Optical module and its manufacturing method

A technology of an optical module and a manufacturing method, which is applied in the field of optical modules and can solve the problems of difficult and economical taper part processing and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

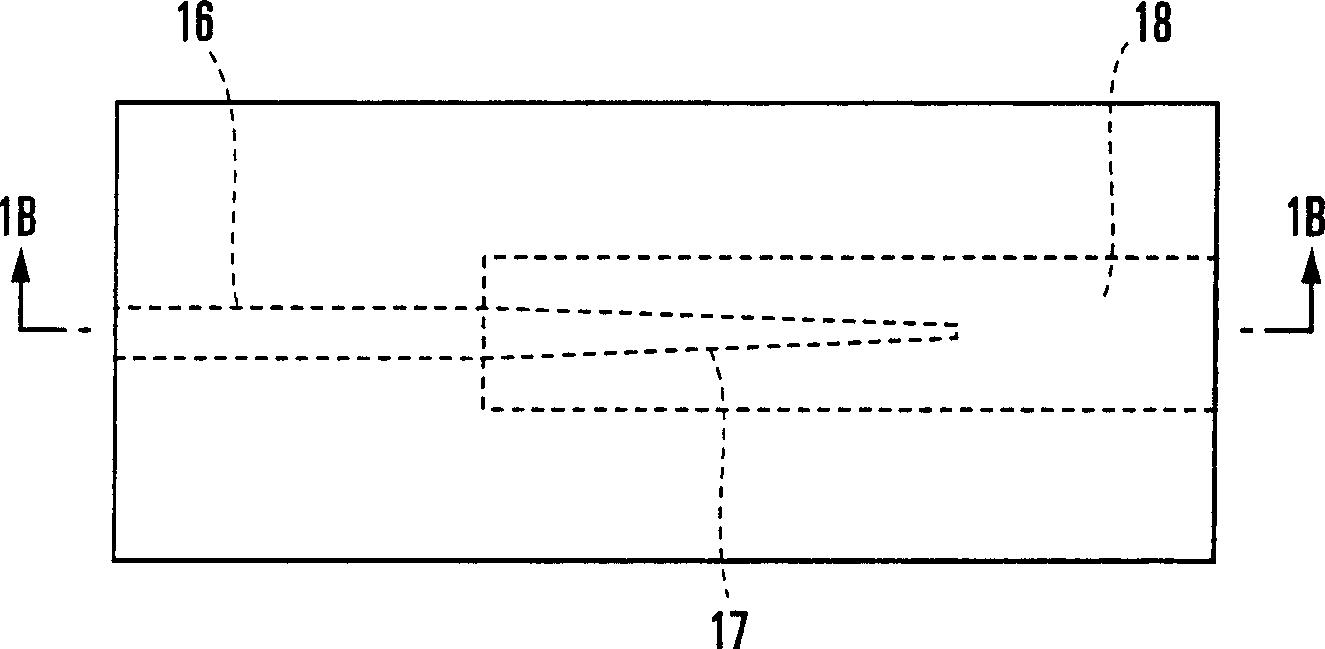

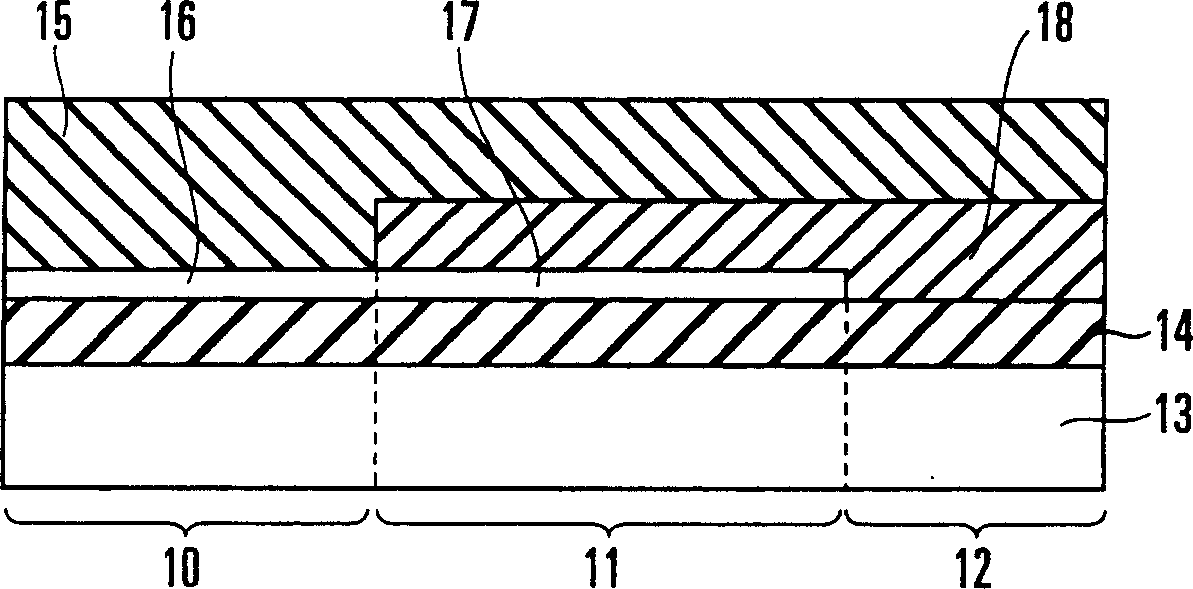

[0055] Figures 3A to 3C An optical module according to a first embodiment of the present invention is shown. refer to Figures 3A to 3C , reference numeral 20 denotes a first optical waveguide made of silicon like an electric wire; 21 denotes a mode field size conversion portion; 22 denotes a second optical waveguide connected to the first optical waveguide 20; 23 denotes a silicon substrate; 24 denotes a A lower cladding layer formed of a silicon dioxide film and provided over a silicon substrate 23; 25 denotes an upper cladding layer made of a polymer; 26 denotes a cladding layer made of silicon and forming the first optical waveguide 20 27 represents a tapered portion made of the same silicon as the first core 26, wherein, in accordance with its width dimension, decreases toward its end, while the height (thickness) of the cross-section of the core 26 remains 28 represents the second core that is made of polymer and is the core of the mode field size conversion portion 2...

no. 2 example

[0075] Figures 7A to 7C An optical module according to a second embodiment of the present invention is shown. exist Figures 7A to 7C in, with Figures 3A to 3C Like reference numerals denote like parts. The present embodiment is characterized in that silicon dioxide film 30 is formed only adjacent to the side surface of tapered portion 27 . This enables the tapered portion 27 to be shaped with high precision.

