Movable vehicle container checking systems

A technology for inspection systems and containers, which is applied in the field of radiation imaging, can solve problems such as limiting the use range of devices, not being able to inspect vehicle chassis, and increasing the difficulty of layout, and achieve good radiation protection performance, small footprint, and simple layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

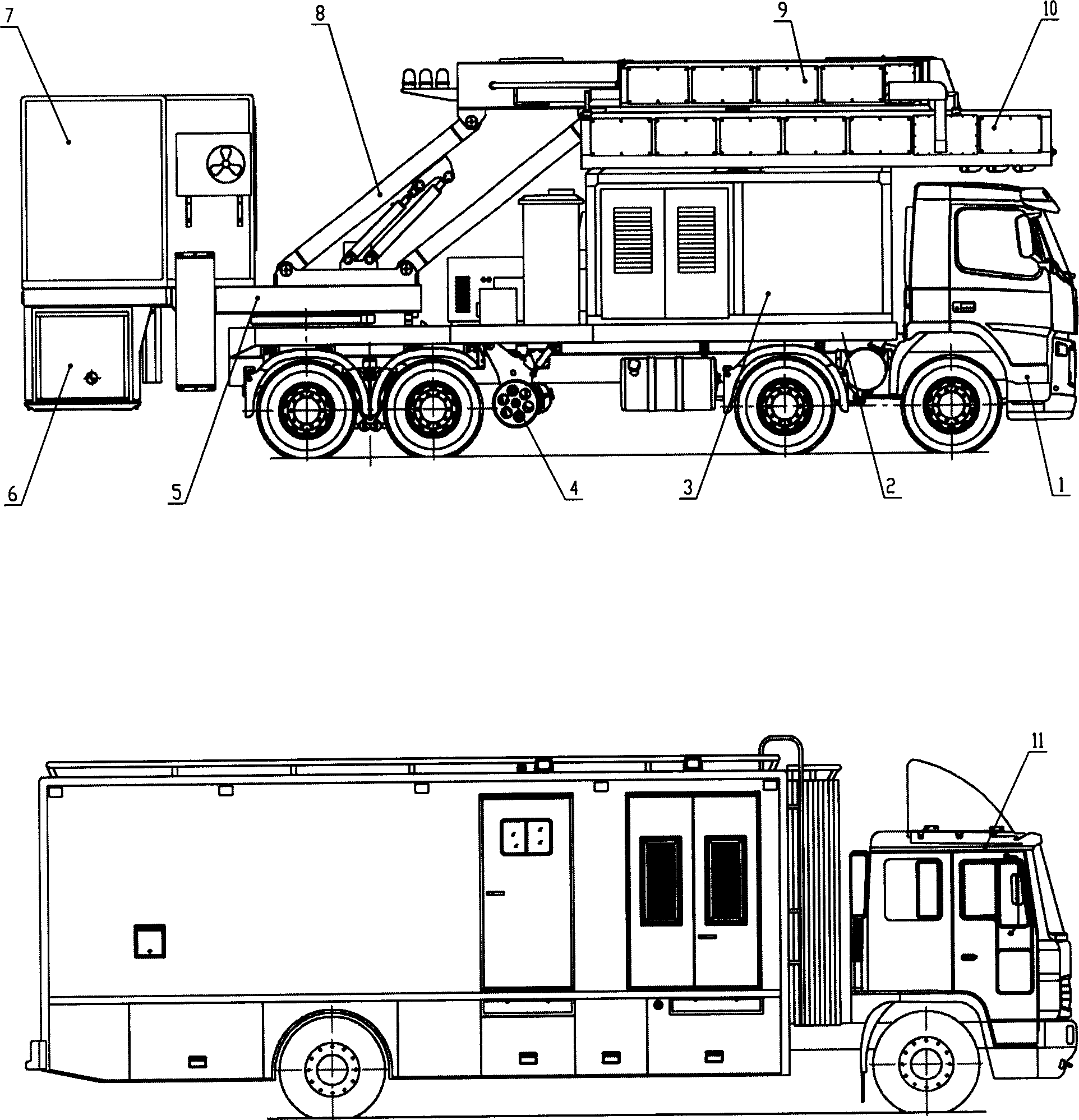

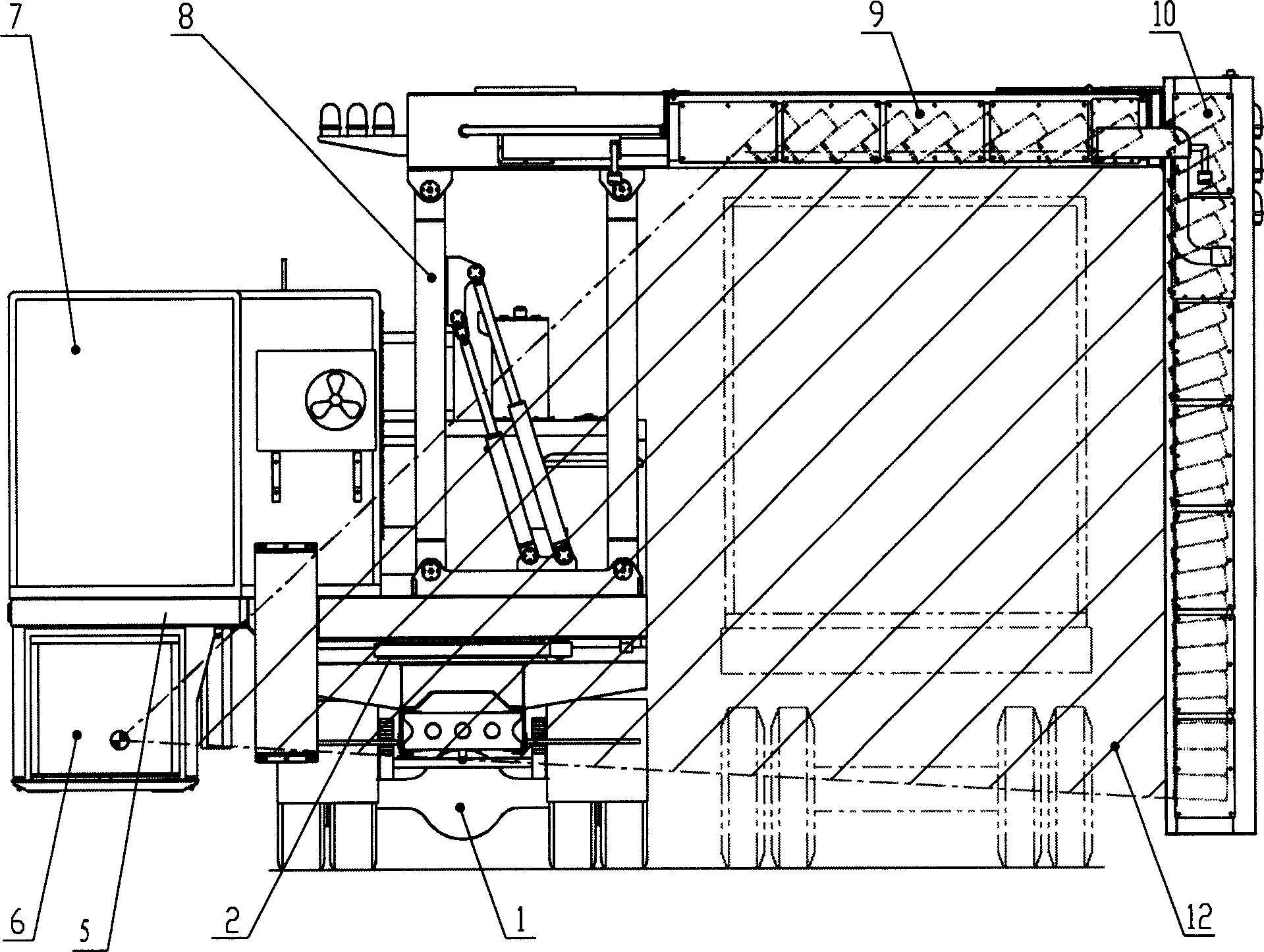

