Blank drawing technology for crystallizer of conticaster and special crystallizer structure

A mold and continuous casting machine technology, which is applied in the field of structural improvement of special molds, can solve problems such as casting slab stuck in the mold, slab shell cracking, and slab casting resistance increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following describes the embodiments of the present invention in further detail with reference to the accompanying drawings:

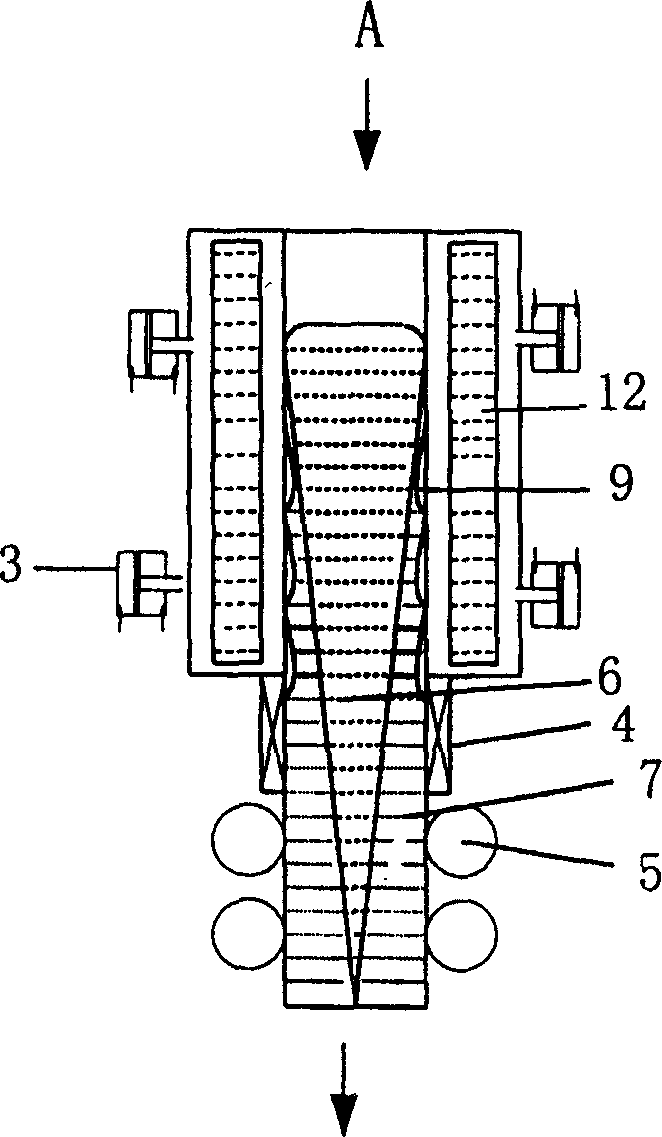

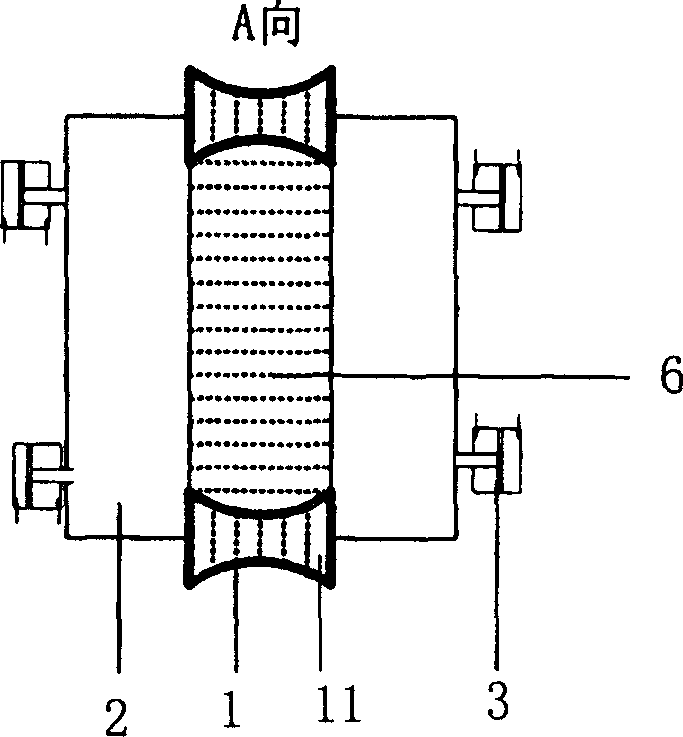

[0022] figure 1 Is an implementation mode of the present invention, figure 2 The structure of the crystallizer of the present invention is shown. The structure of the mold is composed of two narrow-sided copper plates 1 and two broad-sided copper plates 2, and four servo hydraulic cylinders 3 act on the outer wall of the broad-sided copper plate 2 to lock and press it into a combined slab mold. The structure of the two narrow-side copper plates 1 in this embodiment can be the structure of the narrow-side copper plate elastic body as shown in Figs. 9, 10, and 11, and there is a cavity 11 filled with cooling water in the body. The cavity 11 passes through the cooling water. The water inlet 13 and the water outlet 14 input cooling water with pulsating pressure into the cavity. There are also cavities 12 filled with cooling water in the two broad-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com