Turbulent_washing gas treating apparatus

A gas treatment and washing tower technology, which is used in the purification of smelting acid-making flue gas and the dust removal and desulfurization of coal-fired flue gas, chemical industry, and environmental protection equipment manufacturing. The effect of high desulfurization efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

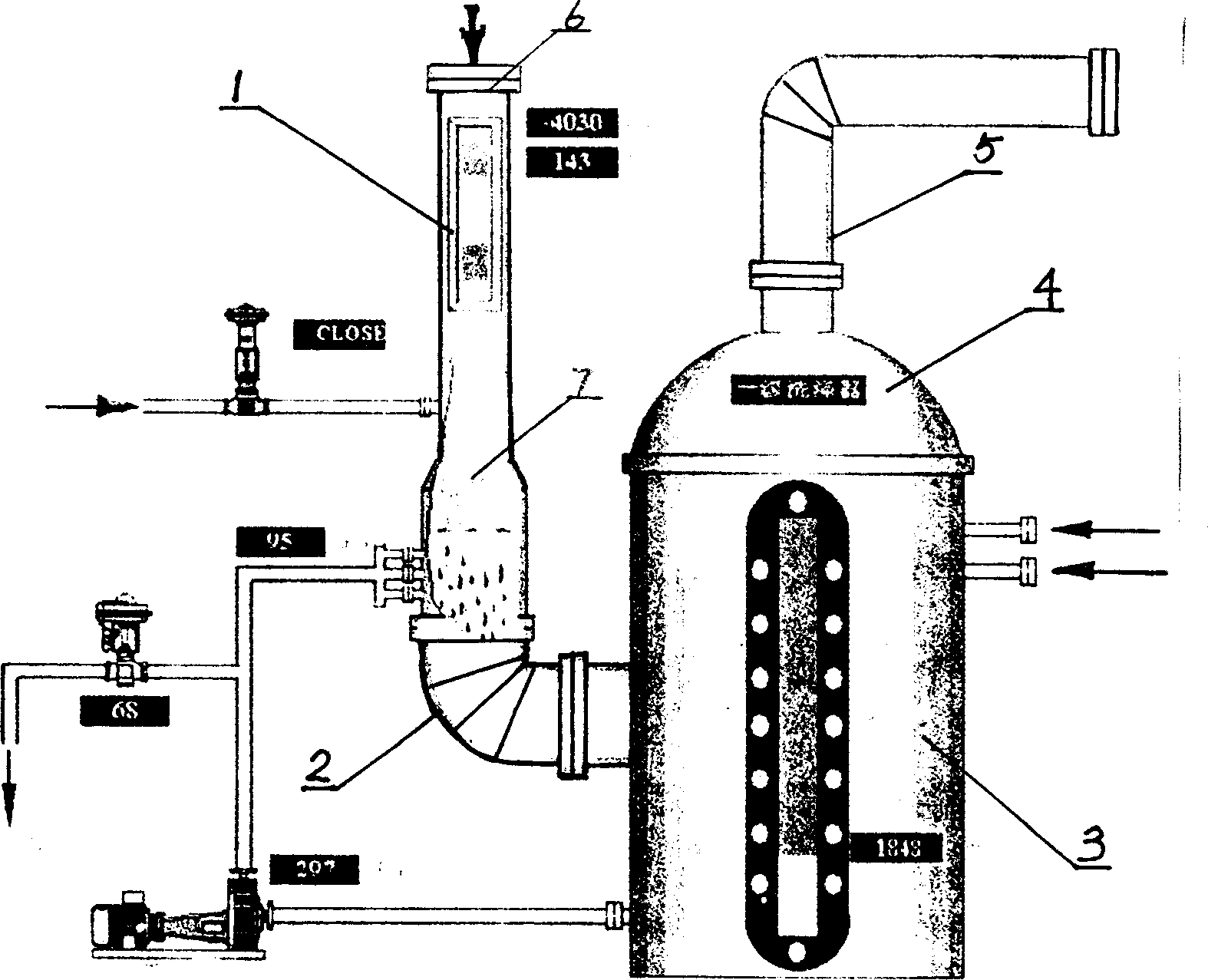

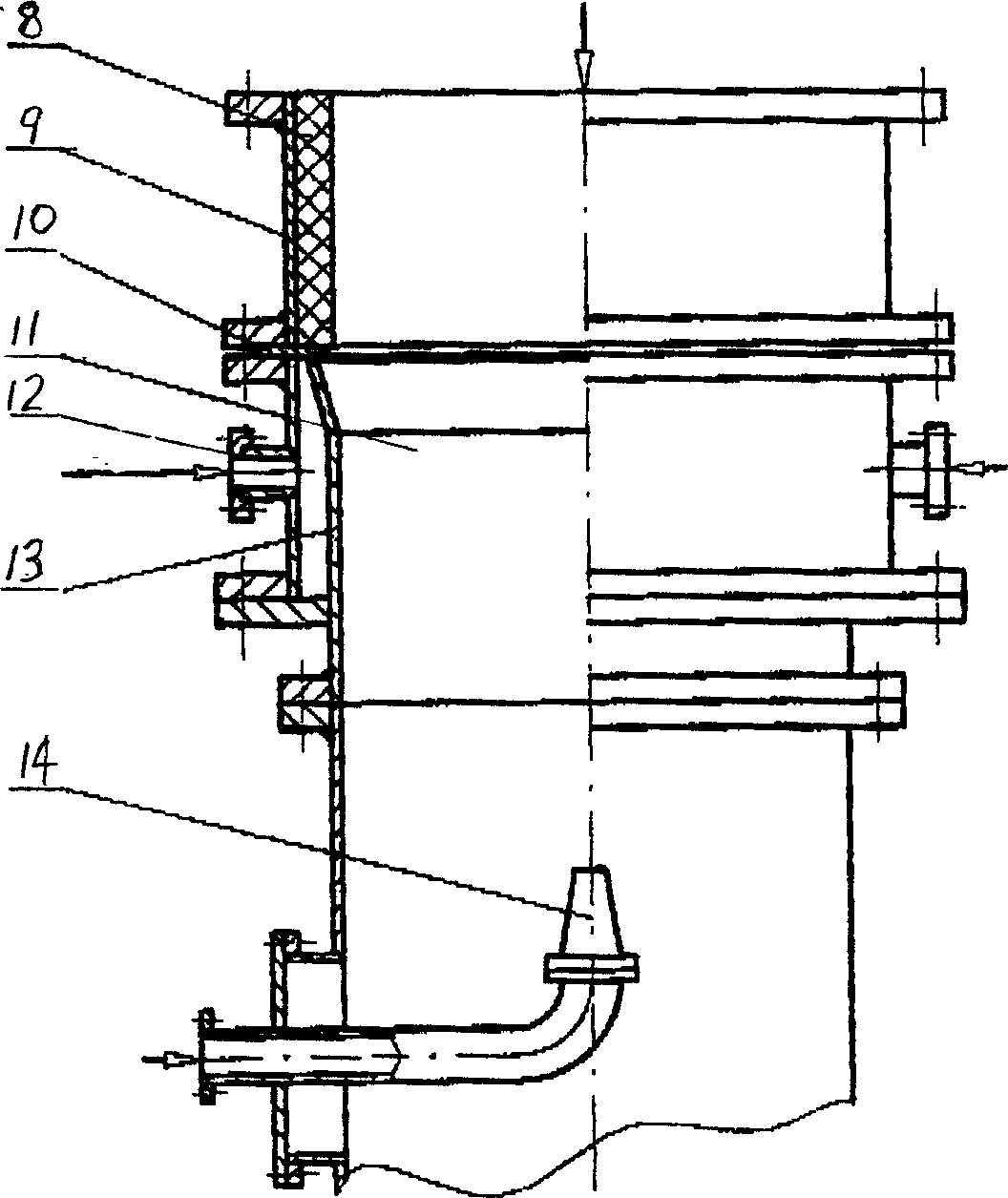

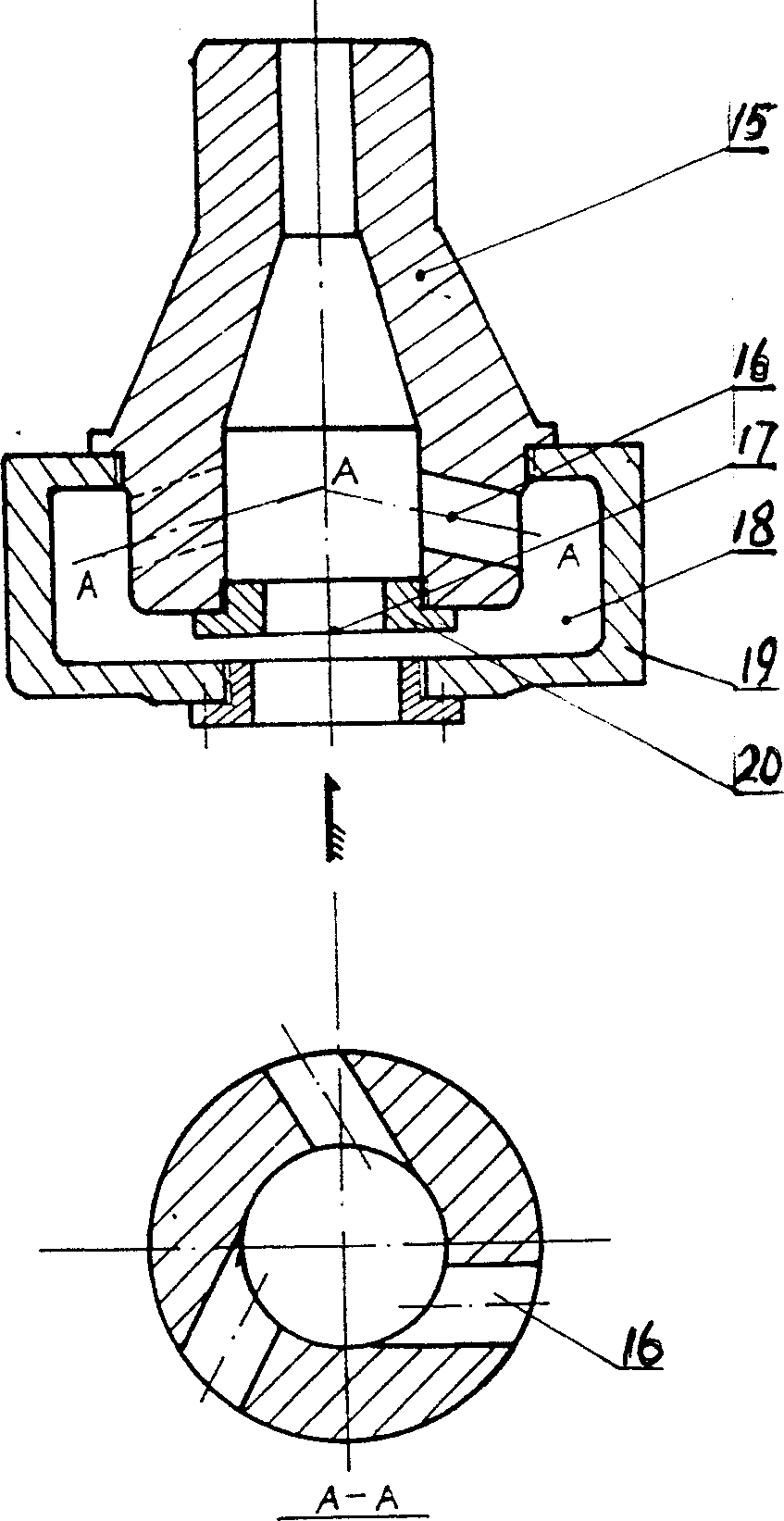

[0017] The turbulent scrubbing gas treatment device is a cylindrical tower structure, which mainly includes a washing tower 1, a sump 3, a demister 4, and a washing nozzle 14. The demister 4 is arranged above the sump 3. The washing tower 1 is a cylindrical tower structure, and the washing tower 1 is connected with the sump 3 and the demister 4 through the bellows 2, and forms a whole. On the top of the washing tower 1, an overflow weir 6 and a transition section 8 are arranged, and below the overflow weir 6, a dynamic equilibrium exchange field 7 for flue gas and washing liquid is arranged. The transition section 8 is the input part of high-temperature flue gas. A gasket 10 is provided between the overflow weir 6 and the transition section 8 ; and an inner sleeve 9 is provided in the transition section 8 . The overflow weir 6 has an inner and outer chamber structure, and its outer chamber 13 is connected to the water inlet pipe 12; the washing nozzle 14 is arranged in the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com