reel device 7, the coupling 8 on the two output shafts of the reel device and the reducer, and the two fixed pulley blocks 6 arranged correspondingly outside the reel device. On each high-speed shaft of the reducer, two disc brakes 4 are respectively installed. The speed reducer is a whole, and a synchronous connection device 11 is arranged between the high-speed gears of the two input shafts. The connecting device can use an idler, and use the idler to connect two sets of driving devices to drive the double reels synchronously; or install a planetary package as a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap