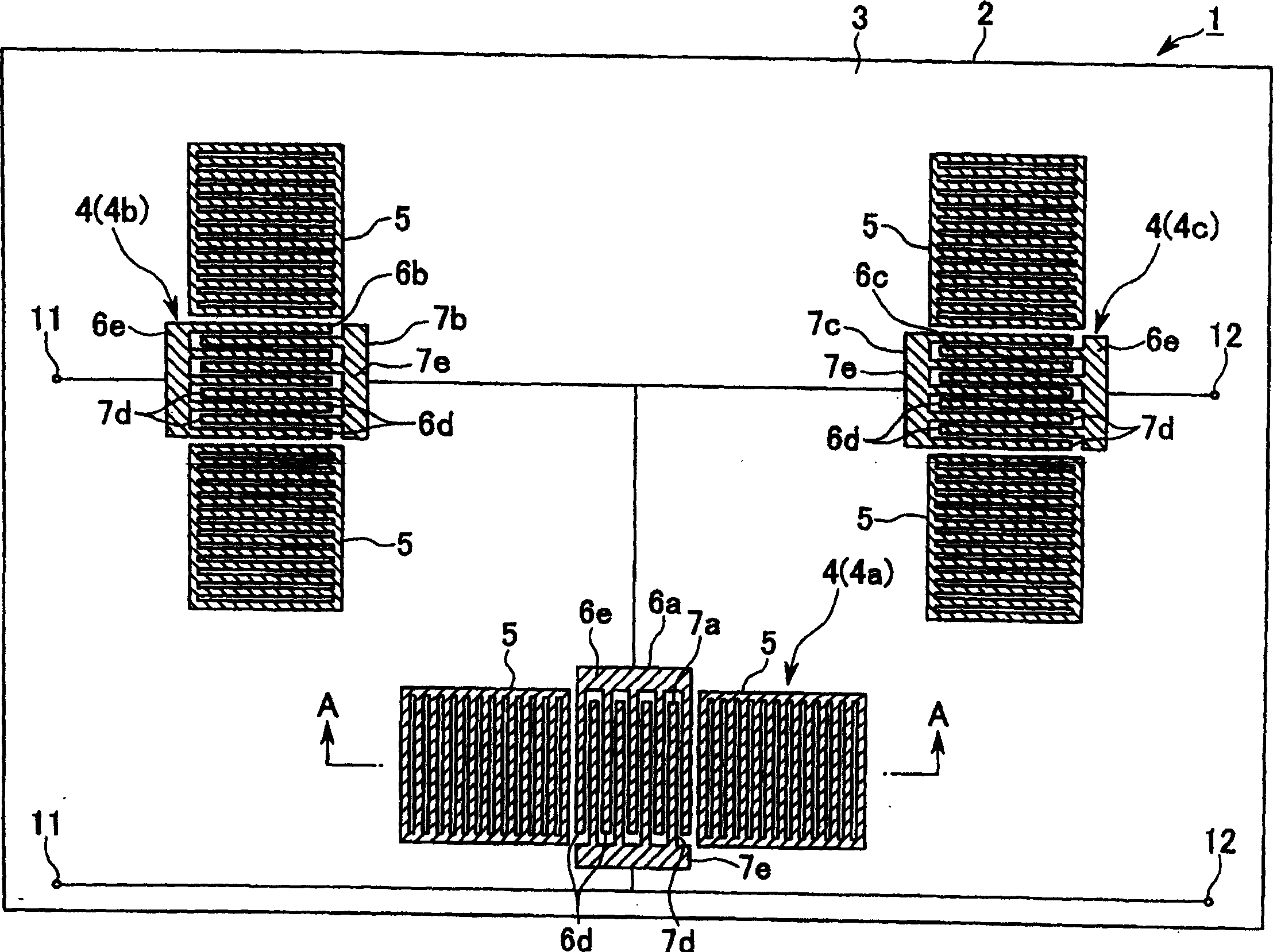

Ladder type SAW filter and its mfg. method

A manufacturing method and filter technology, applied in the direction of electrical components, impedance networks, etc., can solve the problems of different propagation speeds of surface elastic waves, large differences in propagation speeds of surface elastic waves, and reduction of broadband characteristics of filtering characteristics, so as to reduce propagation The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

