Volatile organic waste water concentrating and treating system

A volatile organic, volatile organic compound technology, applied in the field of volatile organic wastewater concentration treatment system, can solve the problem of large consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

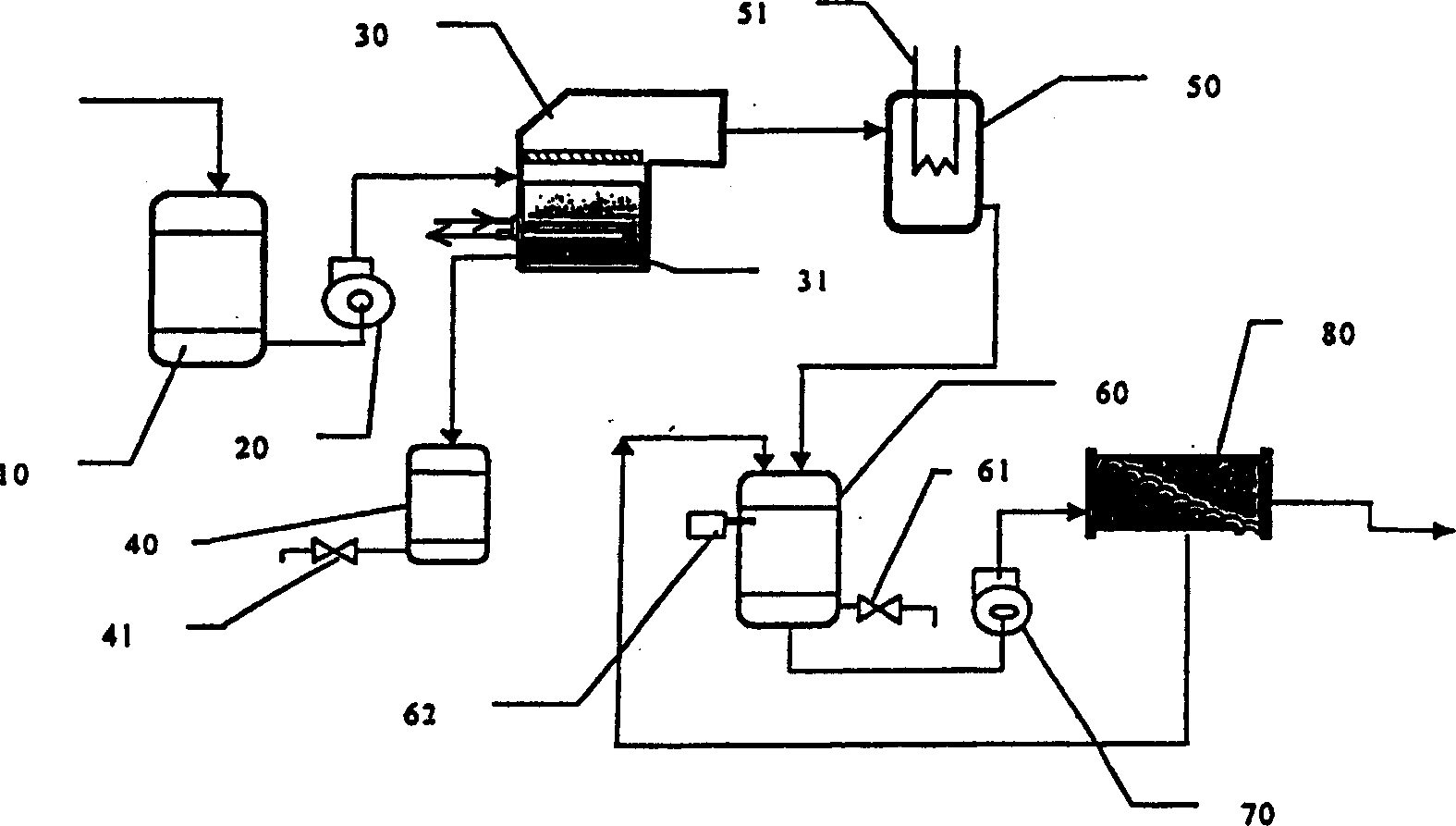

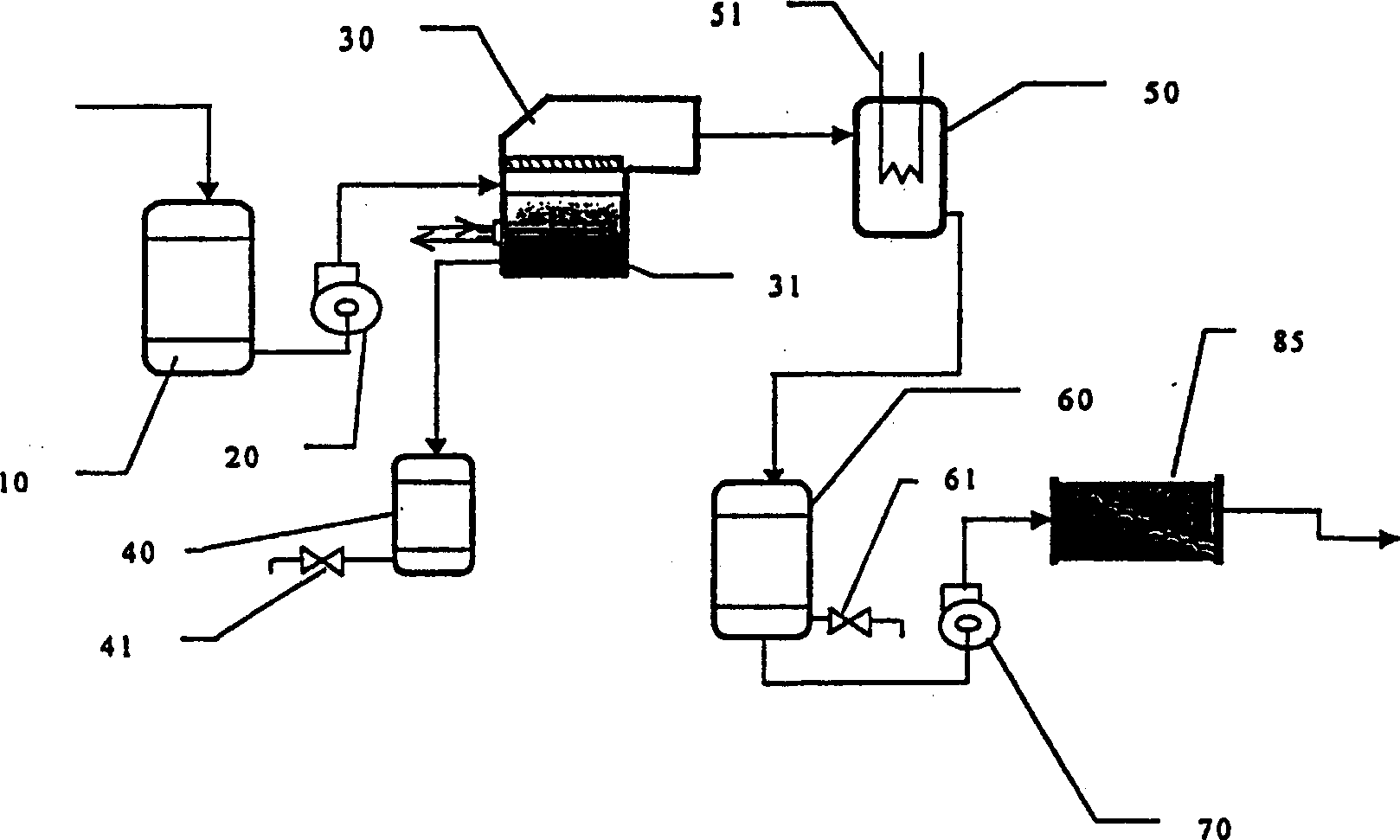

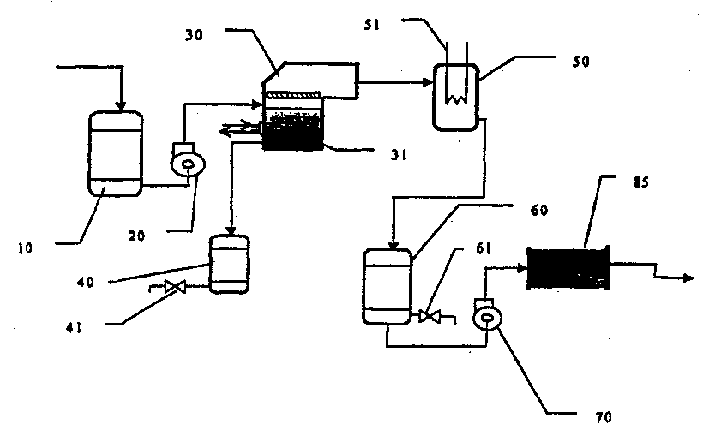

[0026] see figure 1 , is a schematic diagram of an embodiment of a volatile organic wastewater concentration treatment system. The volatile organic waste water produced by the factory is introduced into an inlet water storage tank 10, which is used as a temporary storage container for the waste water, and then through a waste water inlet water pump 20, the waste water is pressurized from the water inlet storage tank into an evaporator 30, The evaporator 30 is equipped with a heater 31 to heat the waste water. The temperature is set at a slightly higher boiling point of water to evaporate the water and low-boiling substances in it. The remaining high-boiling volatile organic substances in the evaporator 30 are introduced into a concentrated waste The liquid storage tank 40, the concentrated waste liquid storage tank 40 and the waste liquid used to store the evaporator 30 with a higher boiling point than water, after the storage is full, it is controlled by the discharge valve 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com