Automatic control equipment of double screw extrusion machine

A twin-screw extruder and automatic control device technology, which is applied in the field of twin-screw extruder automatic control devices, can solve problems affecting normal continuous operation, poor temperature control accuracy, and need to stop for repairs, so as to save cooling auxiliary equipment , Improve the temperature control accuracy, the effect of good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

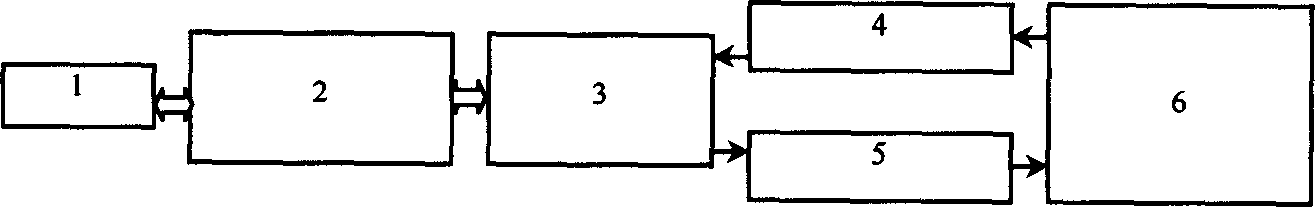

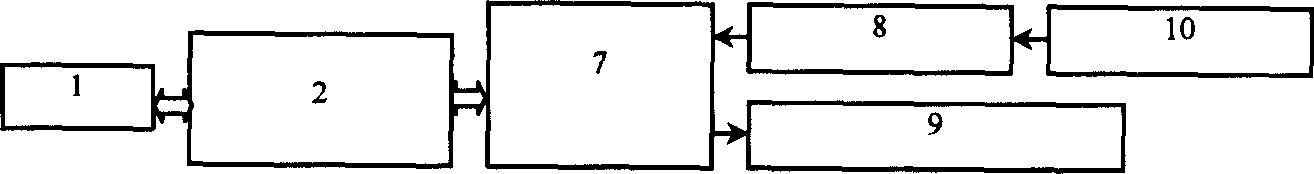

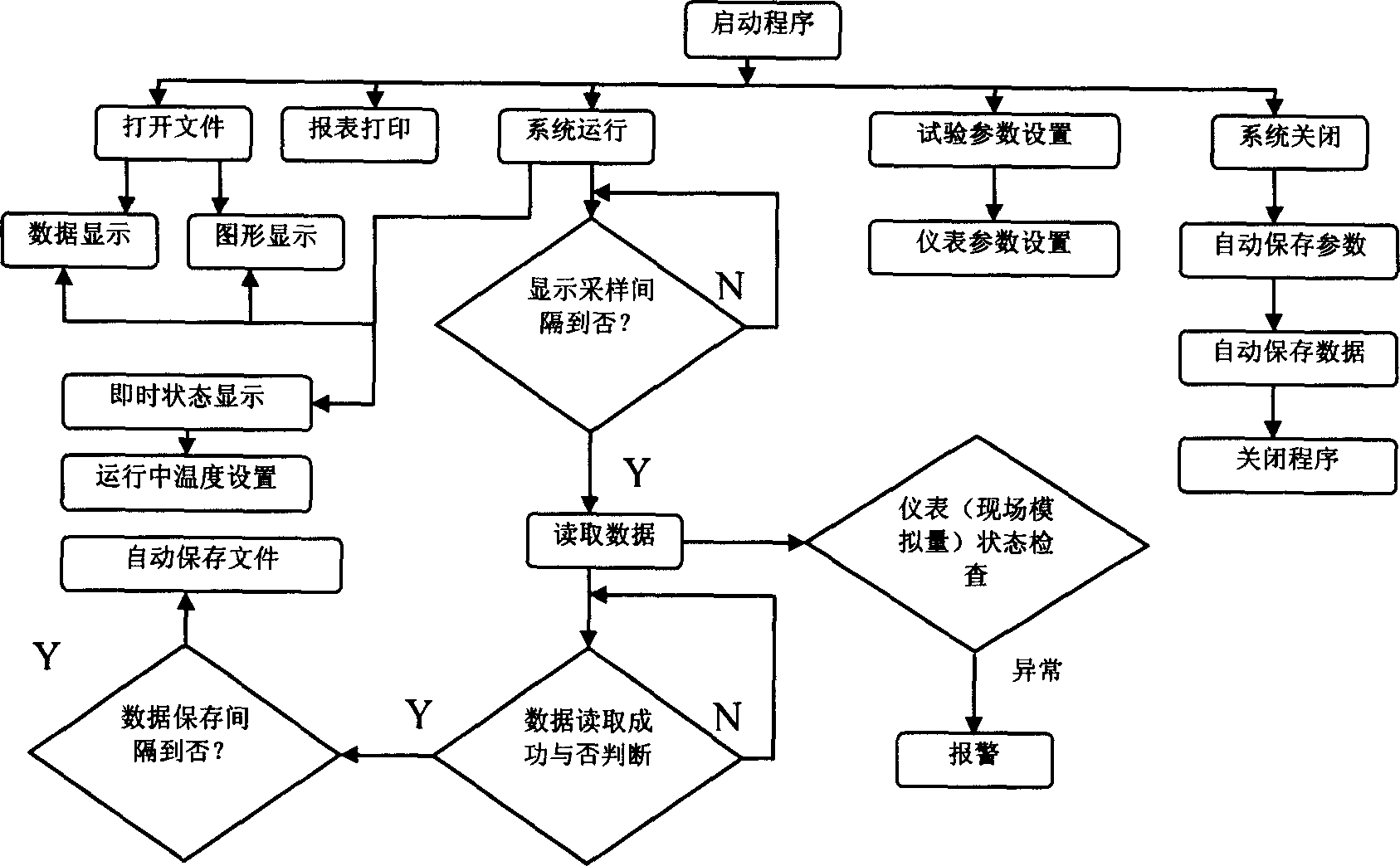

[0033] Attached figure 1 , attached figure 2 and attached image 3 The twin-screw extruder system set up has been running smoothly for more than a month without any failures. Even if the microcomputer fails (or shuts down the microcomputer), the normal production of the device will not be affected except for data recording and some alarms; if a smart instrument is damaged or does not work properly, the system can detect and alarm in time, and can be replaced in time (On-site simulation test has been done). During normal and stable operation, the temperature is set and controlled at about 200°C, and the temperature fluctuation is ±1°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com