Cyclone-wet type dcompound dust collector with fiber grid mesh

A technology of cyclone dust collector and fiber grid, which is applied in the direction of combination device, chemical instrument and method, and separation of dispersed particles, can solve the problems that cannot meet the requirements of smoke emission indicators, the influence of dust particle size and density, and the influence of dust removal efficiency, etc., to achieve Simple structure, high dust removal efficiency and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

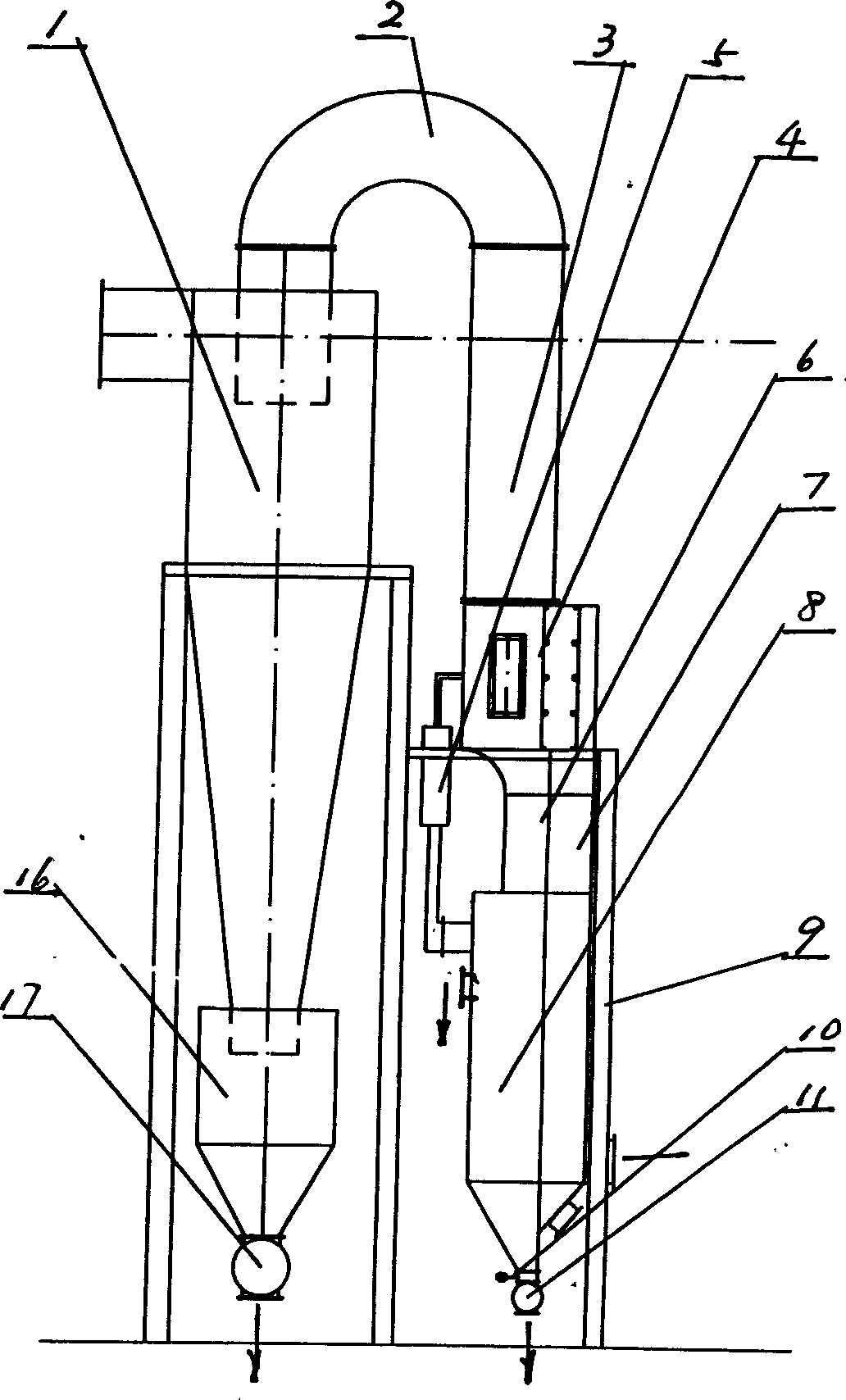

