Bent tube type heater for natural gas

A bent tube heater technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of complex induction heating equipment, inconvenient portability, and high cost, and achieve the effects of easy operation, convenient shipment, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

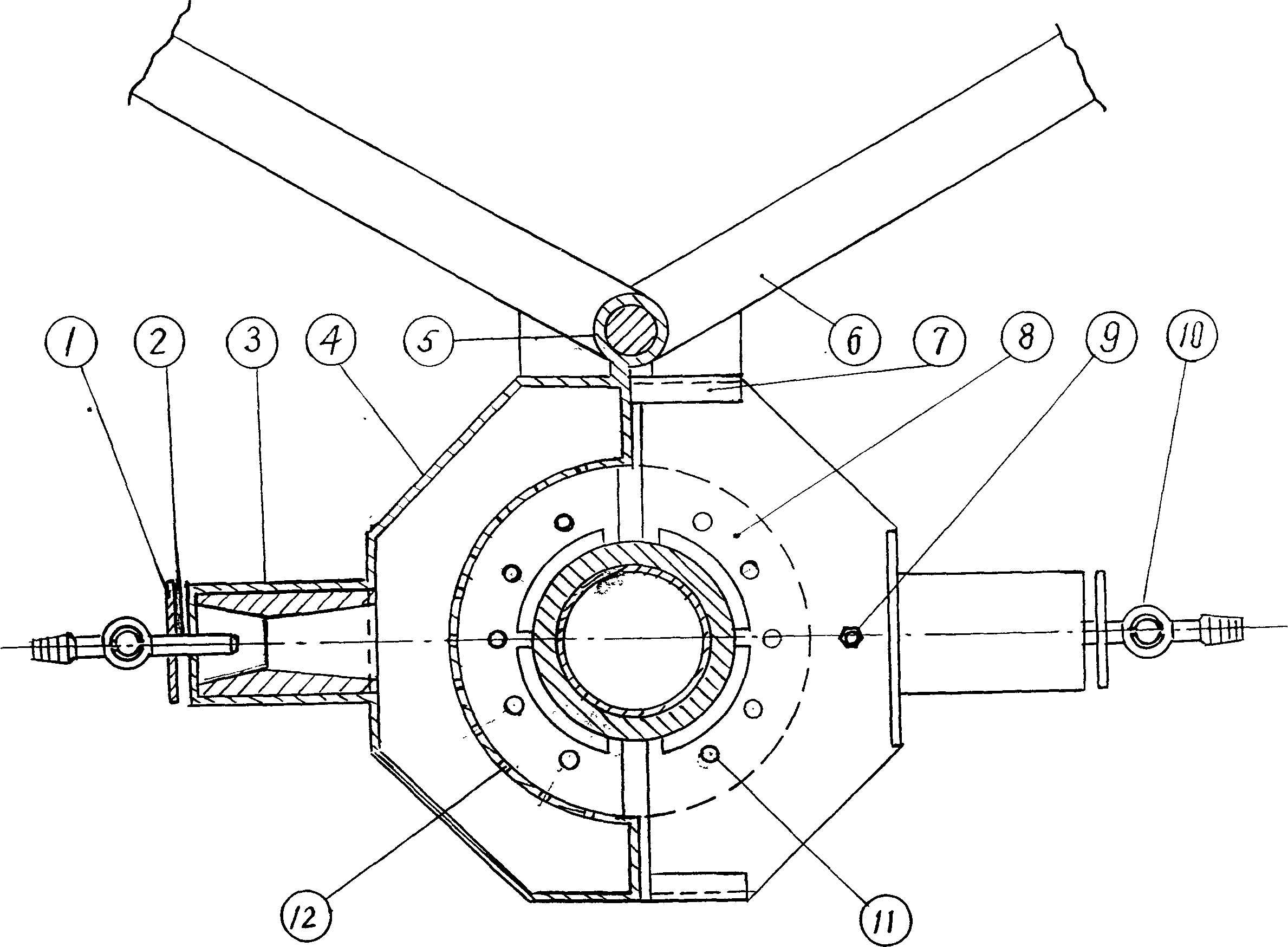

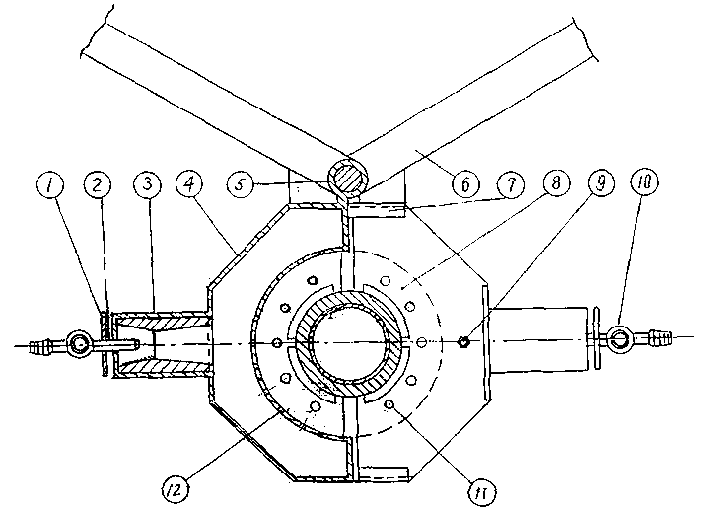

[0009] In the figure, elbow heater 1 is an air-regulating spiral piece, 2 is a nozzle, 3 is an outer nozzle, 4 is a burner, 5 is a hinge, 6 is a control handle, 7 is a guide block, and 8 is a positioning clamp. 10 is a switch, 11 is a waste gas discharge hole, and 12 is a flame injection hole.

[0010] As shown in the figure, the outer profile is a polygonal burner 4 with a thickness of about 40 mm, the outer profile is (40-60) mm from the inner wall, and the inner wall radius is 100 mm. The inner wall is provided with fire spray holes 12 with a diameter of 2mm, and the fire spray holes are evenly distributed and arranged, and the liquefied gas is introduced through the rubber hose, and the air pressure is adjusted to 0.5kgf / cm 2 . Inject into the burner 4 cavity through the nozzle 2, adjust the air and adjust the spiral piece 1, inhale an appropriate amount of air and mix it with fuel, use it to heat a shape memory alloy pipe joint with a thickness of 2mm, a length of 50mm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com