[0076] The following will refer to Figures 8A to 8G to describe Figures 7A to 7C The fabrication method of the optical module is shown.

[0077] exist Figures 8A to 8D The steps in are the same as those in the first embodiment Figures 4A to 4D The steps are the same as in . In the first embodiment, by using the mask 29 to etch the silicon layer 31, the first core 26 of the first optical waveguide 20 and the tapered portion 27 continuous with the core 26 are formed, and the mask 29 is removed. After that, an oxidation process is performed. In this embodi...

no. 3 example

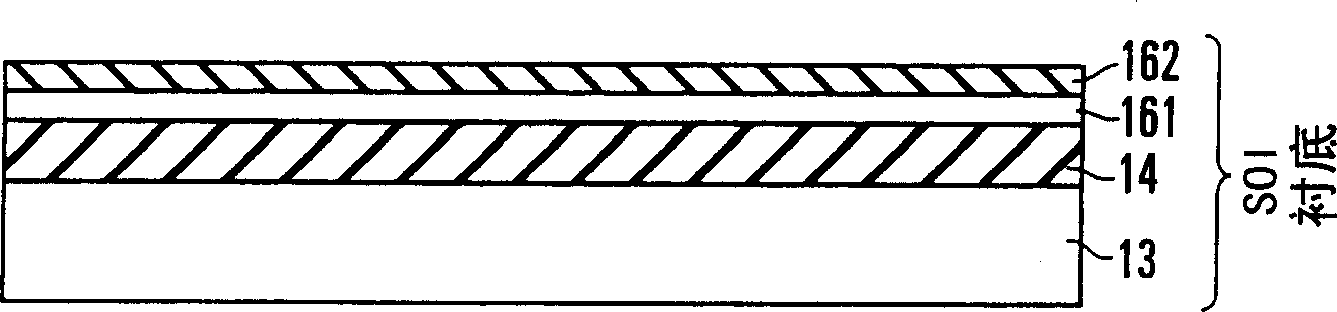

[0086] This example is for Figures 4A to 4H The improvement of the manufacturing method of the optical module is shown, and only a part of the method is exemplified, wherein, in particular, after the silicon layer serving as the first core is formed on the lower cladding layer, a silicon dioxide film is formed to cover the first fiber core. Using this embodiment, optical modules can be manufactured in a shorter manufacturing time period than conventional methods.

[0087] refer to Figures 9A to 9C , reference numeral 111 represents a silicon substrate; 112 represents a silicon dioxide film (SiO 2 ) formed under cladding; and, 113 denotes the core serving both as the first core and the tapered portion of the first optical waveguide in the above-described first embodiment. The core 113 is made of silicon, and forms a pattern of thin electric wires. Reference numeral 114 denotes a silica film provided to cover the core 113 . In this case, the width and thickness of the core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com