Method for preparing an AlN nano-pattern template on the basis of Ni metal self-assembly

A technology of metal self-assembly and nano-patterning, applied in the direction of nanotechnology, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as high cost, time-consuming, complex process, etc., to improve photoelectric response and gain, and promote horizontal Effect of epitaxial growth and improvement of material quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

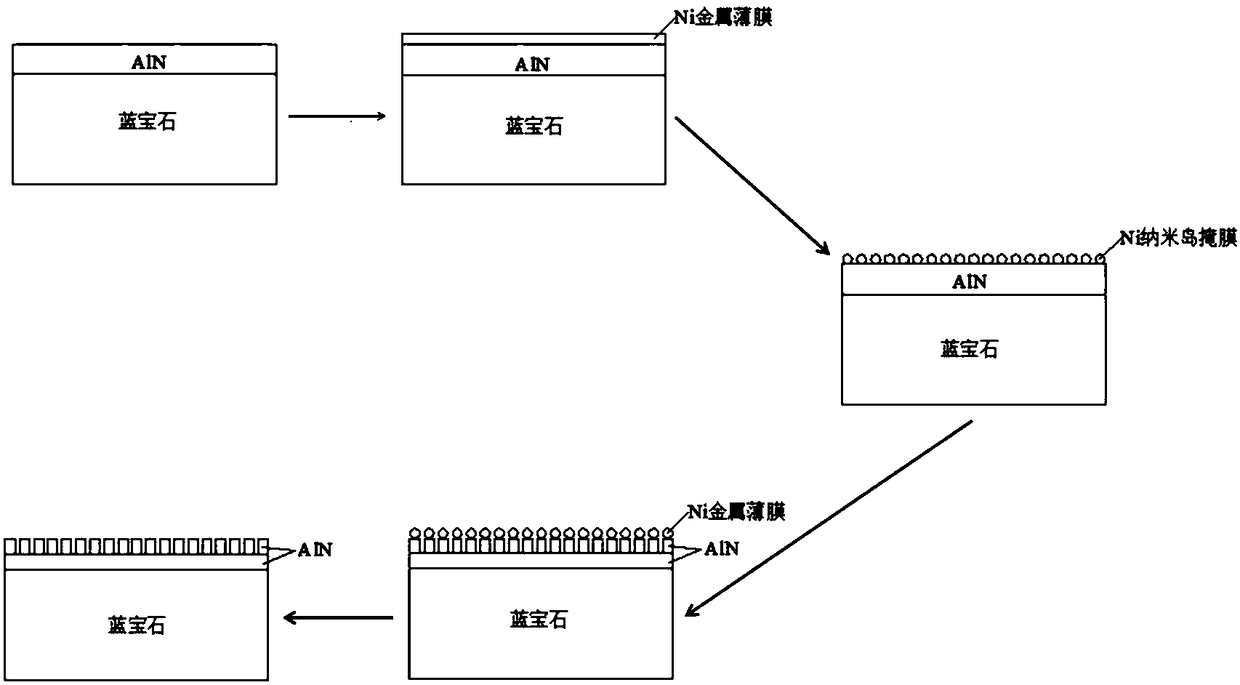

[0030] A method for preparing an AlN nano-patterned substrate based on a Ni metal self-assembly method, comprising the following steps:

[0031] (1) Treatment of the AlN substrate template: Put the 3 μm AlN / sapphire composite substrate into deionized water, ultrasonically clean it at room temperature for 10 minutes, remove the dirt particles on the surface of the AlN substrate template, and then pass through acetone, ethanol, and deionized water for 10 minutes each Ultrasonic washing once, after removing surface organic matter, blow dry with high-purity dry nitrogen;

[0032] (2) Preparation of Ni metal thin film: at a temperature of 500°C and a vacuum of 5×10 -7Under the high vacuum condition of Pa, a layer of Ni metal film with a thickness of 5 nm is evaporated on the substrate processed in step (1) by electron beam, and the evaporated metal is Ni simple substance;

