Speed limiting system of oil hydraulic running vehicle

A speed limit and vehicle technology, applied in control/regulation systems, vehicle accessories, vehicle components, etc., can solve the problems of increased management hours, more types, and redundant assembly hours, and achieve the effect of simple speed limit and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

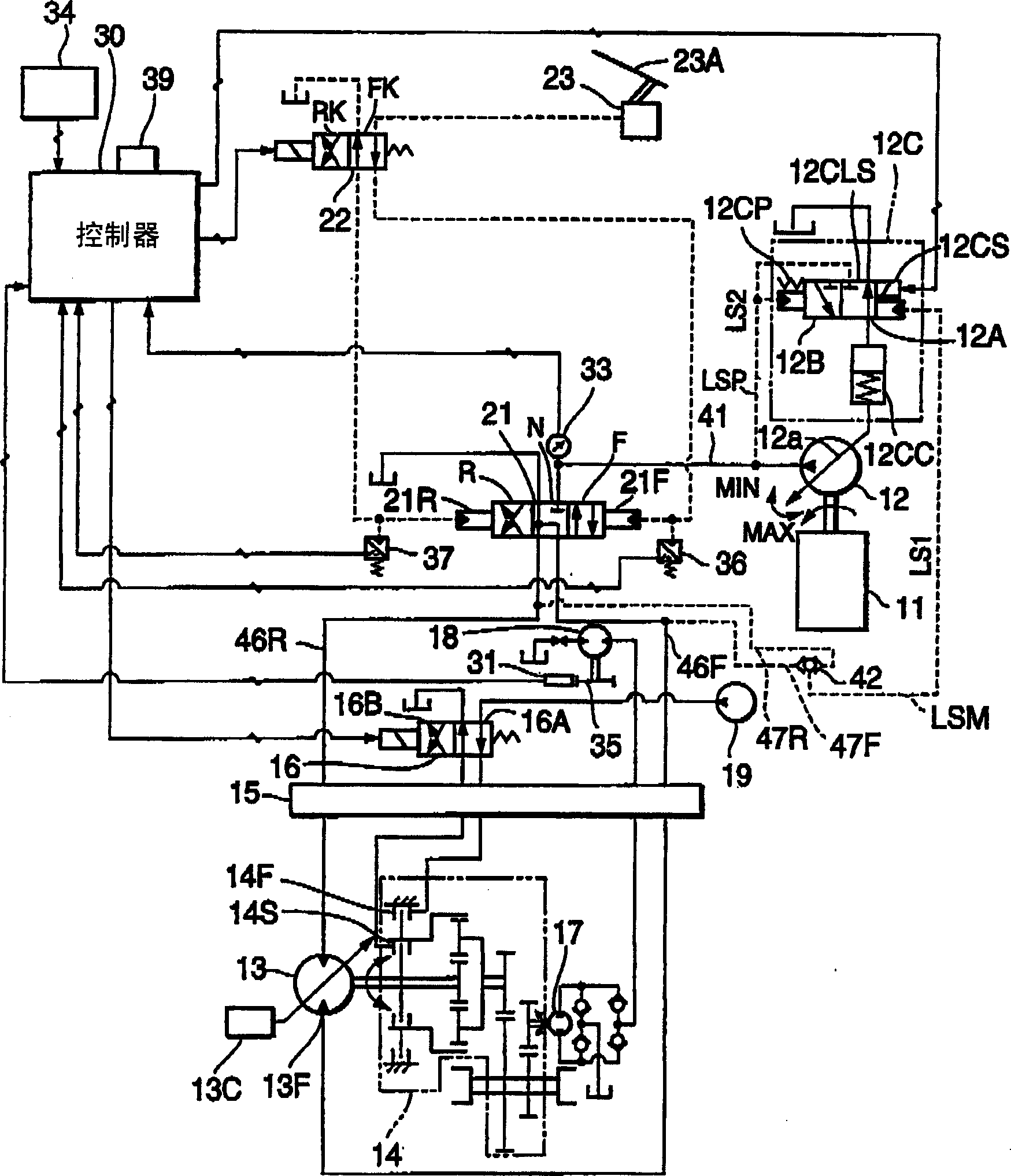

[0010] refer to figure 1 The vehicle speed limiting system of the present invention will be described in detail.

[0011] A travel pump 12 is connected to the engine 11, and the travel pump 12 is driven by the engine 11 to discharge pressure oil. Pressurized oil discharged from the travel pump 12 is sent to the travel motor 13 through the travel control valve 21 and the hydraulic rotary joint 15 . The travel motor 13 is connected to the input shaft of the gearbox 14 to drive the gearbox 14 .

[0012] The transmission 14 is provided with a travel speed detection pump 17 that rotates in proportion to the rotation of the output shaft of the transmission 14 . The pressure oil discharged from the travel speed detection pump 17 is sent to the travel speed detection motor 18 through the oil pressure rotary joint 15 . The travel pump 12 is a variable hydraulic pump and has a pump displacement control mechanism 12C. In addition, the travel motor 13 is a variable hydraulic motor and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com