Method for mfg of net screen of electrode free illumination device

A technology for lighting devices and manufacturing methods, applied to circuits, discharge lamps, electrical components, etc., can solve the problems of metal plating deformation, discoloration or accelerated oxidation, shortened service life, etc., to achieve enhanced retention strength, improved light characteristics, improved The effect of the characteristic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

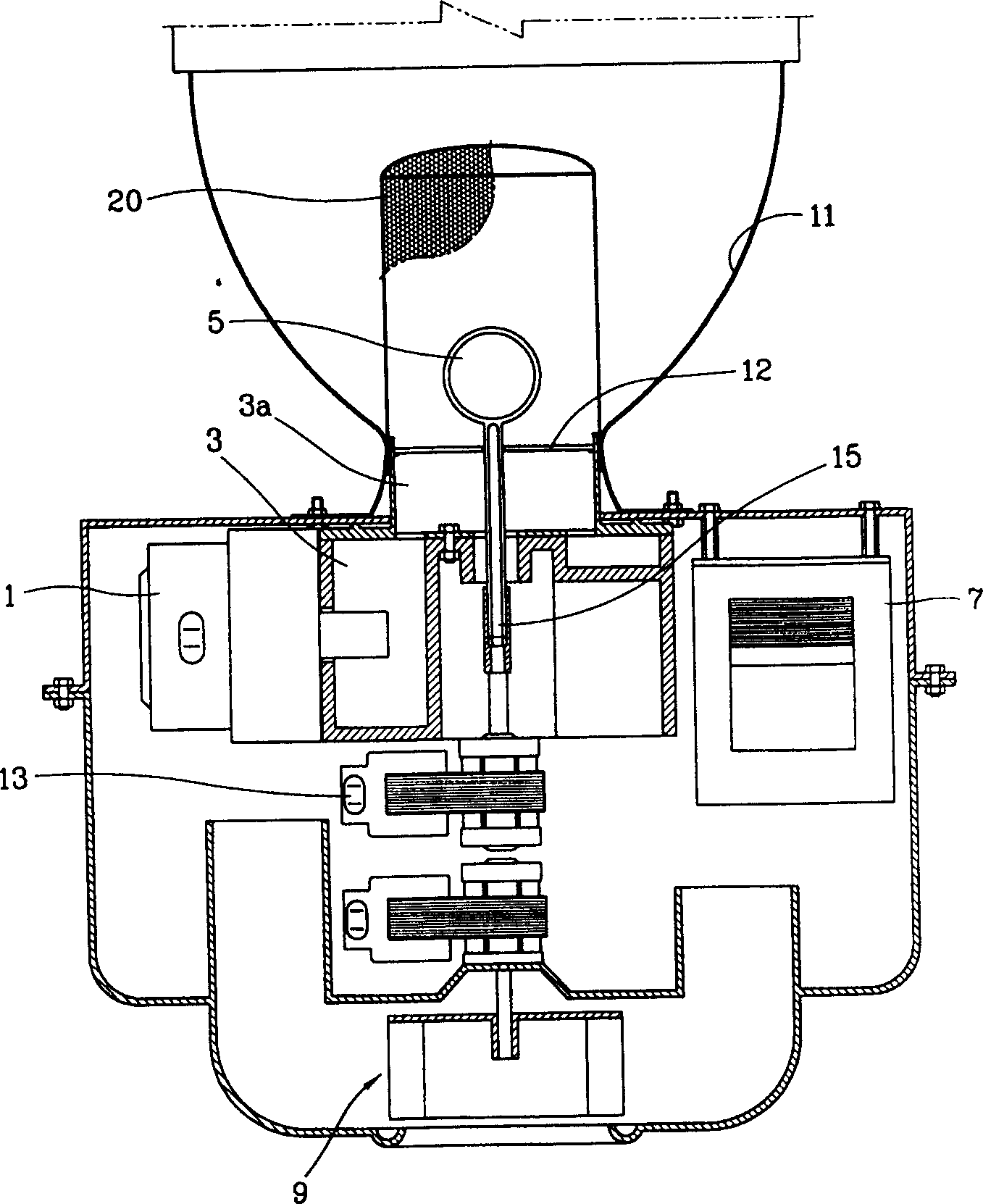

Embodiment Construction

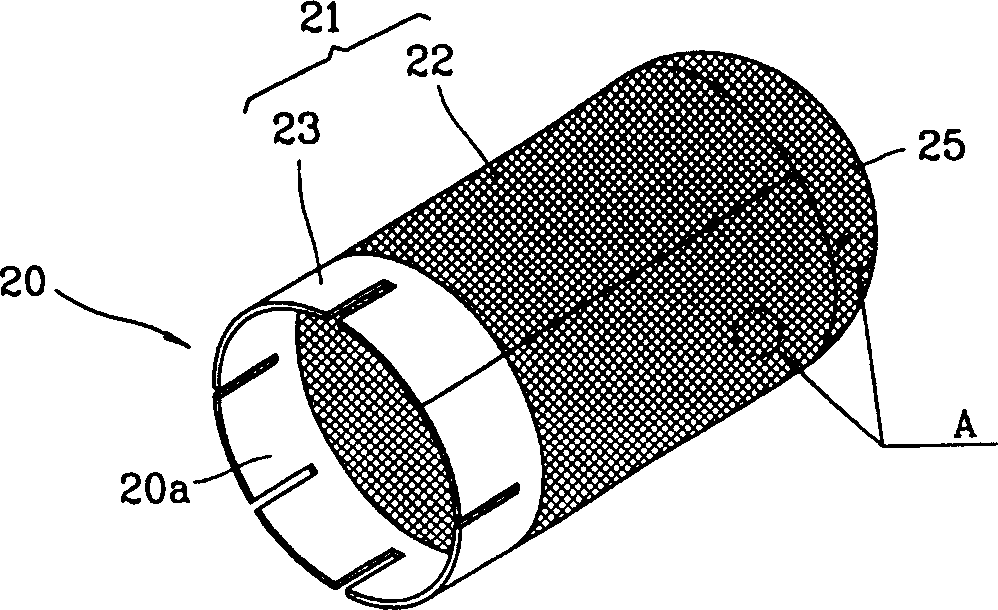

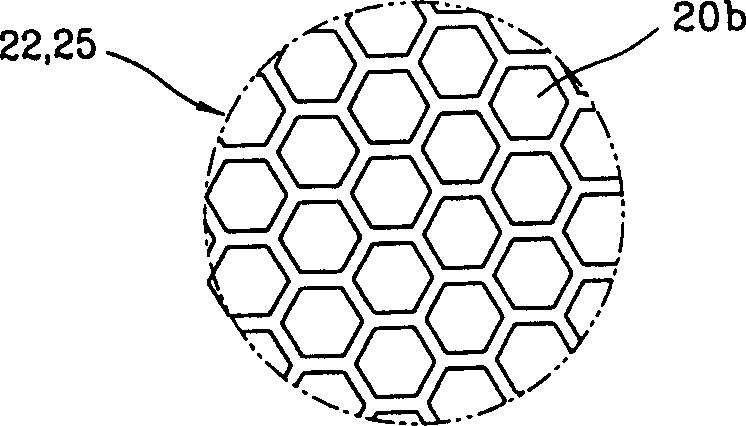

[0049] Such as Figure 5 As shown, the manufacturing method of the mesh screen of the electrodeless lighting device of the present invention is realized in the following order: the metal sheets of a certain thickness are respectively cut into quadrilaterals and circles so as to form the base material forming stage of the basic base material (S 1 ), in order to form a network structure on the above-mentioned basic base material, it is etched (etching) to form a mesh formation stage that constitutes a network structure (S 2 ), if the mesh structure has been formed, then after the cylindrical portion (21) is made, the cover portion (25) is assembled on the cylindrical portion (21), thereby forming a mesh forming stage (S 3 ), the first metal coating stage (S 4 ), the vacuum heat treatment stage (S 5 ), the second metal coating stage (S 6 ), coated with a photocatalyst substance (TiO 2 ) photocatalyst coating stage (S 7 ).

[0050] The procedures of the above-mentioned stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com