Crystal back grinding water, diamond wire slicing water and sludge recycling system

A diamond wire and slicing technology, which is applied in the fields of crystal back grinding water, diamond wire slicing water and sludge recycling system, can solve the problems of high cost and waste of resources, so as to reduce treatment costs, water consumption and waste water. Effects of processing fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

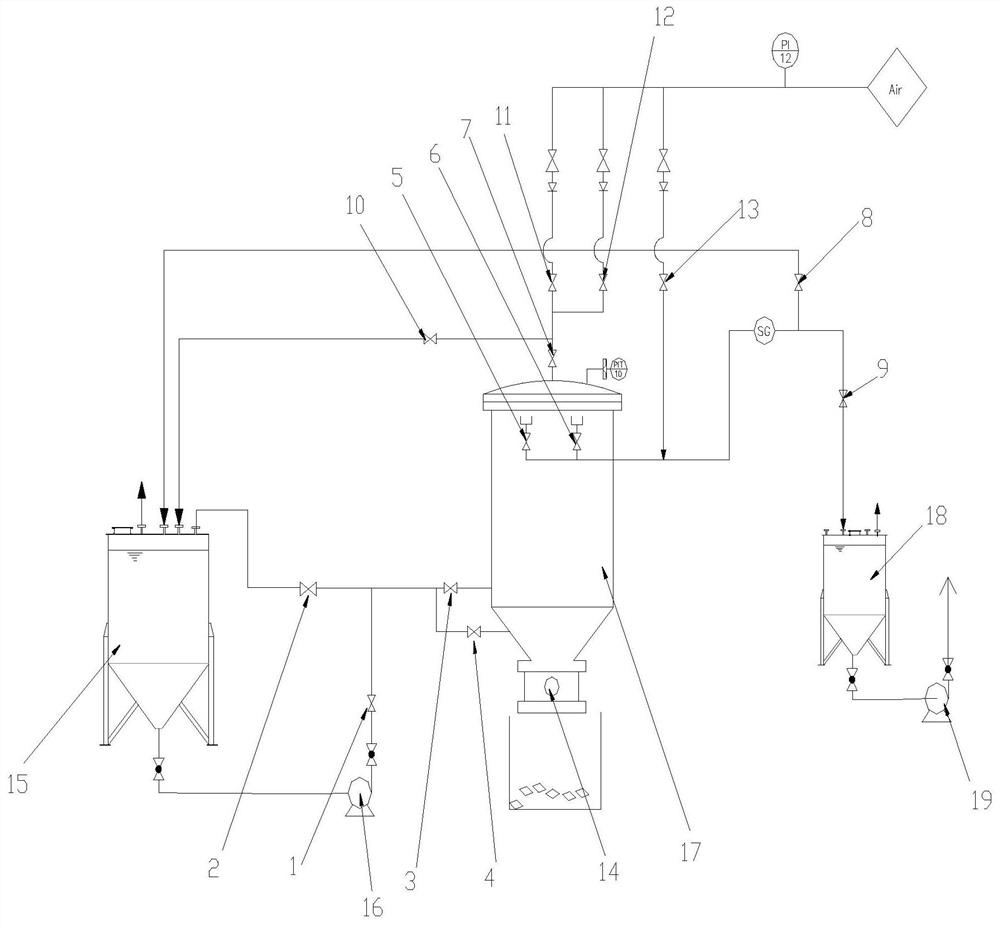

[0016] Such as figure 1 The shown crystal back grinding water, diamond wire slicing water and sludge recovery and reuse system include a pipeline system, and the pipeline system is sequentially provided with a waste liquid tank 15 for placing waste liquid according to the flow direction of the liquid. In the filter 17 for filtering waste liquid and the clear liquid tank 18 for storing the filtered clear liquid, a filter pump 16 is arranged between the waste liquid tank 15 and the filter 17 on the pipeline system, and the pipeline system A clear liquid pump is arranged on the side of the clear liquid tank 18 away from the filter 17 on the system. 19. The pipeline system is provided with a filter assembly, a pre-filter assembly, a drain assembly, a filter cloth cleaning assembly, a pressure relief assembly, a filter cake drying assembly and a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com