Plasma cutting electrode vacuum soldering method

A technology of cutting electrodes and brazing method, applied in the field of vacuum brazing of ion cutting electrodes, can solve problems such as ineffective welding, and achieve the effects of good surface quality, stable quality, uniform and dense welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

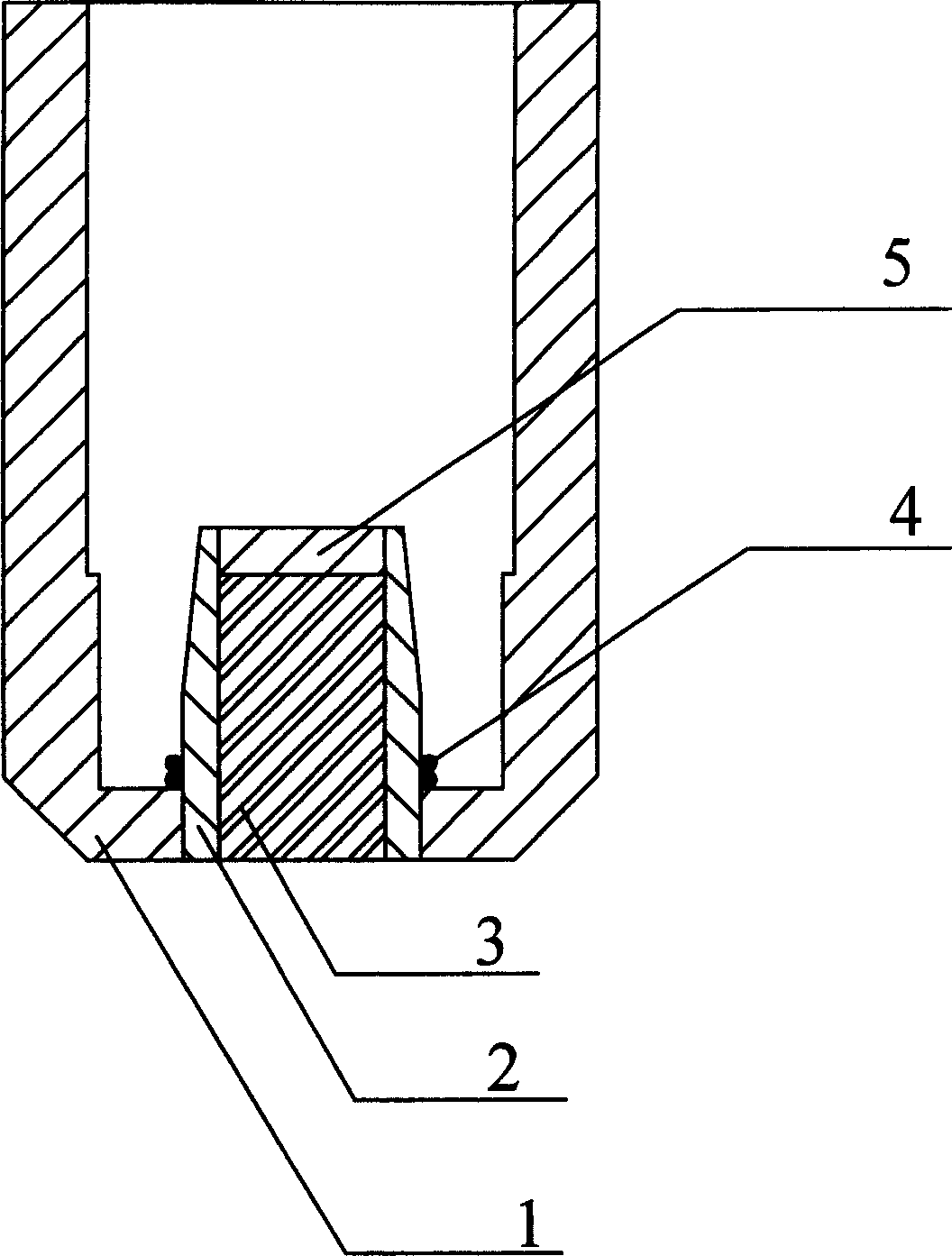

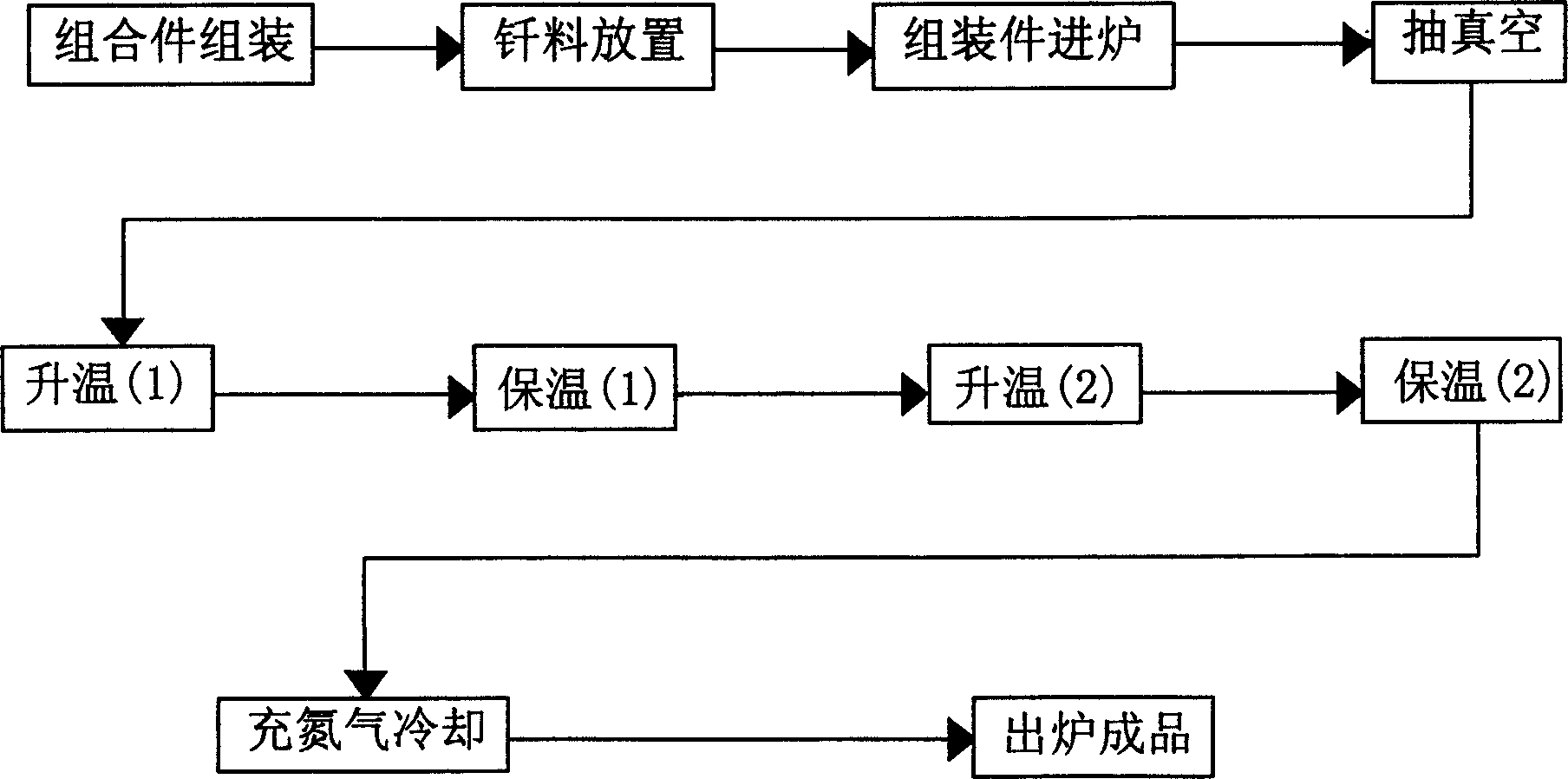

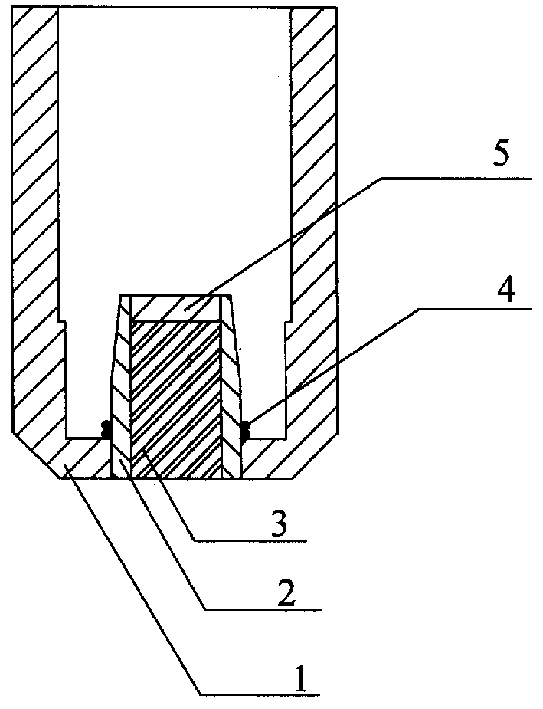

[0025] According to attached figure 1 First, assemble the oxygen-free copper sleeve and the silver body, the silver body and the hafnium wire core at a gap of 0.04mm, and place silver-copper brazing wire and silver-copper brazing sheet in the gap. Then, the assembly is placed on a rack and pushed into a vacuum furnace for vacuum brazing. Described vacuum furnace is commercially available routine product. Vacuum the vacuum furnace to 5 x 10 -2 pa, and raise the temperature of the vacuum furnace to 600°C (heating (1) in the block diagram), keep it warm for 1 hour (heating (1) in the block diagram), and then raise the temperature to 840°C (heating (2) in the block diagram), and keep it warm for 10 minutes ( Insulation (2)) in the block diagram, filled with nitrogen, cooled and released to obtain qualified products.

Embodiment 2

[0027] Select a gap of 0.03mm between the oxygen-free copper sleeve and the silver body, and the silver body and the hafnium wire core, and vacuum the vacuum furnace to 3×10 -2 pa, first raise the temperature to 600°C, keep it warm for 1 hour, then raise the temperature to 830°C, keep it warm for 10 minutes, fill it with nitrogen, and take it out of the furnace after cooling to obtain a qualified product. Others are as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com