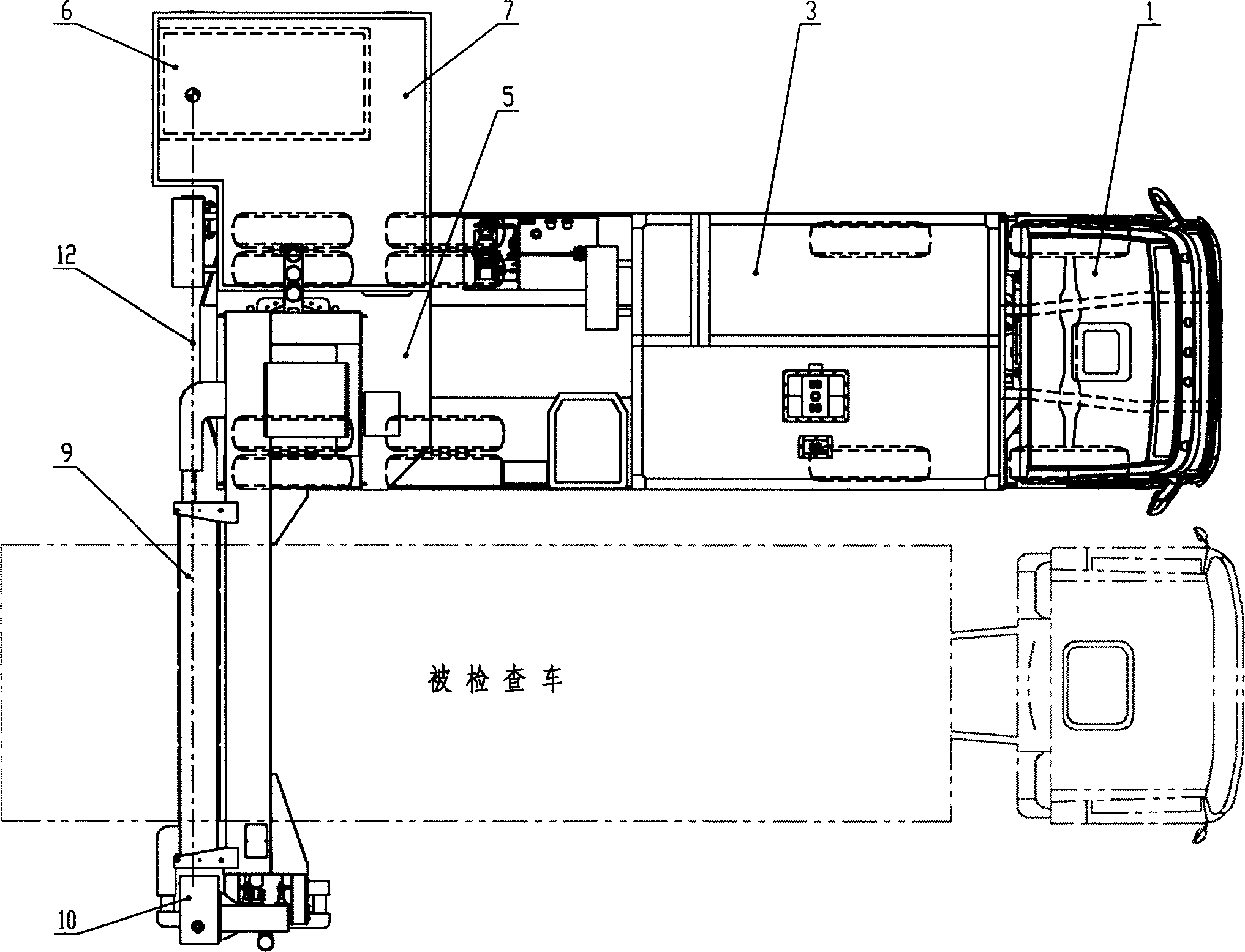

[0019] see Figure 1 ~ Figure 3 , a vehicle-mounted mobile container inspection system includes two vehicles, one vehicle is a scanning vehicle 1, the other vehicle is a control vehicle 11 and the remote control devices of the two vehicles. The body bracket of the scanning vehicle 1 adopts a universal chassis 2, and the front part of the universal chassis 2 is a first box-shaped cabin 3. The first box-shaped cabin 3 is equipped with a radio communication machine, a motor and its control device, and a working room with a scanning control module and a running inspection module made of X-ray protective materials. The rear portion of universal chassis 2 is equipped with a rotary platform 5 that can move relatively. A parallelogram support 8 composed of a four-bar linkage mechanism is installed on the slewing platform 5 . The horizontal connecting rod on the parallelogram bracket 8 extends to be a horizontal cantilever 9 equipped with a detector. The other end of the horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com