Roller bed for a conveyor belt system

A transmission system and conveyor belt technology, applied in the field of bed track components and bed track components supporting conveyor belts, can solve problems such as material overflow, air pollution, and conveyor belt damage, and achieve the effects of increasing speed, reducing friction, and small diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

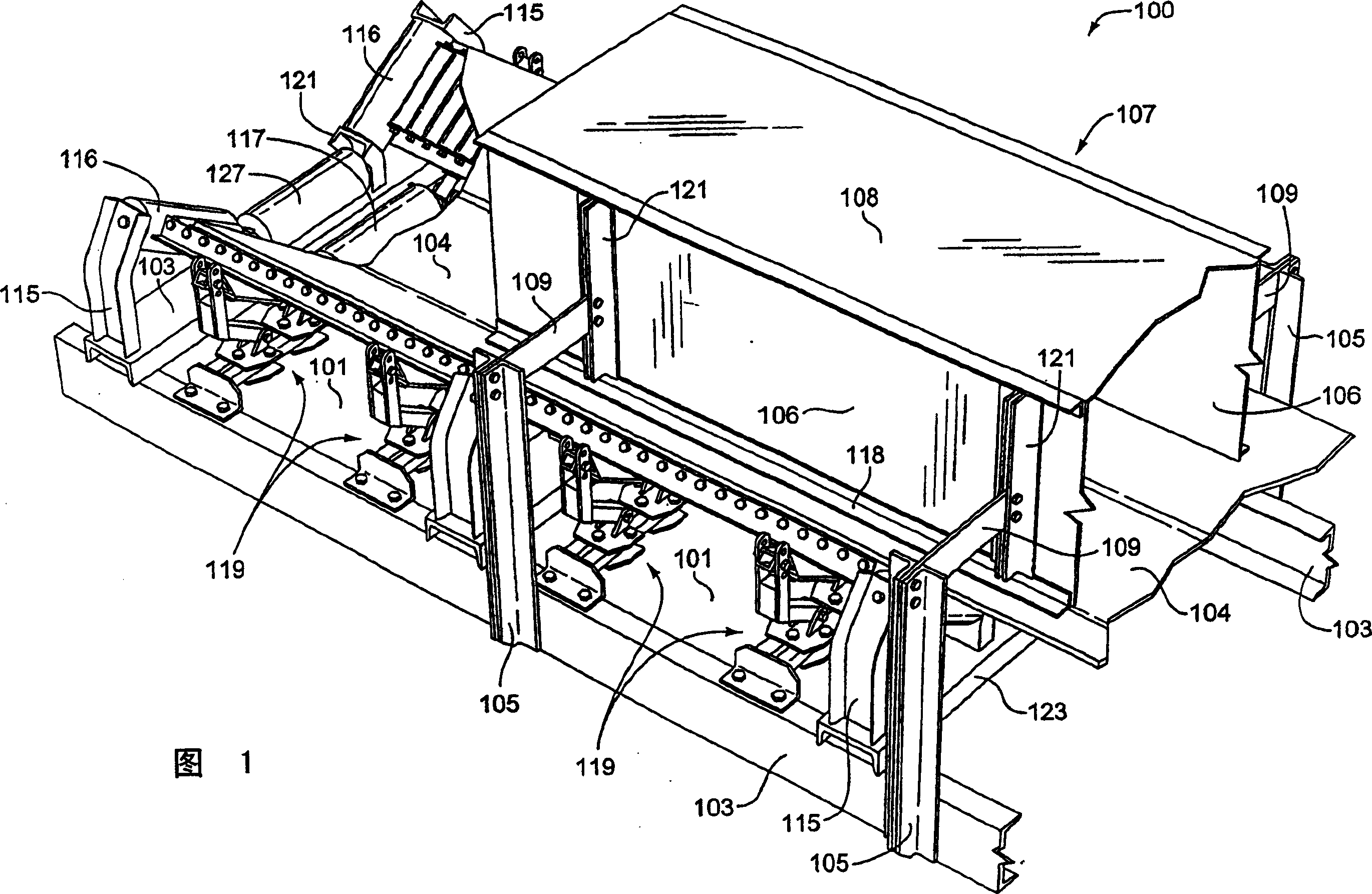

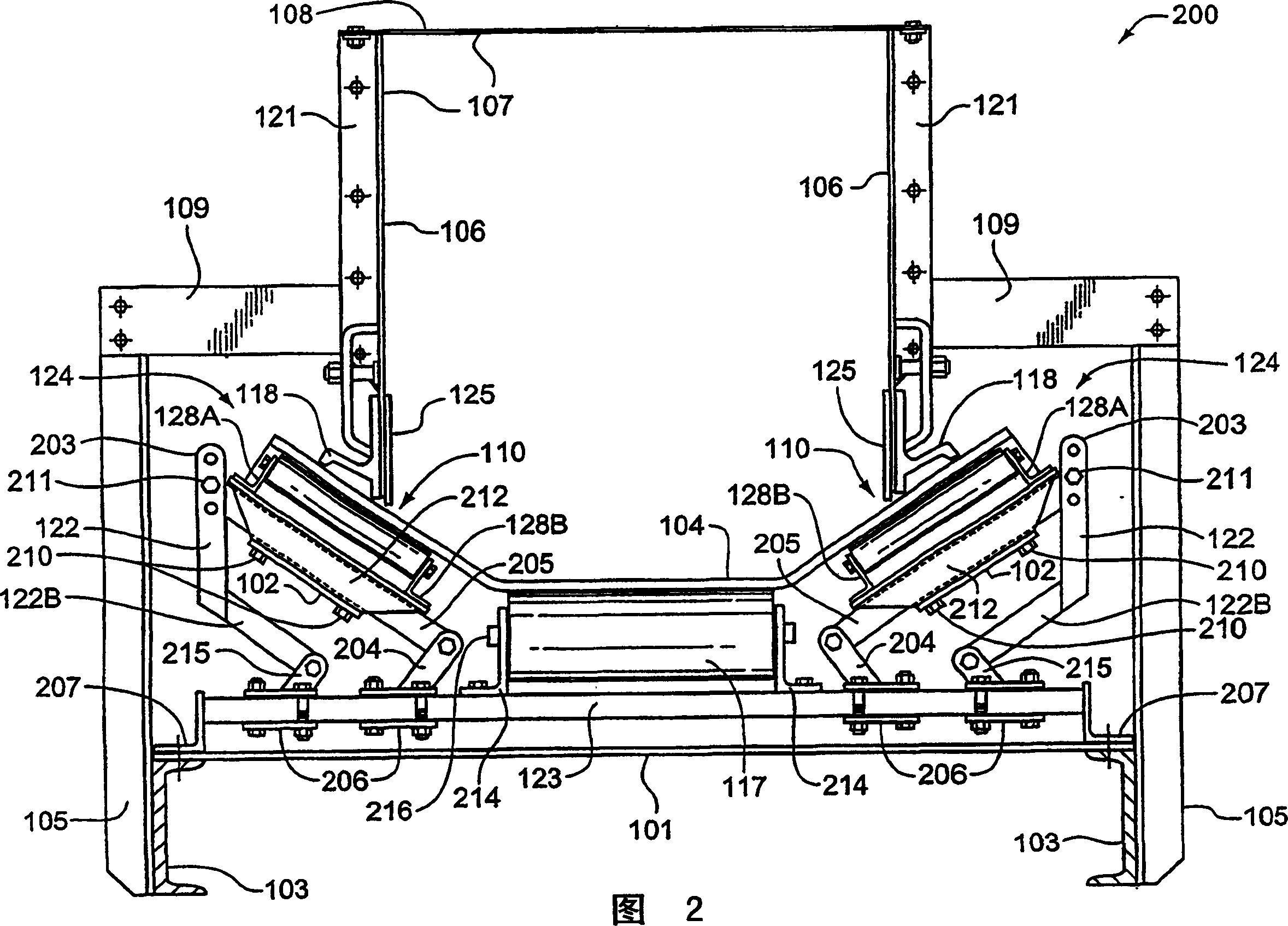

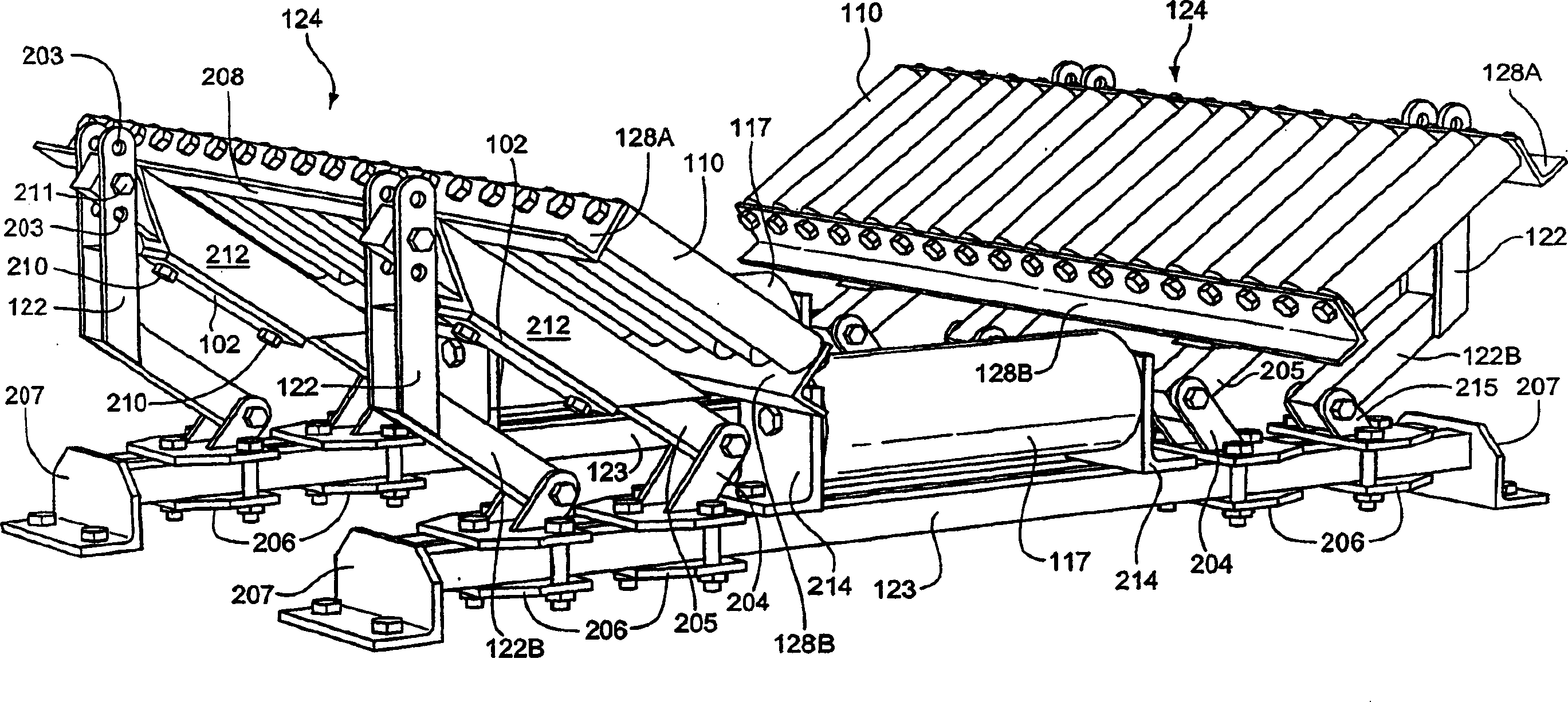

[0075] FIG. 1 discloses the roller bed track assembly of the present invention implemented in an existing conveyor system 100 having a top cover 107 , a cover 108 and vertical skirt walls 106 . Vertical supports 121 are attached to the vertical skirt side walls 106 . The vertical supports 121 are also connected to the horizontal skirt supports 109, each horizontal skirt support 109 is connected at its outer end to the vertical supports 105, and the vertical supports 105 are connected at their lower ends to the stringers 103 , the stringer 103 comprises a lower base for the conveyor system 100 .

[0076] The equipment provided according to the invention comprises four conveyor slide bed installations 119 shown in FIG. 1 . The slide bed apparatus 119 includes a plurality of inclined rollers 110 which are shown inclined at an inclined angle in order to support the inclined sides of the belt 104 . This slope includes material being carried by the conveyor belt 104 while preventi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap