NOx-reduced burning method and apparatus

A combustion method and combustion device technology, applied in the combustion method, burner, combustion type, etc., can solve the problems of increased heat loss, corrosion of machine components, and increased dew condensation, and achieve the effect of high industrial utilization value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

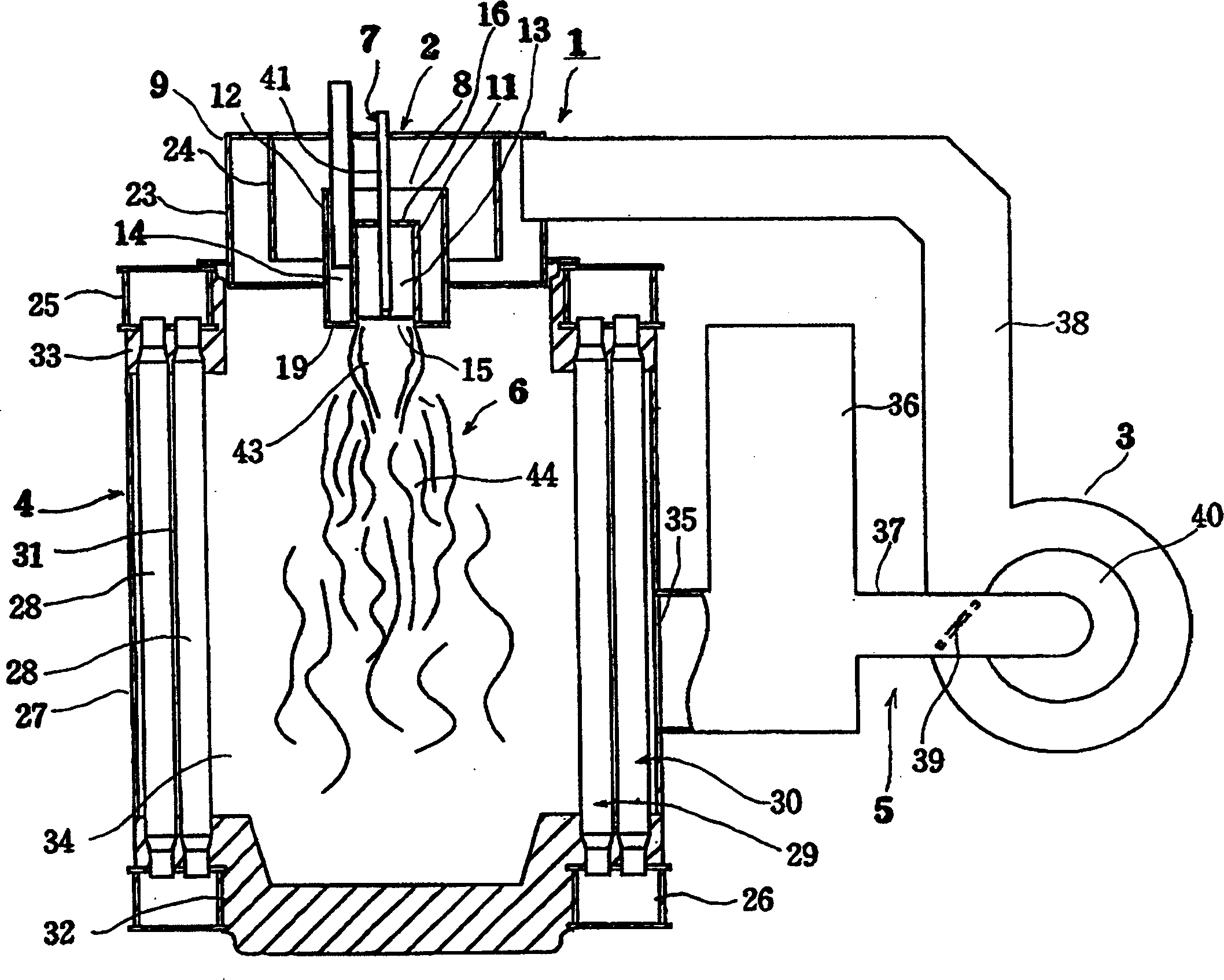

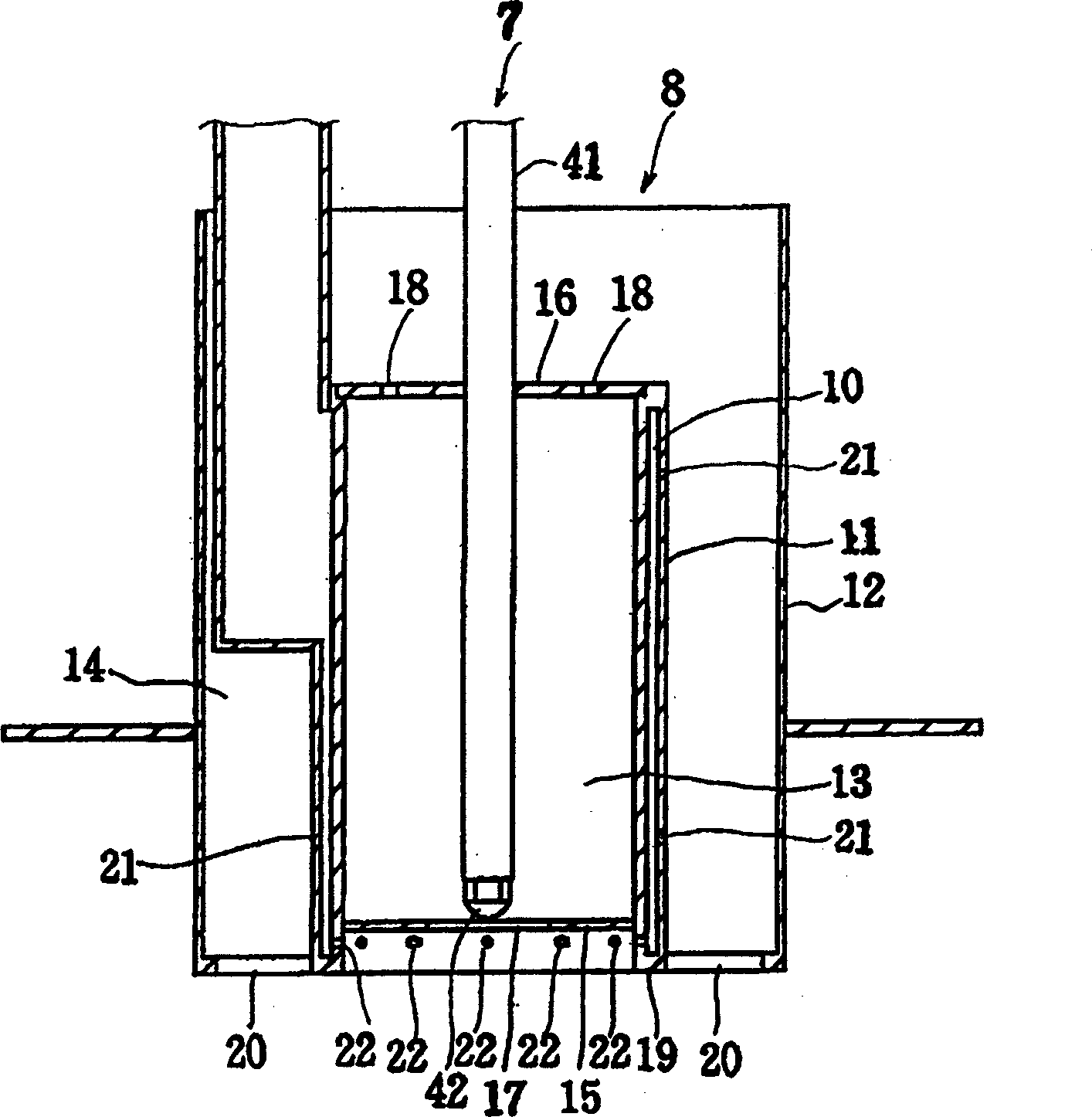

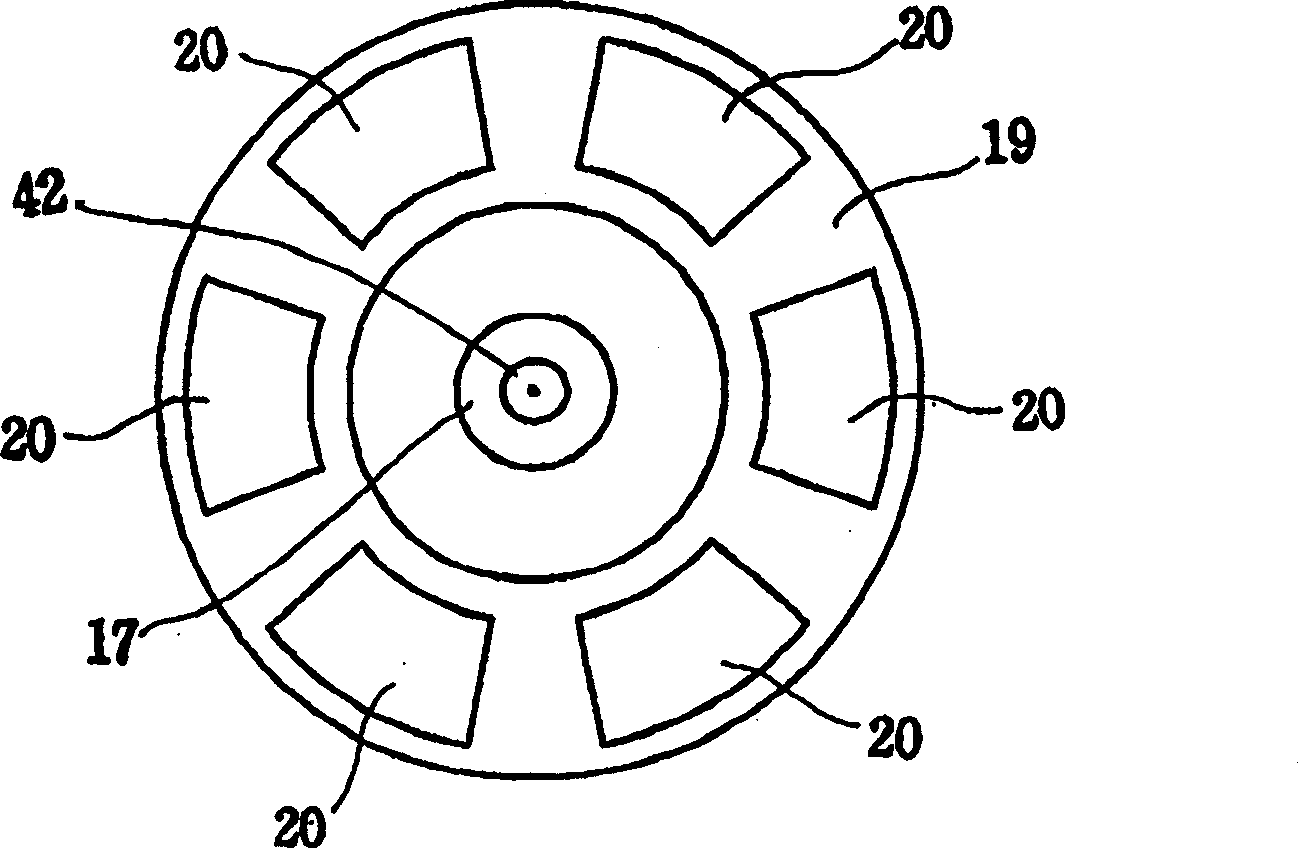

[0045] Hereinafter, an embodiment in which the combustion method and device for reducing NOx of the present invention are applied to a straight-through steam boiler as one of water tube boilers will be described with reference to the accompanying drawings. figure 1 is a longitudinal sectional view of a steam boiler to which an embodiment of the present invention is applied, figure 2 yes means figure 1 A partial cross-sectional enlargement, image 3 yes means figure 2 partial bottom view, Figure 4 shows the relationship between the NOx reduction characteristic and the water spray amount according to this example, Figure 5 shows the relationship between the NOx reduction characteristic and the water spray amount according to this example, Figure 6 Indicates the relationship between the bellows pressure characteristic and the water spray volume.

[0046] exist figure 1 Among them, the steam boiler 1 as the combustion device for reducing NOx in this embodiment is a boil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com