Thallum-based high-temperature superconductive film material and its preparation method

A technology of high-temperature superconducting thin films and superconducting thin films, applied in the usage of superconducting elements, manufacturing/processing of superconducting devices, superconducting devices, etc. To avoid problems such as conductive thin films, to achieve the effect of uniform and flat surface morphology and good epitaxial characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

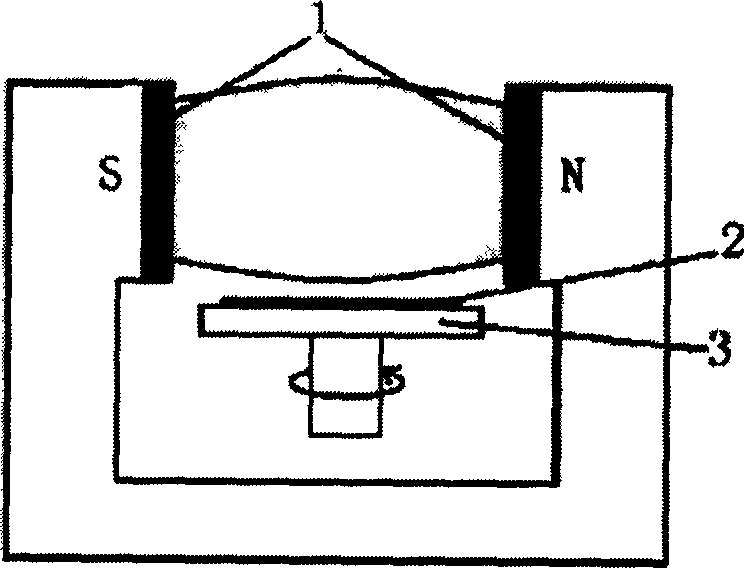

[0036] The Tl-Ba-Ca-Cu-O amorphous precursor film was prepared by DC magnetron sputtering. figure 1 is a schematic diagram of the magnetron sputtering device. In the figure, two sputtering targets 1 are placed symmetrically. The film substrate substrate 2 is placed on a rotatable substrate holder 3 .

[0037] The sputtering target 1 was produced by a two-step method. First use BaO 2 , CaO and CuO are matched according to the ratio of atomic ratio Ba: Ca: Cu = 2: 1: 2, after uniform mixing and grinding, burning in a flowing oxygen atmosphere at a temperature of 900°C for 10 hours, and then grinding carefully after cooling. BaCaCuO powder was made by firing under the same conditions for another 10 hours. Then, the BaCaCuO powder was mixed with Tl 2 o 3 The powders were mixed and grinded carefully, then pressed into tablets, sealed with a crucible, and fired in a flowing oxygen atmosphere at a temperature of 850°C for 1 hour. After cooling, carefully grind, press into tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com