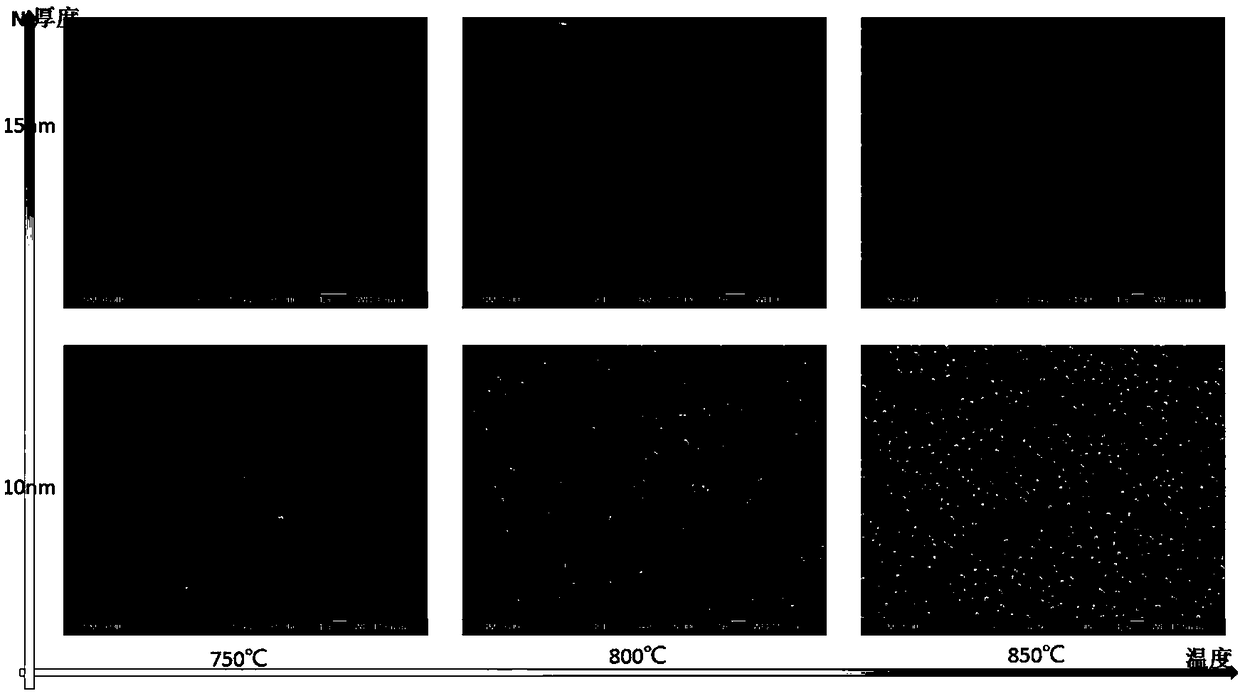

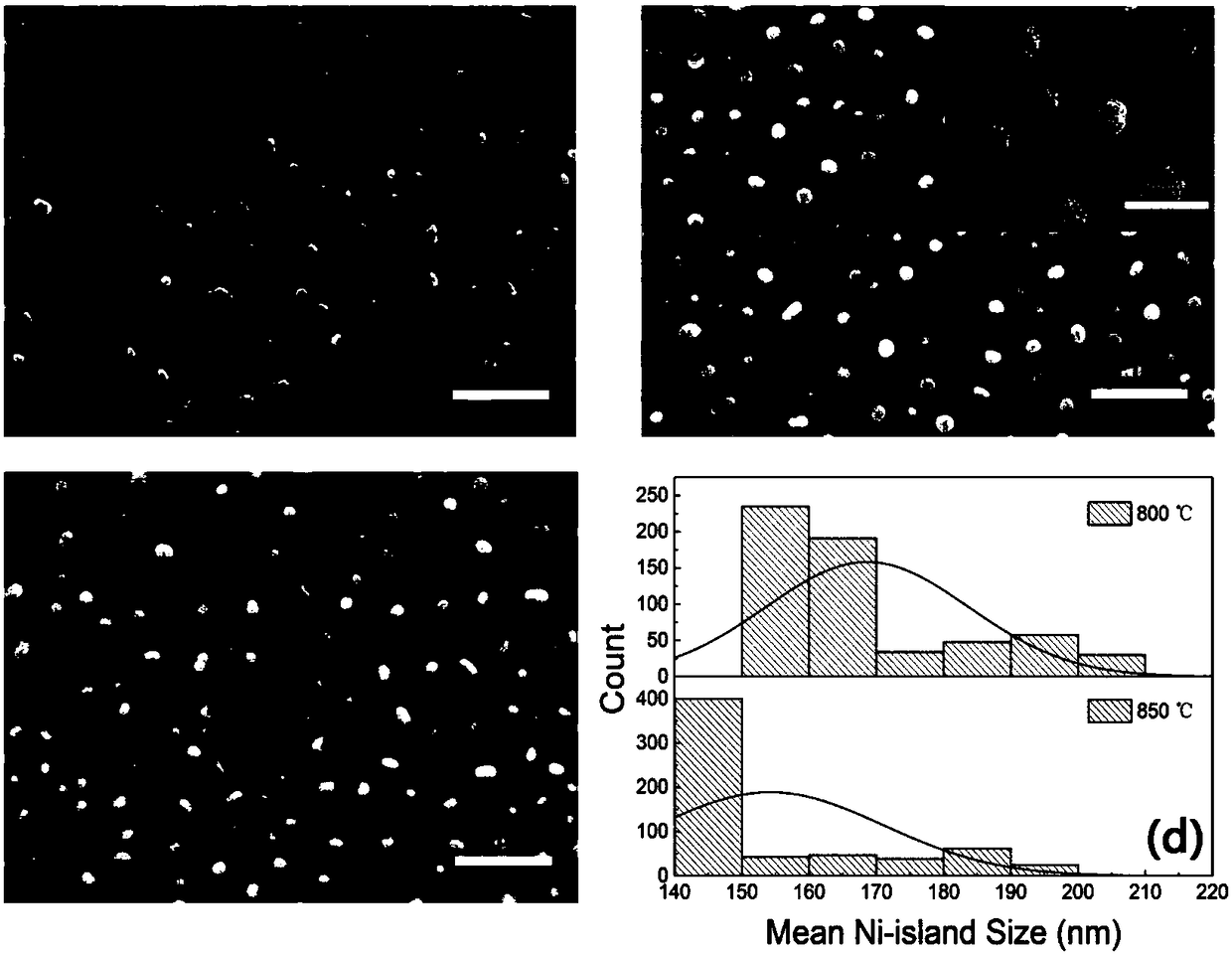

[0033] (3) Preparation of Ni nano-island mask: In a nitrogen atmosphere at a temperature of 800 °C, the meta...

Embodiment 2

[0038] The method for preparing AlN nano-patterned substrate based on Ni metal self-assembly method includes the following steps:

[0039] (1) Treatment of AlN substrate template: put the 3 μm AlN / sapphire composite substrate into deionized water, ultrasonically clean it for 10 minutes at room temperature, remove the sticky particles on the surface of the AlN substrate template, and then pass through acetone, ethanol and deionized water respectively. Each ultrasonic washing was performed for 10 minutes, and the surface organics were removed, and then dried with high-purity dry nitrogen;

[0040] (2) Preparation of Ni metal thin film: at a temperature of 500 °C and a vacuum of 5 × 10 -7 Under the high vacuum condition of Pa, a layer of Ni metal film with a thickness of 10 nm is evaporated on the substrate processed in step (1) by electron beam, and the evaporated metal is Ni simple substance;

[0041] (3) Preparation of Ni nano-island mask: In a nitrogen atmosphere at a temper...

Embodiment 3

[0045] The method for preparing AlN nano-patterned substrate based on Ni metal self-assembly method includes the following steps:

[0046] (1) Treatment of AlN substrate template: put the 3 μm AlN / sapphire composite substrate into deionized water, ultrasonically clean it for 10 minutes at room temperature, remove the sticky particles on the surface of the AlN substrate template, and then pass through acetone, ethanol and deionized water respectively. Each ultrasonic washing was performed for 10 minutes, and the surface organics were removed, and then dried with high-purity dry nitrogen;

[0047] (2) Preparation of Ni metal thin film: under high vacuum conditions at a temperature of 500 °C, the vacuum degree is 5 × 10 -7 Pa, on the substrate processed by step (1), a layer of 5nm thick Ni metal film is evaporated by electron beam;

[0048] (3) Preparation of Ni nano-island mask: at a temperature of 800 °C in a nitrogen atmosphere, the Ni metal film obtained in step (2) was subj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com