Sensor system for pressure difference type detecting filter blocking state

A filter clogging, sensing system technology, applied in instruments, osmotic/dialysis water/sewage treatment, analytical materials, etc., can solve problems such as inability to accurately detect filter usage, high user requirements, and users at a loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

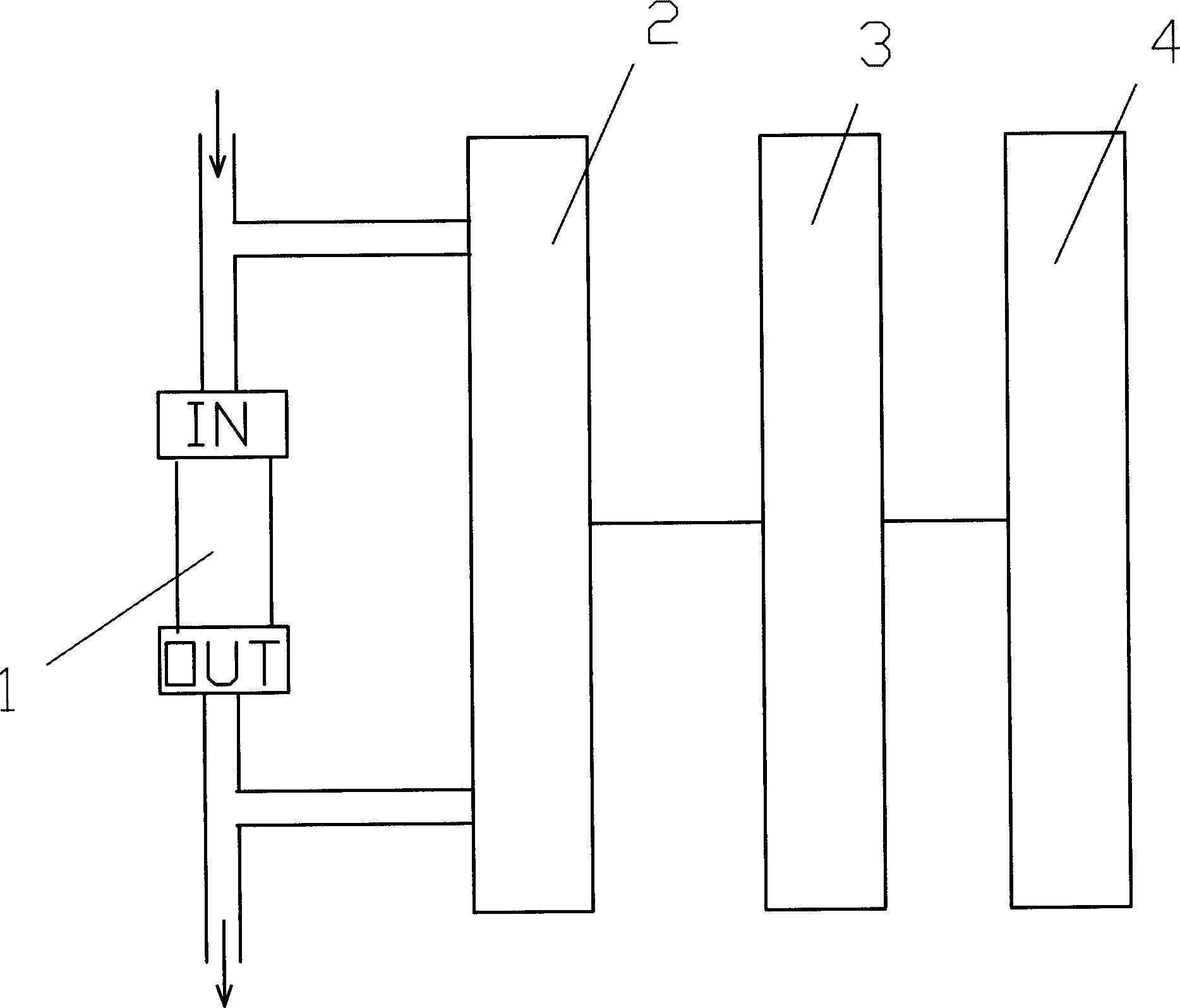

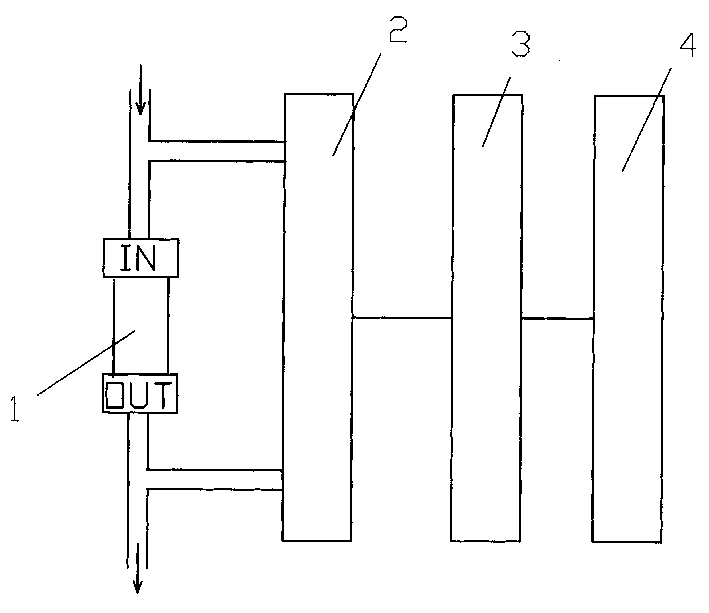

[0013] refer to figure 1 , a differential pressure sensing system for detecting filter clogging, comprising a filter 1, a differential pressure sensor 2 is installed on the filter 1, the differential pressure sensor 2 is connected with a filter clogging judging logic unit 3, when water is filtered from The input end of filter 1 enters and flows out from the output end. When the pressure at the input end is P1 and the pressure at the output end is P2, since the filter 1 has a blocking effect, P1>P2, when working, the pressure difference PV=P1- P2, gradually increases with the accumulation of filter impurities, resulting in a gradual weakening of the flow capacity. When the differential pressure sensor 2 detects that the PV value reaches the set value in the filter clogging judgment logic unit 3, it indicates that the filter 1 is over flow. If the flow capacity can no longer meet the requirements of normal work, the control system or control unit 4 will prompt the user to replac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com