Toner with positive electricity for electronic photographing and its mfg. method

A technology for electrophotography and toner, applied in the directions of developer, electrography, optics, etc., can solve the problems of poor chargeability and insulation, narrow resin selectivity, limited freedom of molecular weight distribution, etc., and achieve excellent transfer efficiency. , The effect of excellent charging stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

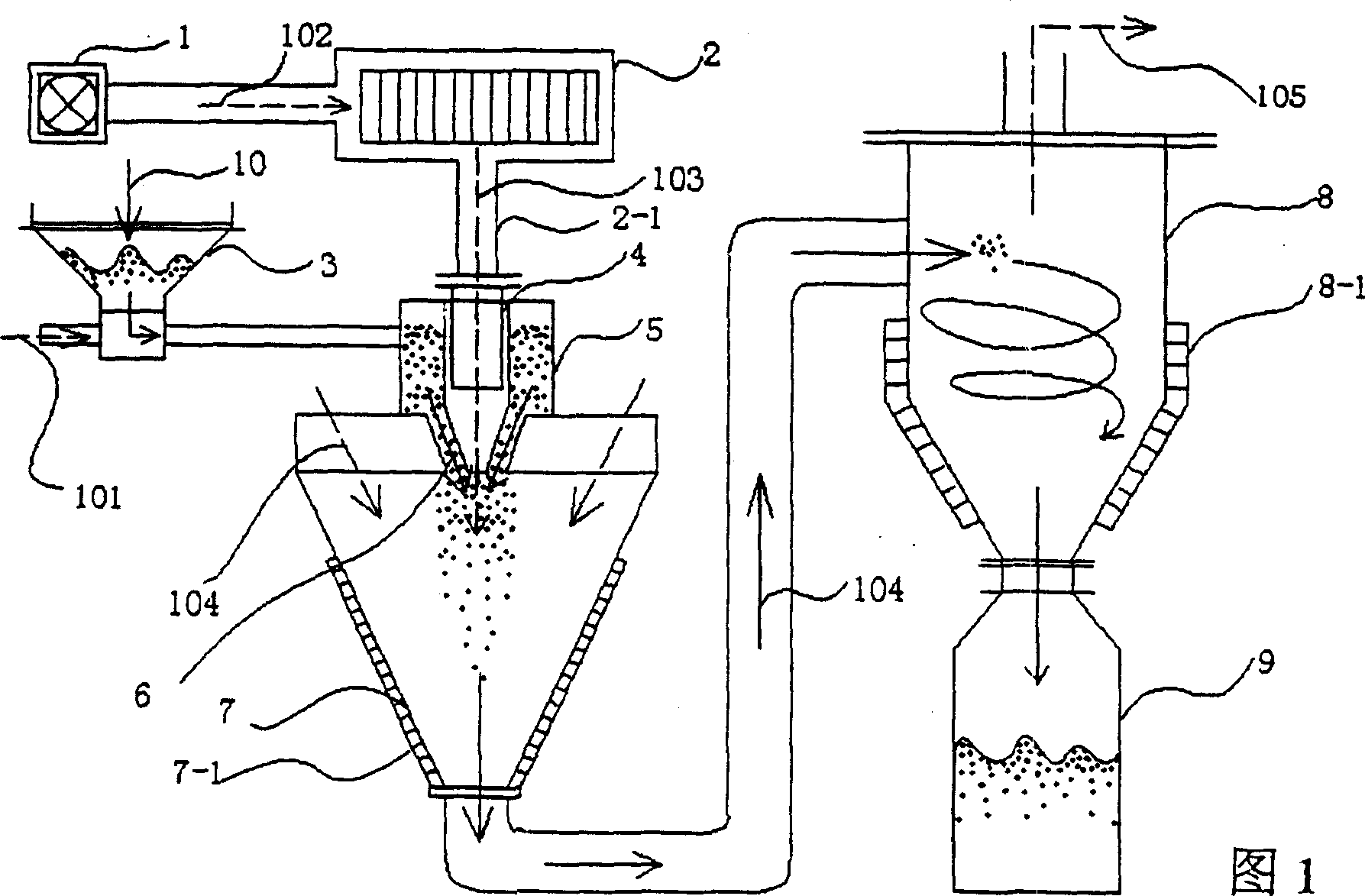

Method used

Image

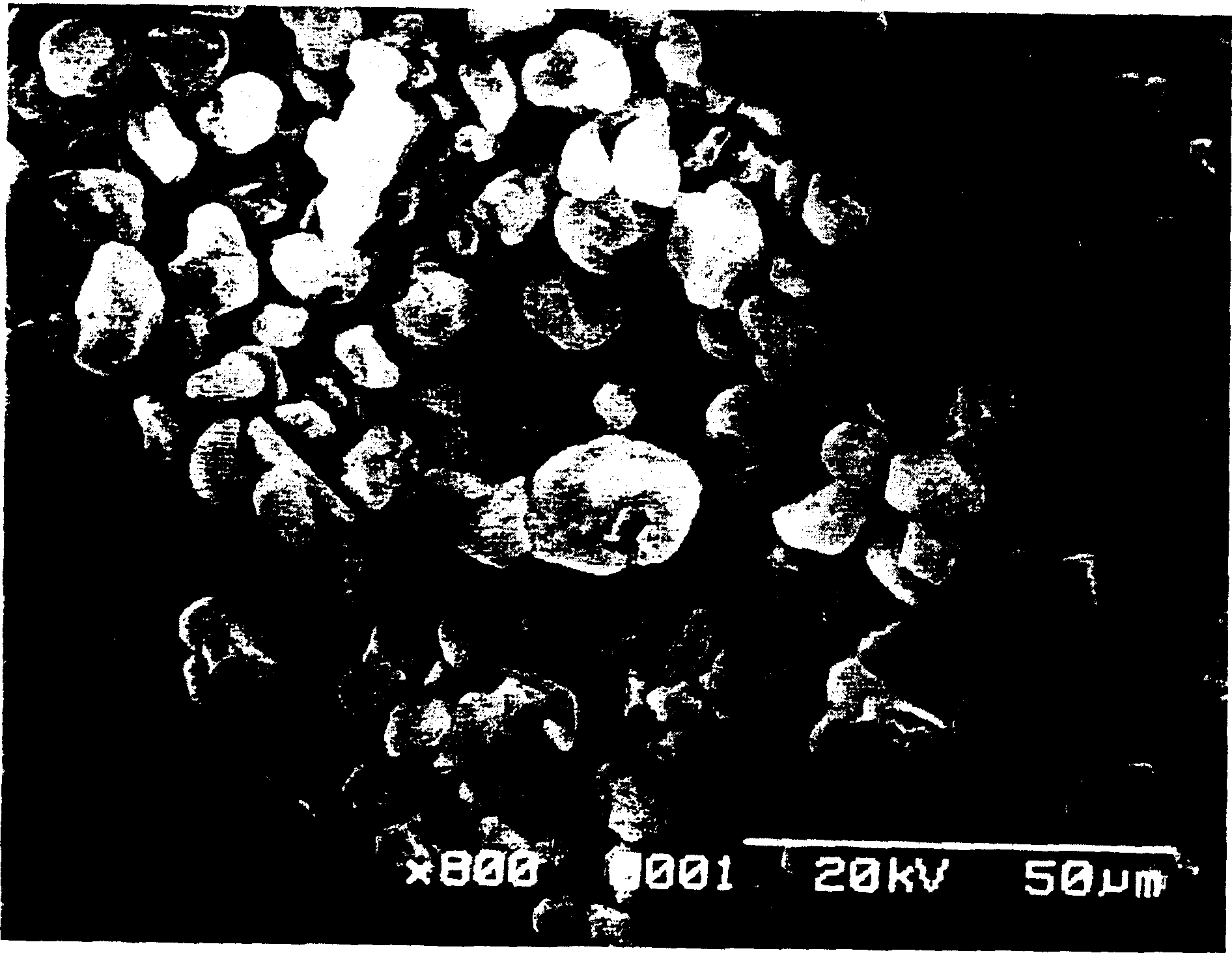

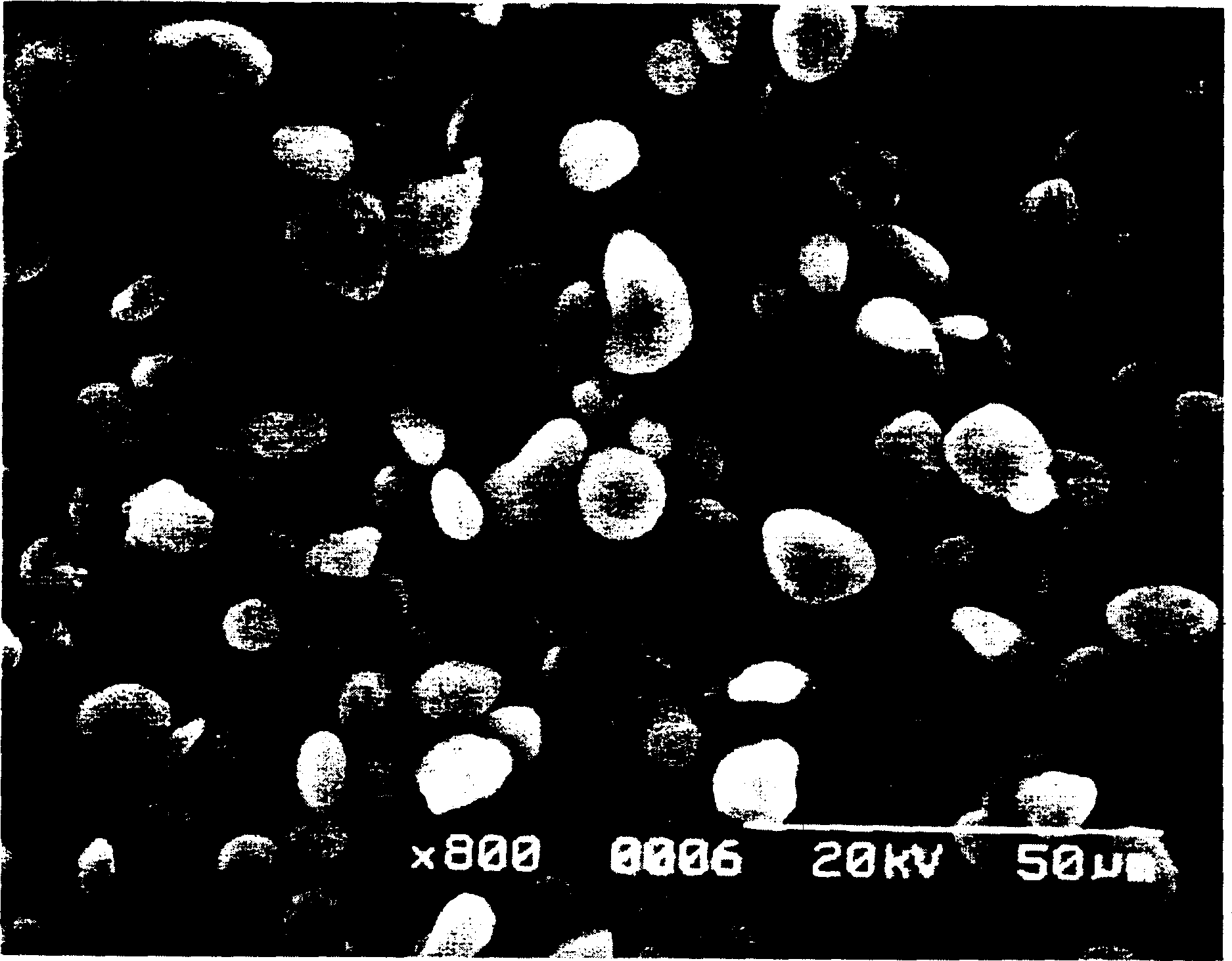

Examples

Embodiment 1

[0049] The positively charged toner for electrophotography of the present invention and its production method will be specifically described below, and the advantages