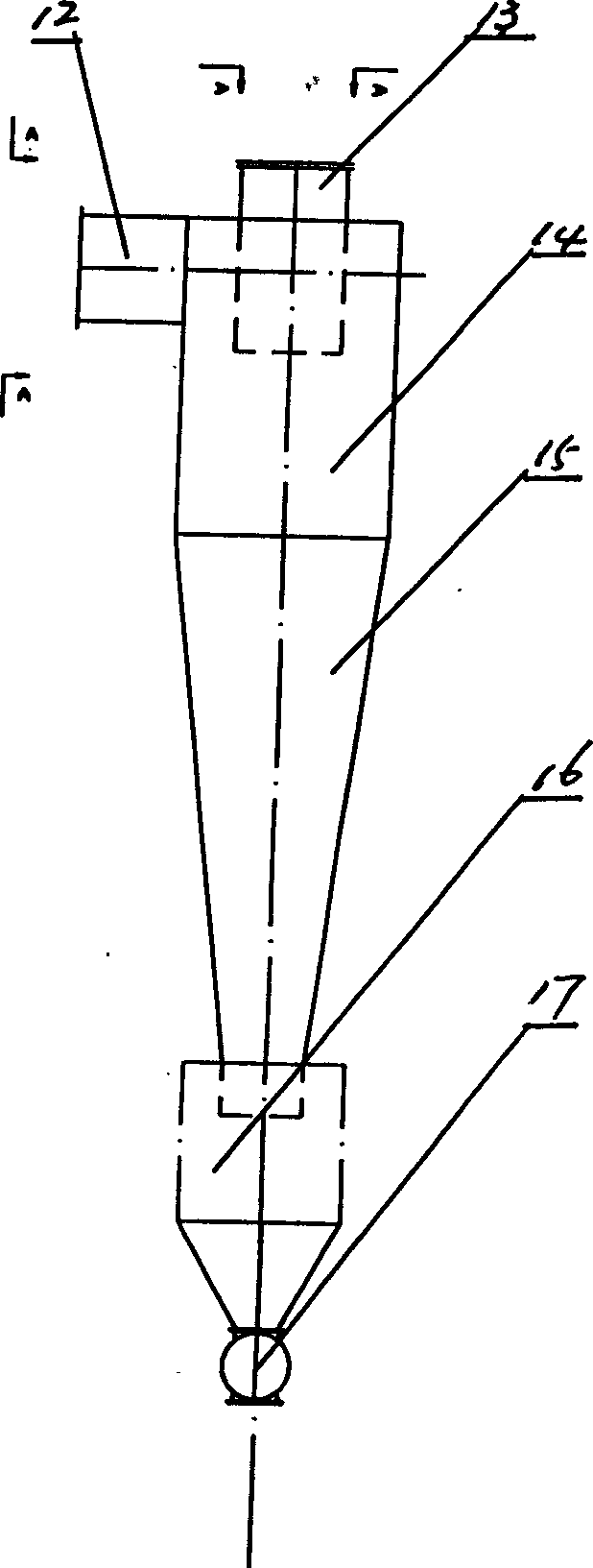

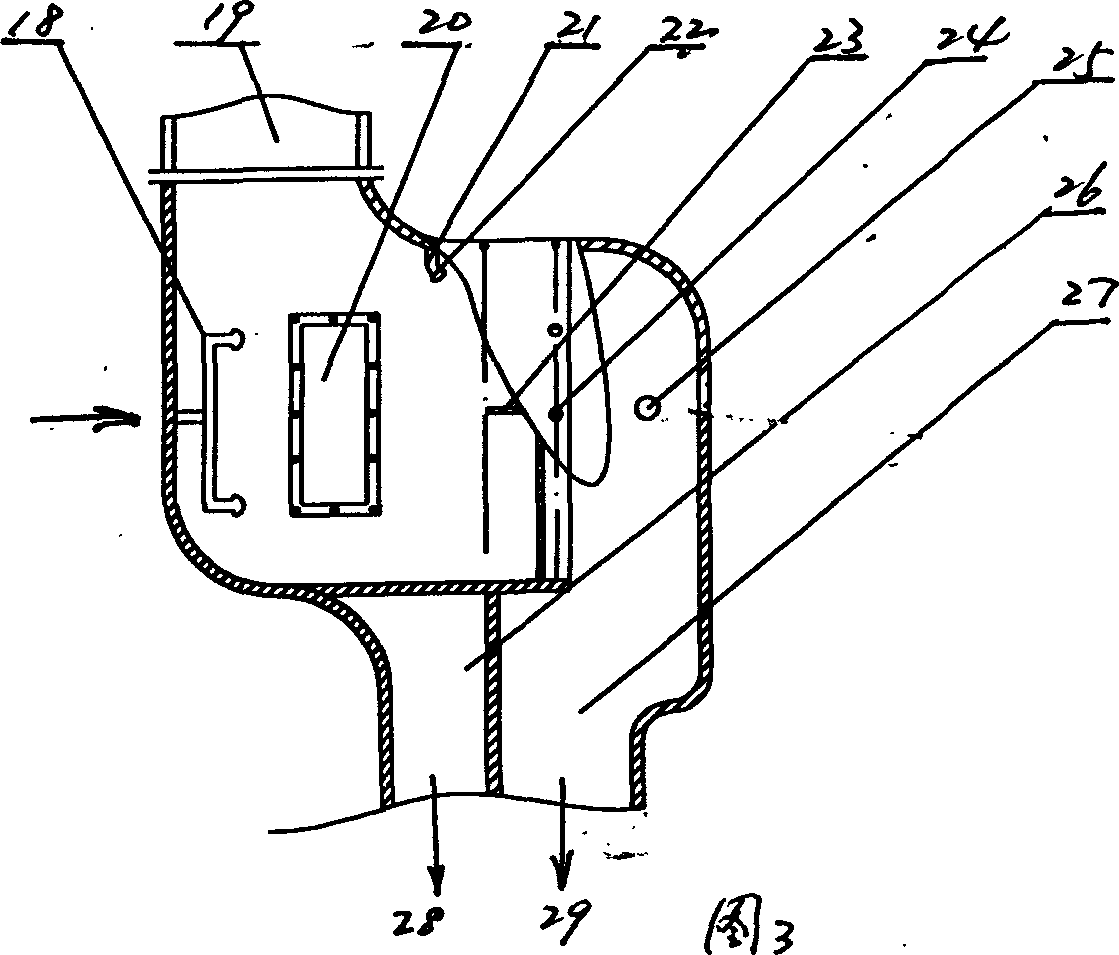

[0016] The structure and working principle of the present invention are described in detail in conjunction with accompanying drawings.

[0017] From figure 1 It is known that the side of the cyclone dust collector 1 is the air inlet, and the air inlet needs to be purified. On the one hand, the dry ash is discharged from the ash hopper 16 and the rotary ash discharge valve 17 under the cyclone dust collector, and the cyclone dust collector is connected in series as an elbow 2. Connect the wet fiber grid dust collector 4 through the variable diameter pipe 3, and connect the vertical sedimentation tank 8 with the drain pipe 6 and exhaust pipe 7 below. The ash discharge valve 11 below the box is discharged. The upper part of the cyclone dust collector 1 is an exhaust pipe 13, the lower part is a cylinder 14, the lower part of the cylinder 14 is a cone 15, and the bottom is an ash hopper 16 and a rotary ash discharge valve 17; the other part connected in series with the cyclone du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com