Method for producing cycloheximide and technology thereof

A production method, the technology of cyclohexyl imine, applied in the direction of organic chemistry, etc., can solve the problems of not producing cyclohexyl imine, etc., and achieve the effect of low production cost, advanced technology and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

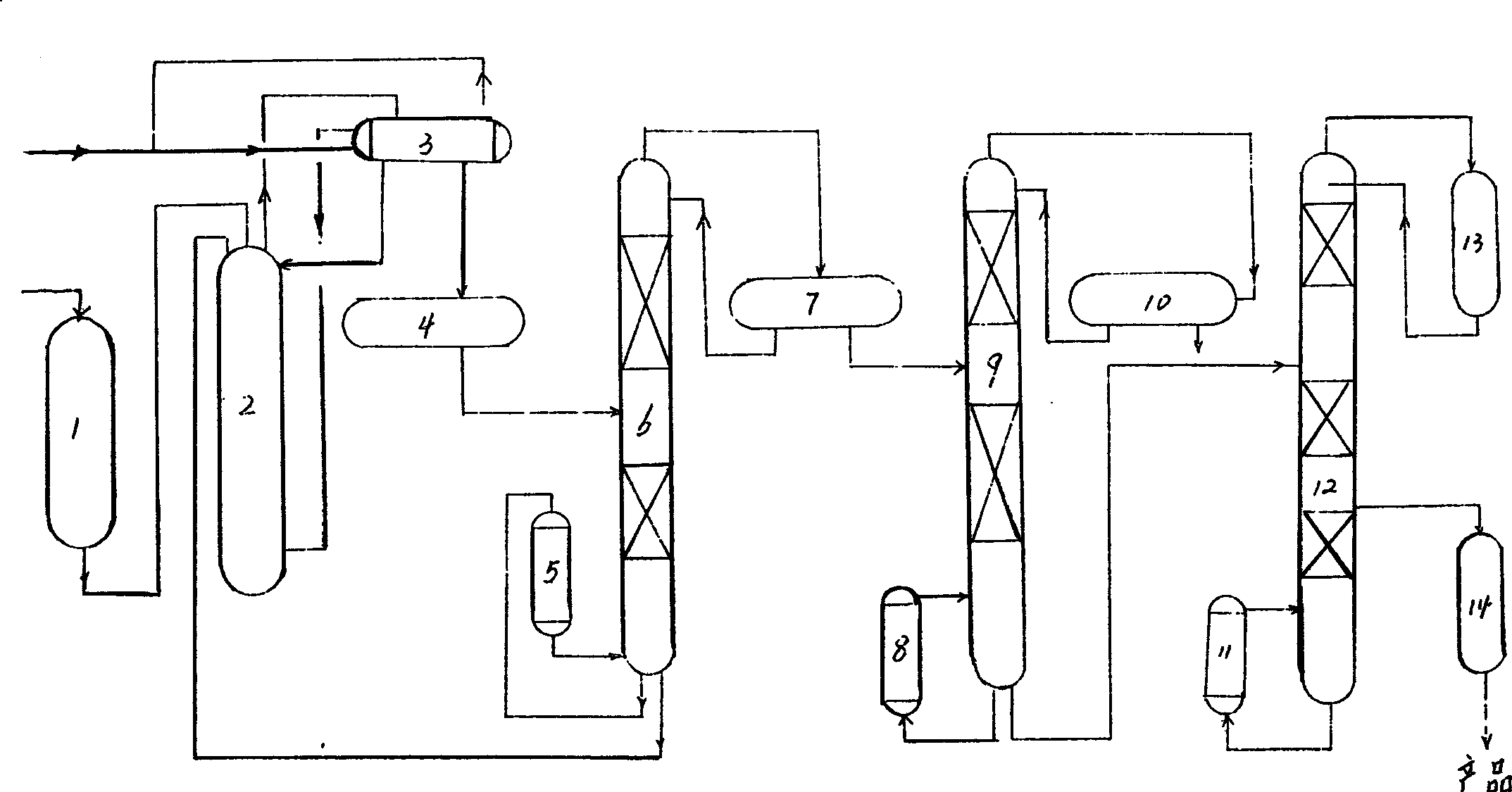

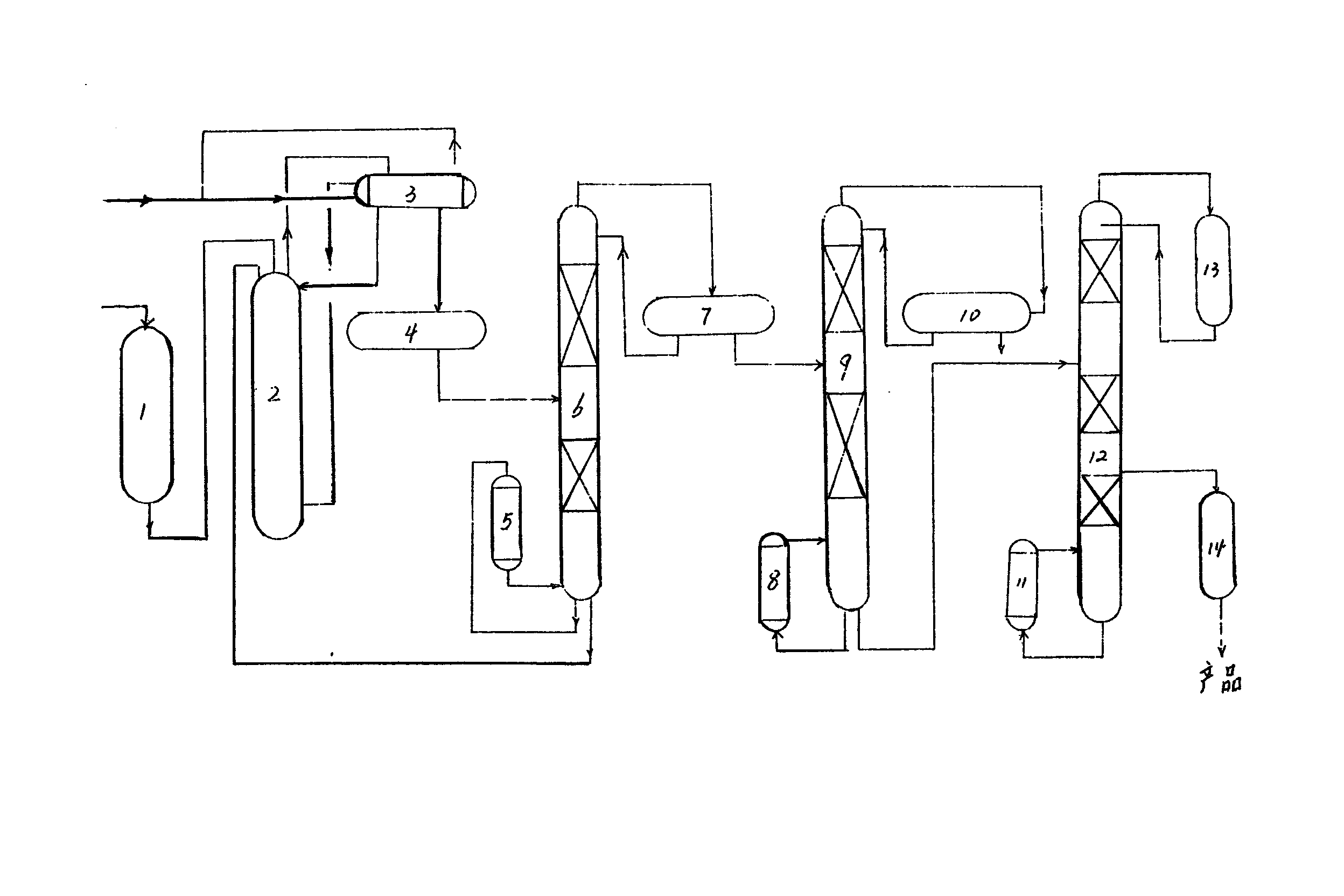

[0008] Below, the present invention will be further described in conjunction with the process flow chart of the present invention.

[0009] Cyclohexylimine is produced from caprolactam by catalytic hydrogenation reaction in a three-phase bed, and its reaction equation is The companion is water. First, the solid caprolactam is heated to 50°C-100°C in the melting tank 1 until it melts, and then pumped into the reactor 2 through a metering pump. After the hydrogen is heated, it is introduced into the reactor 2 from the gas distributor at the bottom of the reactor. Under the temperature of ℃-260℃ and the pressure of 10kg / cm2, under the conditions of catalyst and white oil, the reduction reaction between hydrogen and caprolactam occurs, and the generated cycloheximide enters the heat exchange together with the unreacted hydrogen in the form of gas Heat exchange with the circulating gas at 30-60°C in device 3. During this process, part of the caprolactam and solvent entrained in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com