of the toner according to the present invention will be described by evaluating the examples according to the present invention and comparative examples not according to the present invention. In the following description, "parts" are all expressed in parts by weight.

[0050] (Binder resin): Styrene / n-butyl acrylate copolymer

[0051] (manufactured by Mitsui Chemicals, CPR 250) 100 copies

[0052] (wax): low molecular weight polyethylene

[0053] (Mitsui Chemicals Co., Ltd. Hiwax NP-055) 5 parts

[0054] (colorant): carbon black

[0055] (Ri-Gal 330R made by Kiyabottsuto Co., Ltd.) 6 servings

[0056] (Charging regulator): Nigrosine dyes

[0057] (Bontron N-01 manufactured by Orient Chemical Co., Ltd.) 2 parts Resin having a quaternary ammonium base as a functional group

[0058] (Acryl Bees FCA-201-PS man...

Embodiment 2~4

[0067] In addition to changing according to the more preferred ratio combination described in the second aspect of the present invention, that is to say, the content of the charge regulator in Examples 2, 3, and 4 contains nigrosine dyes and resins with quaternary ammonium bases as functional groups. It carried out similarly to Example 1 except that 100 parts of binder resins were 0.6 part and 2 parts, 3 parts and 5 parts, and 5 parts and 10 parts, respectively.

Embodiment 5

[0068] (Example 5) The same procedure as in Example 1 was carried out except that the content of the resin having a quaternary ammonium base as a functional group as a charging regulator was not within the range described in the second aspect of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com