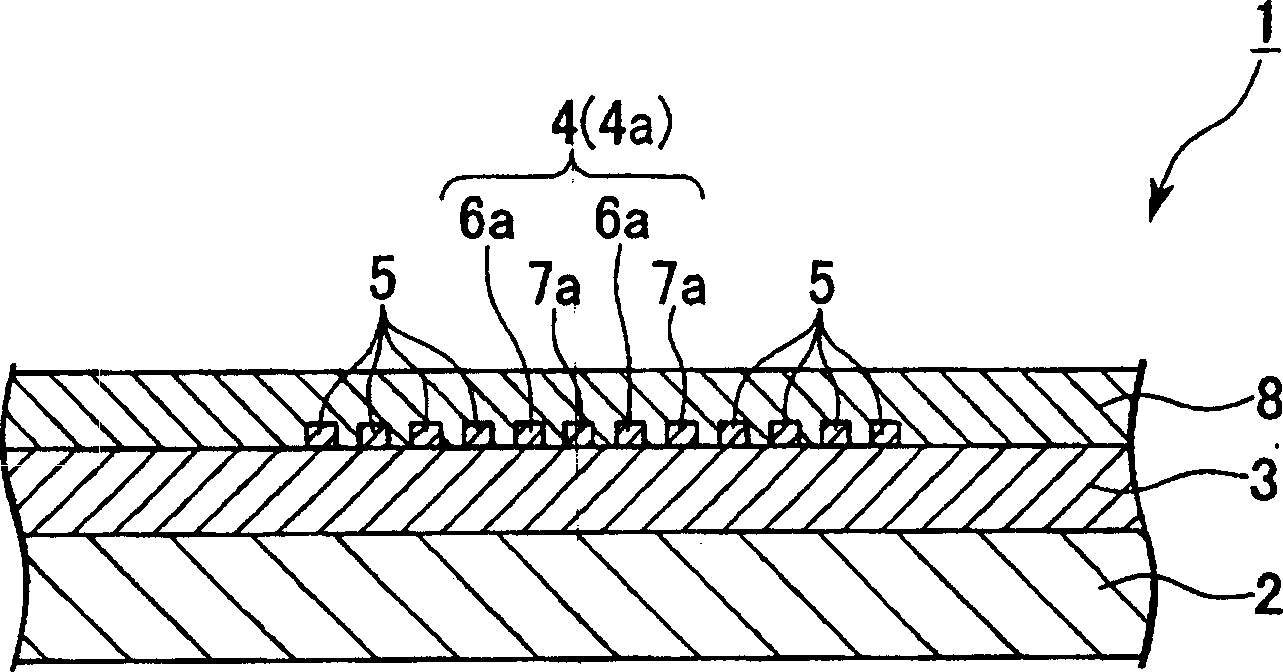

Method used

Image

Examples

Embodiment 1

[0074] (Example 1) "Experimental example 1: Case of A-side sapphire substrate"

[0075] First, a disk-shaped substrate with a diameter of 100 mm exposed on the A surface is prepared in advance, and the substrate is placed in a chamber (chamber) of a sputtering device, and the chamber is temporarily held at 10 -6 ~10 -8 After the vacuum environment of Pa, argon gas was introduced to make the pressure 4-6 Pa.

[0076] Next, with the substrate kept at 350° C., sputtered particles were ejected from a ZnO target body with a diameter of 300 mm by a high-frequency sputtering method and laminated on the substrate. A high frequency of 13.65 MHz and 1.0 kW is applied to the target body. In addition, the incident angle of the sputtered particles to the substrate was set at 90° to the substrate surface. At this time, it is preferable to apply an RF bias voltage of about 10 W also to the substrate side.

[0077] In this way, a piezoelectric layer made of ZnO with a thickness of 0.8 μm wa...

experiment example 2

[0081] Such as Figure 4 As shown, it can be seen that the propagation velocity of the surface elastic wave is in the range of 4700 to 1800 (arbitrary unit) in any direction, and is constant in any direction. "Experimental example 2: Case of R-plane sapphire substrate"

[0082] Prepare a disk-shaped substrate with a diameter of 100 mm that exposes the R surface in advance, and set the substrate in the container of the sputtering device, and temporarily hold the container at 10 -6 ~10 -8 After the vacuum atmosphere of Pa, argon gas was introduced to make the pressure 0.2 to 0.3 Pa.

[0083] Next, with the substrate kept at 300°C, while applying an RF bias voltage with a frequency of 40.68 Hz to the substrate, sputtered particles were shot out from a ZnO target with a diameter of 300 mm by the high-frequency sputtering method, and deposited on the substrate. on the substrate. For the high frequency applied to the target and the substrate, the target frequency was 13.65 Hz, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com