Method and apparatus with redundancies for treating substrate plastic parts to accept paint without using adhesion promoters

A technology for plastic parts and components, applied in the direction of pretreatment of surfaces, devices for coating liquids on surfaces, coatings, etc., can solve the problem of difficulty in distinguishing treated parts from untreated parts, weakening of the surface of parts, waste of materials and time and other problems, to achieve the effect of reducing overspray, suppressing demand, and reducing capital costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] While the present invention can be embodied in many forms, there are shown in the drawings a number of presently preferred embodiments and will be discussed in detail hereinafter. It should be understood that the present disclosure should be considered as illustrative of the invention and is not intended to limit the invention to the particular embodiments described. It should also be understood that the heading of this section of the disclosure ("Detailed Description") refers to the requirements of the patent office and should not be considered limiting of the subject matter disclosed herein.

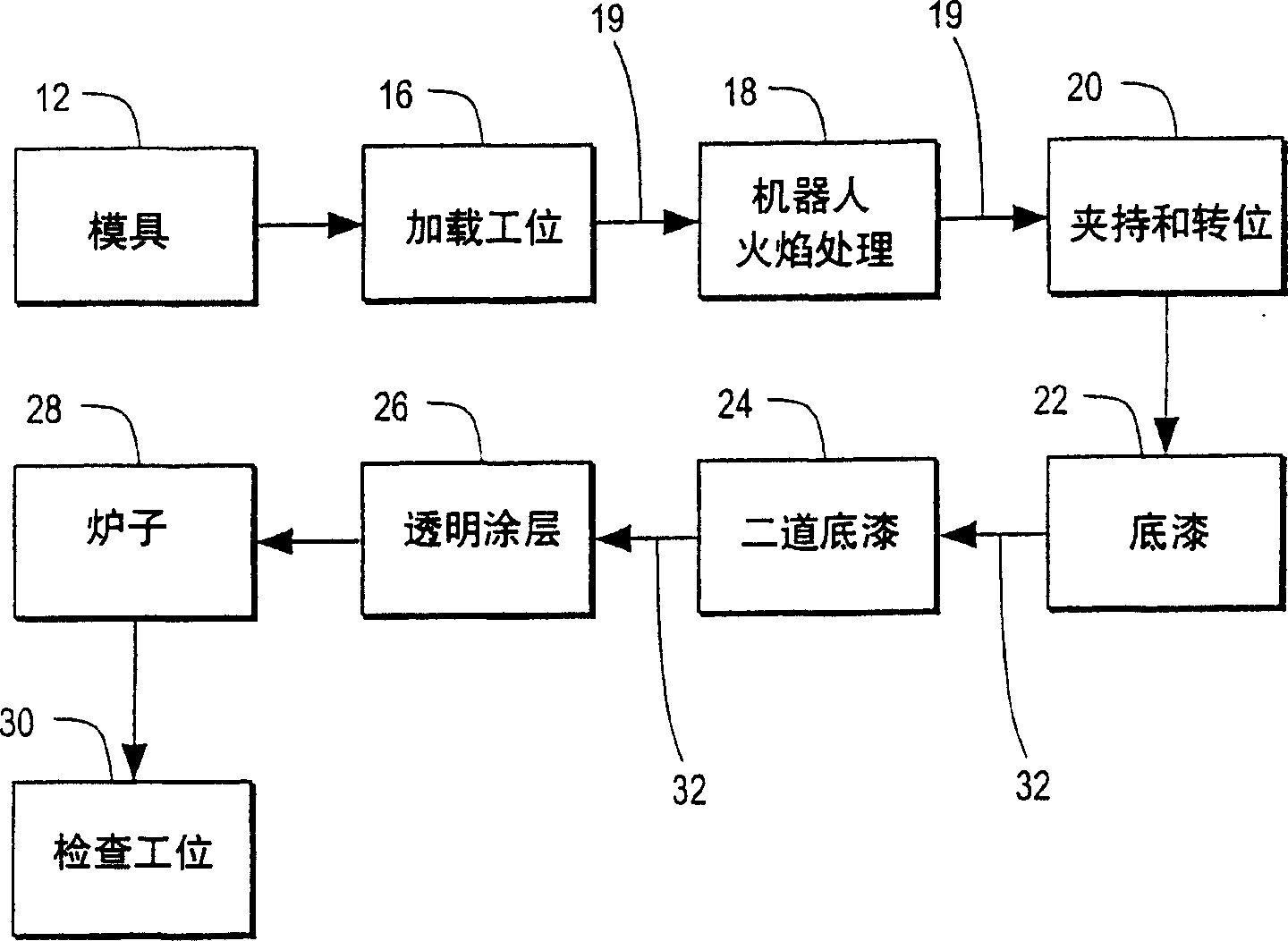

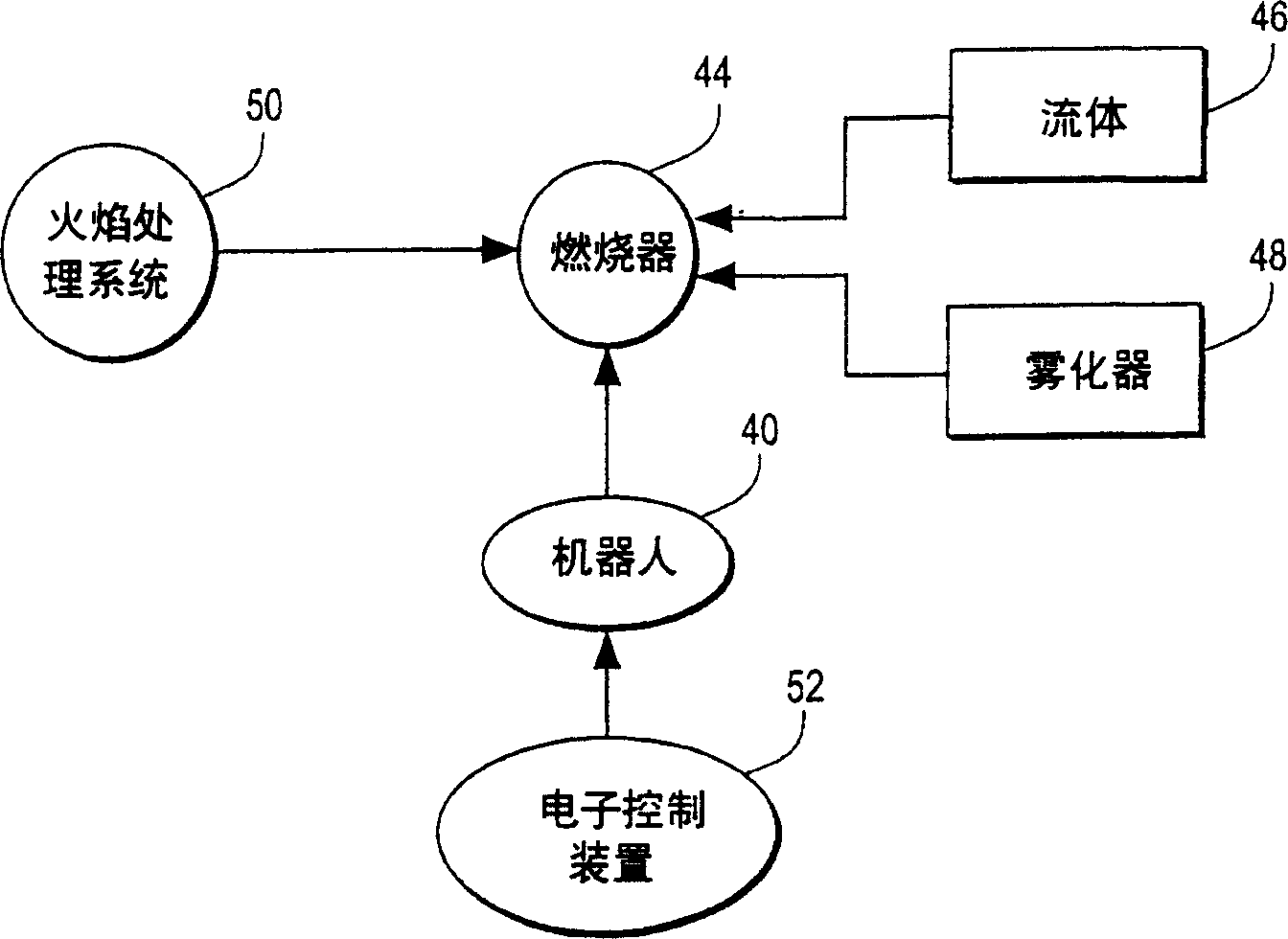

[0054] With reference to the accompanying drawings, figure 1 A schematic diagram of one embodiment of a plant 10 using the method and apparatus of the present invention is shown. In this factory 10 , the mold 12 can be used for the actual production of the objects 14 or devices which will be subsequently processed and painted in the factory 10 . Plant 10 also includes loading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com